-

-

June 13, 2023 at 8:13 am

Chandra Sekhar Narra

SubscriberHi all,

Can anyone tell me, how to give time steps(initial,minimum and maximum steps) for a creep analysis of 1000hours in Ansys?

Thanks in advance!

Kind regards

Chandra

-

June 13, 2023 at 9:02 am

-

June 13, 2023 at 9:46 am

Chandra Sekhar Narra

SubscriberHi Sampat,

Thank you very much for your response.

I understand it now. I tried what you suggested but there some problem with initial time step, minimum time step and maximum time step. Actually it is working for larger time step sizes and I would like to reduce it, then Iam getting the errors?

Could you please help me with this regard?

Kind regards

Chandra

-

June 13, 2023 at 9:54 am

Chandra Sekhar Narra

SubscriberHi Sampat,

Thank you very much for your response.

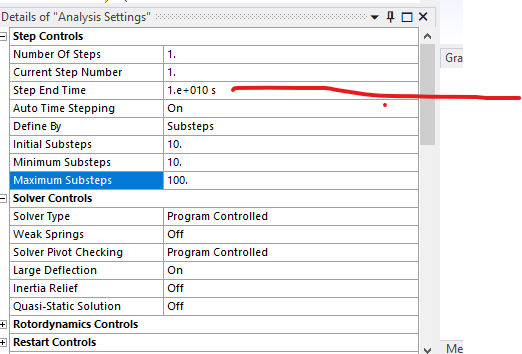

I understand it now. I tried to implement as per your suggestion. I gave initial time step, minimum time step and maximum time steps as larger values and it is working. But as far as I all these time steps sizes should be smaller values, I tried to give smaller values and am getting errors. Here am attaching the error.

Could you please help me with this regard?

Kind regards

Chandra

-

June 13, 2023 at 10:38 am

Sampat Kumar

Ansys EmployeeHi Chandra,

Will you please check the error in the solver file? . Please check the error in the solver output file and upload the screenshot too. Please upload a screenshot of the analysis setting where you have entered the time step. Please upload both the time steps that you have used for successful and unsuccessful simulations.

Regards,

Sampat -

June 13, 2023 at 11:19 am

Chandra Sekhar Narra

SubscriberHi Sampat,

I checked there, I can see only warnings but not errors. Below am attaching the screenshot of it.

Also am attaching the screenshots of Analysis settings both successful and unsuccessful simulations.

Here I posted the solution information.

Solver Output

ANSYS Mechanical

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS 14.5 LEGAL NOTICES *

***************************************************************

* *

* Copyright 2012 SAS IP, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of ANSYS, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the ANSYS, Inc. online documentation or the ANSYS, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* ANSYS, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* ANSYS, Inc. is a UL registered *

* ISO 9001:2008 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the ANSYS, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the ANSYS, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

***** ANSYS COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

4 PARALLEL CPUS REQUESTED

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

00408972 VERSION=WINDOWS x64 RELEASE= 14.5 UP20120918

CURRENT JOBNAME=file 10:36:58 JUN 13, 2023 CP= 3.297

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

DO NOT WRITE ELEMENT RESULTS INTO DATABASE

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 10.6161111

TITLE=

teststatic--Static Structural (C5)

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = J:\Projekte\18\18-020_AIF_FOGI_FlexOfenbetrw\4_Simulation\FEM_mechanical\Chandra\Draft\REFTIMESTEP\ChandraREfe1\_ProjectScratch\Scr26D5\

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = J:\Projekte\18\18-020_AIF_FOGI_FlexOfenbetrw\4_Simulation\FEM_mechanical\Chandra\Draft\REFTIMESTEP\ChandraREfe1\teststatic_files\dp0\SYS-3\MECH\

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = J:\Projekte\18\18-020_AIF_FOGI_FlexOfenbetrw\4_Simulation\FEM_mechanical\Chandra\Draft\REFTIMESTEP\ChandraREfe1\teststatic_files\user_files\

--- Data in consistent MKS units.

