-

-

March 4, 2020 at 3:12 pm

Sanjay1993

SubscriberI am working on a problem in Ansys r19 version and having an error - An unknown error occurred during solution. Check the Solver Output on the Solution Information object for possible causes. Can anyone help me with this ?

-

March 4, 2020 at 9:35 pm

peteroznewman

SubscriberThis site has 251 results in a Google search of the term "unknown error". Please read many of them and try at least three things you find in those discussions, then come back with a followup question.

-

March 7, 2020 at 12:26 am

Sanjay1993

SubscriberI have looked into the various solution for the error that i got, but it didn't help my work. I am certain that there is some other issue such as maybe in setting up the boundary condition or in my contact elements. Also the deformed part is appearing inside my tool of displacement. Please help me with this.

This maybe due to not defining proper contact element, is my guess although i'm not sure.. can you help me with this. I can attach the load and boundary condition for my geometry if that helps.

-

March 7, 2020 at 1:36 am

peteroznewman

SubscriberI can't tell from the image, are those shell elements on a surface with "Thick Shells and Beams" display style, or are those solid elements.

I think they are solid elements so your problem is you have only one solid element through the thickness. Don't do that. Go back to CAD and extract midsuface geometry from the solid bodies and try again by meshing shell elements on a surface.

If you want to try something on this solid model, then put at least two elements through the thickness (if they are solid elements).

Finally, for either shell or solid elements, under Analysis Settings, turn on Large Deflection and turn on Auto Time Stepping. Make the Initial Substeps 100.

-

March 10, 2020 at 7:17 pm

Sanjay1993

Subscriberthis is the video I have been following for my sample and geometry...

link: https://www.youtube.com/watch?v=svE0ZW6QrrY&t=1711s

I'm not sure about the surface elements they have used... But this is what i have been following