MKS UNITS SPECIFIED FOR INTERNAL

LENGTH (l) = METER (M)

MASS (M) = KILOGRAM (KG)

TIME (t) = SECOND (SEC)

TEMPERATURE (T) = CELSIUS (C)

TOFFSET = 273.0

CHARGE (Q) = COULOMB

FORCE (f) = NEWTON (N) (KG-M/SEC2)

HEAT = JOULE (N-M)

PRESSURE = PASCAL (NEWTON/M**2)

ENERGY (W) = JOULE (N-M)

POWER (P) = WATT (N-M/SEC)

CURRENT (i) = AMPERE (COULOMBS/SEC)

CAPACITANCE (C) = FARAD

INDUCTANCE (L) = HENRY

MAGNETIC FLUX = WEBER

RESISTANCE (R) = OHM

ELECTRIC POTENTIAL = VOLT

INPUT UNITS ARE ALSO SET TO MKS

1

***** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 14.5 *****

ANSYS Mechanical

00408972 VERSION=WINDOWS x64 10:36:58 JUN 13, 2023 CP= 3.391

teststatic--Static Structural (C5)

***** ANSYS ANALYSIS DEFINITION (PREP7) *****

*********** Nodes for the whole assembly ***********

*********** Elements for Body 1 "Probe_Teil3" ***********

*********** Send User Defined Coordinate System(s) ***********

*********** Set Reference Temperature ***********

*********** Send Materials ***********

IMPLICIT CREEP OPTION is used, CREEP MODEL is 10

*********** Fixed Supports ***********

*********** Define Force Using Surface Effect Elements ***********

*********** Define Body Force Temperature ***********

***** ROUTINE COMPLETED ***** CP = 6.156

--- Number of total nodes = 70239

--- Number of contact elements = 189

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 41056

--- Number of total elements = 41245

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 10.6166667

****************************************************************************

************************* SOLUTION ********************************

****************************************************************************

***** ANSYS SOLUTION ROUTINE *****

PERFORM A STATIC ANALYSIS

THIS WILL BE A NEW ANALYSIS

LARGE DEFORMATION ANALYSIS

NEW SOLUTION CONTROL OPTION IS ACTIVATED,

THE FOLLOWING COMMANDS ARE RESET TO NEW DEFAULTS:

AUTOTS, DELTIM, NSUB, CNVTOL, LNSRCH, PRED, NROPT,

TINTP, CUTCONTROL, OPNCONTROL, MONITOR, NEQIT, SSTIF, KBC.

CONTACT TIME PREDICTIONS ARE BASED ON ELEMENT KEYOPT(7) SPECIFIED

USE SPARSE MATRIX DIRECT SOLVER

CONTACT INFORMATION PRINTOUT LEVEL 1

NLDIAG: Nonlinear diagnostics CONT option is set to ON.

Writing frequency : each ITERATION.

DEFINE RESTART CONTROL FOR LOADSTEP LAST

AT FREQUENCY OF LAST AND NUMBER FOR OVERWRITE IS 0

DELETE RESTART FILES OF ENDSTEP

****************************************************

******************* SOLVE FOR LS 1 ****************

SELECT FOR ITEM=TYPE COMPONENT=

IN RANGE 2 TO 2 STEP 1

189 ELEMENTS (OF 41245 DEFINED) SELECTED BY ESEL COMMAND.

SELECT ALL NODES HAVING ANY ELEMENT IN ELEMENT SET.

426 NODES (OF 70239 DEFINED) SELECTED FROM

189 SELECTED ELEMENTS BY NSLE COMMAND.

SPECIFIED SURFACE LOAD PRES FOR ALL SELECTED ELEMENTS LKEY = 1 KVAL = 1

SET ACCORDING TO TABLE PARAMETER = _LOADVARI41X

SPECIFIED SURFACE LOAD PRES FOR ALL SELECTED ELEMENTS LKEY = 2 KVAL = 1

SET ACCORDING TO TABLE PARAMETER = _LOADVARI41Y

SPECIFIED SURFACE LOAD PRES FOR ALL SELECTED ELEMENTS LKEY = 3 KVAL = 1

SET ACCORDING TO TABLE PARAMETER = _LOADVARI41Z

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 70239 STEP 1

70239 NODES (OF 70239 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 41245 STEP 1

41245 ELEMENTS (OF 41245 DEFINED) SELECTED BY ESEL COMMAND.

PRINTOUT RESUMED BY /GOP

SELECT COMPONENT _CM43

SELECT ALL NODES HAVING ANY ELEMENT IN ELEMENT SET.

70239 NODES (OF 70239 DEFINED) SELECTED FROM

41056 SELECTED ELEMENTS BY NSLE COMMAND.

SPECIFIED BODY FORCE TEMP FOR ALL SELECTED NODES SET ACCORDING TO

TABLE PARAMETER = _LOADVARI43

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 70239 STEP 1

70239 NODES (OF 70239 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 41245 STEP 1

41245 ELEMENTS (OF 41245 DEFINED) SELECTED BY ESEL COMMAND.

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE INITIAL TIME STEP SIZE OF 1.000000 FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 0.1000000 AS THE MINIMUM TIME STEP SIZE

USE 1.000000 AS THE MAXIMUM TIME STEP SIZE

TIME= 1.0000

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE STRS ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPEL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPPL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPTH ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPCR ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

NONLINEAR STABILIZATION CONTROL:

KEY=OFF

DO NOT INCLUDE STRAIN RATE EFFECT ON ANALYSIS FROM THIS LOAD STEP ONWARDS (VISCOPLASTICITY/CREEP ANALYSIS).

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

***** ANSYS SOLVE COMMAND *****

*** WARNING *** CP = 6.453 TIME= 10:37:00

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** CP = 6.641 TIME= 10:37:00

The model data was checked and warning messages were found.

Please review output or errors file (

J:\Projekte\18\18-020_AIF_FOGI_FlexOfenbetrw\4_Simulation\FEM_mechanica

l\Chandra\Draft\REFTIMESTEP\ChandraREfe1\_ProjectScratch\Scr26D5\file.e

err ) for these warning messages.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

--- GIVE SUGGESTIONS AND RESET THE KEY OPTIONS ---

ELEMENT TYPE 1 IS SOLID187. IT IS NOT ASSOCIATED WITH FULLY INCOMPRESSIBLE

HYPERELASTIC MATERIALS. NO SUGGESTION IS AVAILABLE AND NO RESETTING IS NEEDED.

1

***** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 14.5 *****

ANSYS Mechanical

00408972 VERSION=WINDOWS x64 10:37:00 JUN 13, 2023 CP= 6.703

teststatic--Static Structural (C5)

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

NONLINEAR GEOMETRIC EFFECTS . . . . . . . . . .ON

EQUATION SOLVER OPTION. . . . . . . . . . . . .SPARSE

CREEP MATERIAL PROPERTIES INCLUDED. . . . . . .YES

NEWTON-RAPHSON OPTION . . . . . . . . . . . . .PROGRAM CHOSEN

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** WARNING *** CP = 6.875 TIME= 10:37:01

Material number 2 (used by element 41057 ) should normally have at

least one MP or one TB type command associated with it. Output of

energy by material may not be available.

*** NOTE *** CP = 7.000 TIME= 10:37:01

The step data was checked and warning messages were found.

Please review output or errors file (

J:\Projekte\18\18-020_AIF_FOGI_FlexOfenbetrw\4_Simulation\FEM_mechanica

l\Chandra\Draft\REFTIMESTEP\ChandraREfe1\_ProjectScratch\Scr26D5\file.e

err ) for these warning messages.

*** NOTE *** CP = 7.000 TIME= 10:37:01

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** NOTE *** CP = 7.016 TIME= 10:37:01

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 1.0000

AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON

STARTING TIME STEP SIZE. . . . . . . . . . . 1.0000

MINIMUM TIME STEP SIZE . . . . . . . . . . . 0.10000

MAXIMUM TIME STEP SIZE . . . . . . . . . . . 1.0000

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

STRESS-STIFFENING . . . . . . . . . . . . . . . ON

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CREEP CRITERION . . . . . . . . . . . . . . . . none

CONVERGENCE CONTROLS. . . . . . . . . . . . . .USE DEFAULTS

COPY INTEGRATION POINT VALUES TO NODE . . . . .YES, FOR ELEMENTS WITH

ACTIVE MAT. NONLINEARITIES

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

STRS ALL

EPEL ALL

EPPL ALL

EPTH ALL

EPCR ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 22, BY SOLUTION CONTROL LOGIC.

**** CENTER OF MASS, MASS, AND MASS MOMENTS OF INERTIA ****

CALCULATIONS ASSUME ELEMENT MASS AT ELEMENT CENTROID

TOTAL MASS = 0.19112

MOM. OF INERTIA MOM. OF INERTIA

CENTER OF MASS ABOUT ORIGIN ABOUT CENTER OF MASS

XC = -0.10619 IXX = 0.3672E-04 IXX = 0.4264E-05

YC = 0.11654E-01 IYY = 0.2852E-02 IYY = 0.6904E-03

ZC = -0.58301E-02 IZZ = 0.2871E-02 IZZ = 0.6905E-03

IXY = 0.2365E-03 IXY = 0.1628E-08

IYZ = 0.1299E-04 IYZ = -0.3473E-10

IZX = -0.1183E-03 IZX = -0.9838E-10

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 0.191125

Range of element maximum matrix coefficients in global coordinates

Maximum = 5.886034316E+09 at element 41035.