-

March 11, 2020 at 12:13 am

Sanjay1993

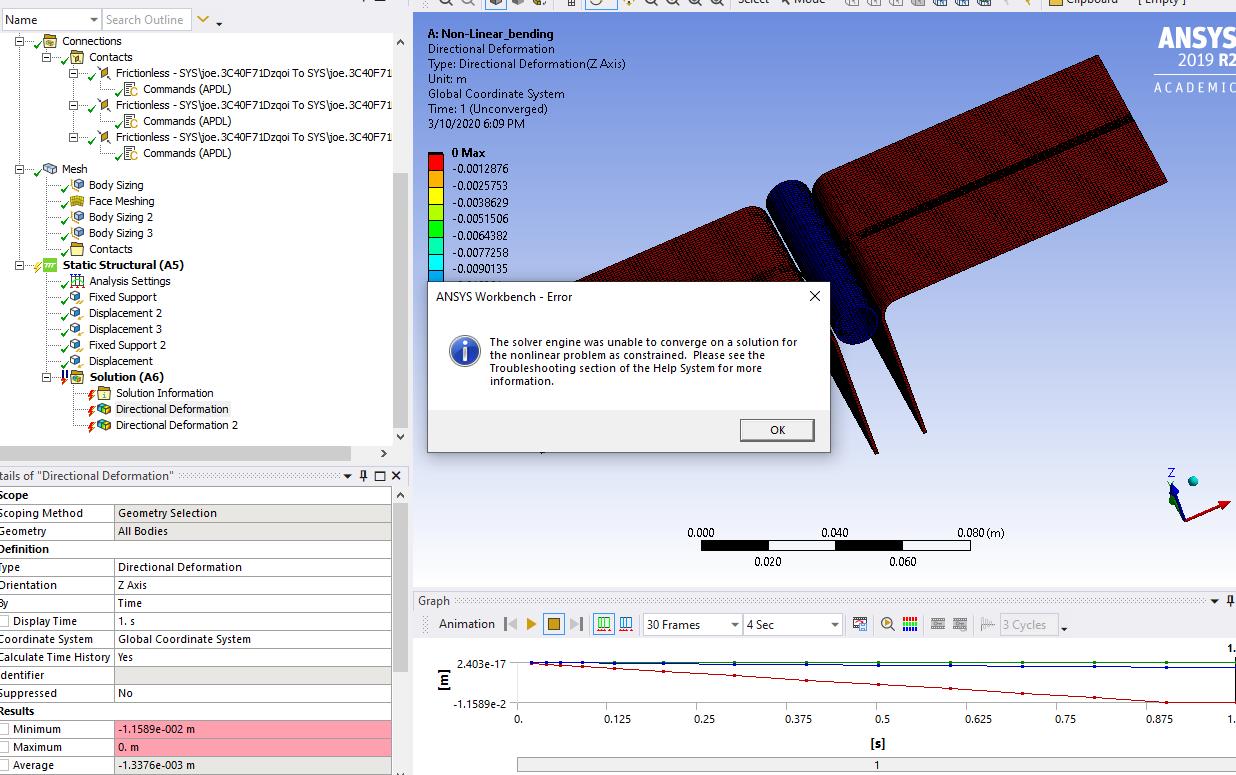

SubscriberOk..So this is the new error.. Although the job is somewhat getting done as per my test in lab. The error is: Solver engine was unable to converge on a solution for nonlinear problem as constrained . Please check troubleshooting section of the help System for more information.

-

March 11, 2020 at 12:17 am

-

March 11, 2020 at 12:19 am

-

March 24, 2020 at 5:59 pm

-

March 25, 2020 at 11:50 am

peteroznewman

SubscriberA Google search on this site for "unable to converge" has 104 results. Please read them, I expect you will find many things to try.

-

April 1, 2020 at 3:37 pm

Sanjay1993

SubscriberI have checked on internet and couldn't find any solution for the convergence applicable to my problem. Can you help me with this?

-

June 11, 2020 at 10:23 pm

Sanjay1993

SubscriberHi Peteroznewman,

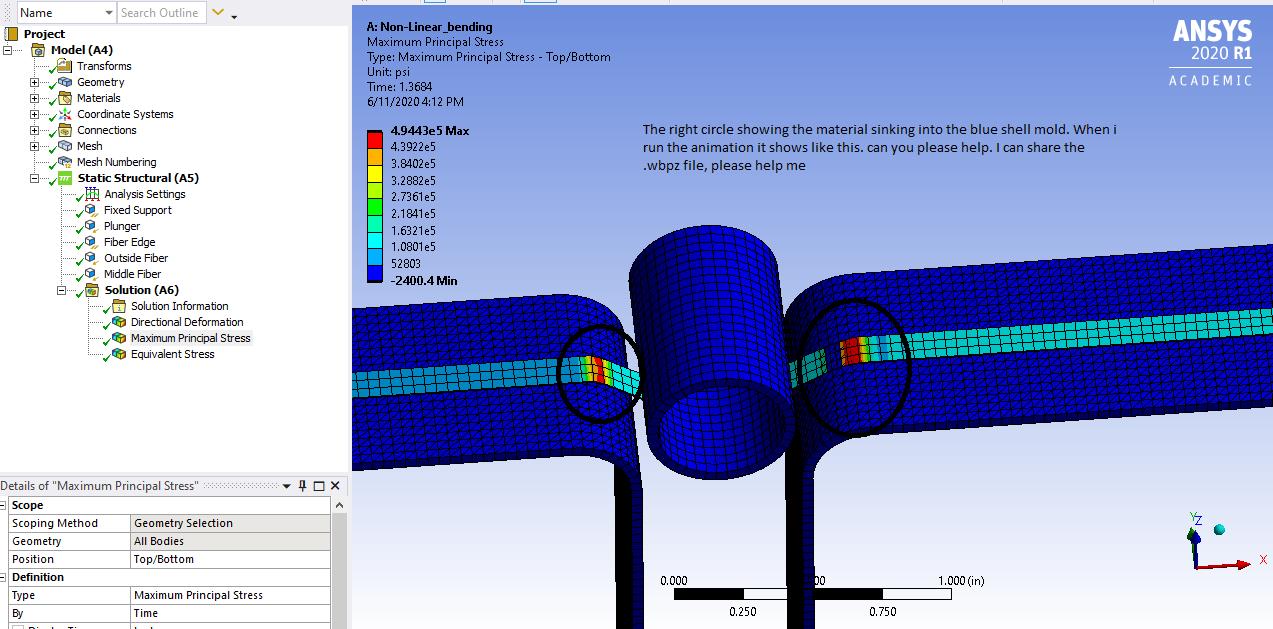

My Model right now is working with no errors but the material below the plunger seems to be sinking into the solid. I did check large deflection on and I did give a large pinball radius at contact surfaces. I dont know whether it is due to contact or mesh. Can you please check. I can send the Workbench Project Archive .wbpz file if it helps. It would be of great help.

Sanjay

-

June 12, 2020 at 12:09 pm

peteroznewman

Subscriber1. Change the strip from a solid body to a midsurface body.