Minimum = 65445040.8 at element 2557.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 41056 SOLID187 31.734 0.000773

2 189 SURF154 0.234 0.001240

Time at end of element matrix formulation CP = 20.859375.

ALL CURRENT ANSYS DATA WRITTEN TO FILE NAME= file.rdb

FOR POSSIBLE RESUME FROM THIS POINT

FORCE CONVERGENCE VALUE = 0.1614 CRITERION= 0.8234E-03

SPARSE MATRIX DIRECT SOLVER.

Number of equations = 210162, Maximum wavefront = 291

*** NOTE *** CP = 25.422 TIME= 10:37:12

The initial memory allocation (-m) has been exceeded.

Supplemental memory allocations are being used.

Memory allocated for solver = 1142.858 MB

Memory required for in-core = 989.487 MB

Optimal memory required for out-of-core = 83.514 MB

Minimum memory required for out-of-core = 43.605 MB

*** NOTE *** CP = 25.641 TIME= 10:37:12

The Sparse Matrix solver is currently running in the in-core memory

mode. This memory mode uses the most amount of memory in order to

avoid using the hard drive as much as possible, which most often

results in the fastest solution time. This mode is recommended if

enough physical memory is present to accommodate all of the solver

data.

curEqn= 75168 totEqn= 210162 Job CP sec= 37.891

Factor Done= 50% Factor Wall sec= 2.806 rate=20008.4 Mflops

curEqn= 210162 totEqn= 210162 Job CP sec= 50.562

Factor Done= 100% Factor Wall sec= 5.968 rate=18639.3 Mflops

Sparse solver maximum pivot= 5.885850936E+09 at node 15690 UY.

Sparse solver minimum pivot= 92391.3386 at node 9092 UZ.

Sparse solver minimum pivot in absolute value= 92391.3386 at node 9092

UZ.

DISP CONVERGENCE VALUE = 0.1490E-01 CRITERION= 0.4978E-05

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.9956E-04

FORCE CONVERGENCE VALUE = 3.778 CRITERION= 0.8744E-01

DISP CONVERGENCE VALUE = 0.4000E-05 CRITERION= 0.4978E-05 <<< CONVERGED

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.2861E-07

FORCE CONVERGENCE VALUE = 0.1547E-05 CRITERION= 0.8922E-01 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 41056 SOLID187 26.359 0.000642

2 189 SURF154 0.062 0.000331

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 41056 SOLID187 0.641 0.000016

2 189 SURF154 0.000 0.000000

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 2

*** TIME = 1.00000 TIME INC = 1.00000

*** ANSYS BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

136.438 MB WRITTEN ON ELEMENT SAVED DATA FILE: file.esav

107.188 MB WRITTEN ON ASSEMBLED MATRIX FILE: file.full

51.125 MB WRITTEN ON RESULTS FILE: file.rst

*************** Write FE CONNECTORS *********

WRITE OUT CONSTRAINT EQUATIONS TO FILE= file.ce

****************************************************

*************** FINISHED SOLVE FOR LS 1 *************

****************************************************

******************* SOLVE FOR LS 2 ****************

PRINTOUT RESUMED BY /GOP

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE INITIAL TIME STEP SIZE OF 1.000000 FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 1.000000 AS THE MINIMUM TIME STEP SIZE

USE 10.00000 AS THE MAXIMUM TIME STEP SIZE

TIME= 0.36000E+07

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE STRS ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPEL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPPL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPTH ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPCR ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

NONLINEAR STABILIZATION CONTROL:

KEY=OFF

INCLUDE STRAIN RATE EFFECT ON ANALYSIS FROM THIS LOAD STEP ONWARDS (VISCOPLASTICITY/CREEP ANALYSIS).

IMPLICIT CREEP RATIO CONTROL = 1.000

***** ANSYS SOLVE COMMAND *****

*** WARNING *** CP = 108.016 TIME= 10:37:42

Material number 2 (used by element 41057 ) should normally have at

least one MP or one TB type command associated with it. Output of

energy by material may not be available.

*** NOTE *** CP = 108.203 TIME= 10:37:42

The step data was checked and warning messages were found.

Please review output or errors file (

J:\Projekte\18\18-020_AIF_FOGI_FlexOfenbetrw\4_Simulation\FEM_mechanica

l\Chandra\Draft\REFTIMESTEP\ChandraREfe1\_ProjectScratch\Scr26D5\file.e

err ) for these warning messages.

*** NOTE *** CP = 108.203 TIME= 10:37:42

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

1

***** ANSYS - ENGINEERING ANALYSIS SYSTEM RELEASE 14.5 *****

ANSYS Mechanical

00408972 VERSION=WINDOWS x64 10:37:45 JUN 13, 2023 CP= 112.500

teststatic--Static Structural (C5)

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 2

TIME AT END OF THE LOAD STEP. . . . . . . . . . 0.36000E+07

AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON

STARTING TIME STEP SIZE. . . . . . . . . . . 1.0000

MINIMUM TIME STEP SIZE . . . . . . . . . . . 1.0000

MAXIMUM TIME STEP SIZE . . . . . . . . . . . 10.000

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

STRESS-STIFFENING . . . . . . . . . . . . . . . ON

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CREEP CRITERION . . . . . . . . . . . . . . . . 1.0000

CONVERGENCE CONTROLS. . . . . . . . . . . . . .USE DEFAULTS

COPY INTEGRATION POINT VALUES TO NODE . . . . .YES, FOR ELEMENTS WITH

ACTIVE MAT. NONLINEARITIES

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

STRS ALL

EPEL ALL

EPPL ALL

EPTH ALL

EPCR ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 22, BY SOLUTION CONTROL LOGIC.

FORCE CONVERGENCE VALUE = 0.1547E-05 CRITERION= 0.8569E-01

DISP CONVERGENCE VALUE = 0.9295E-09 CRITERION= 0.4978E-05 <<< CONVERGED

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.7226E-11

FORCE CONVERGENCE VALUE = 0.4362E-11 CRITERION= 0.8743E-01 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

*** LOAD STEP 2 SUBSTEP 1 COMPLETED. CUM ITER = 3

*** TIME = 2.00000 TIME INC = 1.00000

*** CREEP RATIO = 0.2626E-14 CRITERION FOR CREEP RATIO CONTROL = 1.000

*** AUTO STEP TIME: NEXT TIME INC = 1.0000 UNCHANGED

FORCE CONVERGENCE VALUE = 0.1547E-05 CRITERION= 0.8569E-01

DISP CONVERGENCE VALUE = 0.9295E-09 CRITERION= 0.4978E-05 <<< CONVERGED

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.7226E-11

FORCE CONVERGENCE VALUE = 0.4359E-11 CRITERION= 0.8743E-01 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

*** LOAD STEP 2 SUBSTEP 2 COMPLETED. CUM ITER = 4

*** TIME = 3.00000 TIME INC = 1.00000

*** CREEP RATIO = 0.2634E-14 CRITERION FOR CREEP RATIO CONTROL = 1.000

*** AUTO TIME STEP: NEXT TIME INC = 1.5000 INCREASED (FACTOR = 1.5000)

FORCE CONVERGENCE VALUE = 0.1554E-10 CRITERION= 0.8569E-01

DISP CONVERGENCE VALUE = 0.1240E-14 CRITERION= 0.4978E-05 <<< CONVERGED

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.9581E-17Thank you!

Kind regards

Chandra

-

June 14, 2023 at 4:44 pm

Sampat Kumar

Ansys EmployeeHi Chandra,

There might be a possibility that the minimum time steps that you provided are not enough to converge the problem, and the solver may require more iteration steps to converge the problem. We usually increase the sub-steps if the solution is not converging. If you are able to get the solution as per your expectations in the required time, then it's good to follow that.

Regards,

Sampat -

June 15, 2023 at 9:42 am

Chandra Sekhar Narra

SubscriberHi Sampat,

I understand it now.Thank you very much for clarification.

I will follow this.

Kind regards

Chandra

-

June 15, 2023 at 10:04 am

Sampat Kumar

Ansys EmployeeHi Chandra,

you can also check that When you decrease the end time of the simulation, in that case, you can try to lower the minimum time step and increase the maximum time step in the simulation. This will not change your simulation result but the solver will get the required steps for iteration to converge the simulation.

Regards,

Sampat -

June 15, 2023 at 10:19 am

Chandra Sekhar Narra

SubscriberHi Sampat,

I will check this and I think what you said is correct, I tried this before, lower initial and minimum time steps had worked for lesser step end time without any errors.

Thanks for much clarification.

Kind regards

Chandra

-

- The topic ‘About time steps’ is closed to new replies.

-

5124

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.