2. Change the curved bodies from Flexible to Rigid.

Those two steps will greatly improve the speed of solving.

Do you have plasticity defined in the material model?

-

June 12, 2020 at 5:36 pm

Sanjay1993

SubscriberNo Plasticity is used in defining the material model. I have been also working on getting a batch code setup to run it in 2D. Although i don't understand the four variables involved here. Namely R1, R2, FTOLN,FKN. i know that these have to do with contact parameters but specifically struggling to get a grip on this.

Any ideas?

Code:

/COM, Define Element Sets

*IF,X_D,eq,2,then

*IF,X_ET,EQ,183,THEN

ET,ET_TOWS,plane183

!KEYOPT,ET_TOWS,1,2

KEYOPT,ET_TOWS,3,2

R,RP_TOWS,g_tw

*ENDIF

F_TOLN=g_tt*100

ET,ET_CNTC,CONTA172

R,RP_CNTC,0.25,1.0,1.0,F_TOLN ! R1,R2,FKN,FTOLN

ET,ET_CTRG,TARGE169

R,RP_CTRG,0.25,1.0,1.0,F_TOLN ! R1,R2,FKN,FTOLN

*ELSEIF,X_D,3,THEN

*IF,X_ET,EQ,185,THEN

ET,ET_TOWS,SOLID185 ! 8 node brick (structural)

KEYOPT,ET_TOWS,2,0 ! Full Integration

*ENDIF

*ENDIF

-

June 12, 2020 at 8:56 pm

peteroznewman

SubscriberSomeone else can answer your question. I avoid code when possible.

-

June 16, 2020 at 5:19 pm

Sanjay1993

SubscriberThis is the code that i have for a tow sample placed on a solid mold surface and a plunger deforming it. I need to figure out contacts part so that the tow does not sink into the mold surface as shown in zoomed pic. Can anyone help me with fixing the contact pair surface in order to avoid penetration.

CODE:

/title, your_ title

/prep7

! Define keypoints and geometry

k,1,0,0 ! sets a keypoint at (0,0)

k,2,5,0 ! sets a keypoint at (5,0)

k,3,15,0 ! sets a keypoint at (15,0)

k,4,1,1,0

k,5,1,3,0

k,6,4,-1,0

k,7,4,-3,0

l,1,2,5 ! creates a line with 5 divisions from keypoints 1 to 2

! you can remove lines with “ldel”

l,2,3,10 ! line with 10 divisions from point 2 to 3

l,4,5,2

l,6,7,2

k,8,5,0

l,1,4,10,,-1,0,0,0,1,0

l,8,6,10,,1,0,0,0,-1,0

! Define Material property and Mesh

et,1,3 ! sets element type 1 to beam3, the 2d beam element in ANSYS

mp,ex,1,10e6 ! sets modulus of mtl 1

mp,prxy,1,0.3 ! sets poissons ratio of mtl 1

r,1,0.75,0.0625,2.0 ! defines property set 1 for the beam element (A,I,height)

mat,1 ! sets material to 1, not needed as it defaults to 1

real,1 ! sets the property set to 1 (this is the default)

lmesh,1 ! creates a mesh of elements on line1 (undo with lclear)

lmesh,2 ! creates a mesh of elements on line 2

mp,ex,2,30e6 ! sets modulus of mtl 2

mp,prxy,2,0.3 ! sets poissons ratio of mtl 2

r,2,0.5,0.0417,1.0 ! defines property set 2 for the beam element (A,I,height)

mat,2 ! sets current material to 2

real,2

lmesh,3

lmesh,4

lmesh,5

lmesh,6

! COnstraints and Load Condition

d,7,all,0 ! constrain end

nsel,s,,,8,16 ! select elements of tow to only translate

d,all,uy,rotz,,0 ! constrains displacements of elements selected

nsel,s,,,20,22 ! select elements wall

nsel,a,,,32,41

d,all,all,0 ! constrains displacements of elements selected

nsel,s,,,17,19 ! select elements wall

nsel,a,,,23,31

nsel,a,,,1

d,all,ux,rotz,,0

f,all,fy,-110. ! applies a force of 100 units in the (–ve) Y direction

finish !exits prep7

/solu ! enters the solution phase

solve ! runs the solution

finish ! exits the solution phase

/post1 ! enter the postprocessing phase

pldisp,1 ! plot displacements over original geometry

finish ! exits post1, the postprocessor

-

- The topic ‘ANsys’ is closed to new replies.

-

5119

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.