TAGGED: 3d, 3d-anayls-s, convergence, static-structural

-

-

April 25, 2024 at 2:30 pm

Pedro Miguel Gonçalves

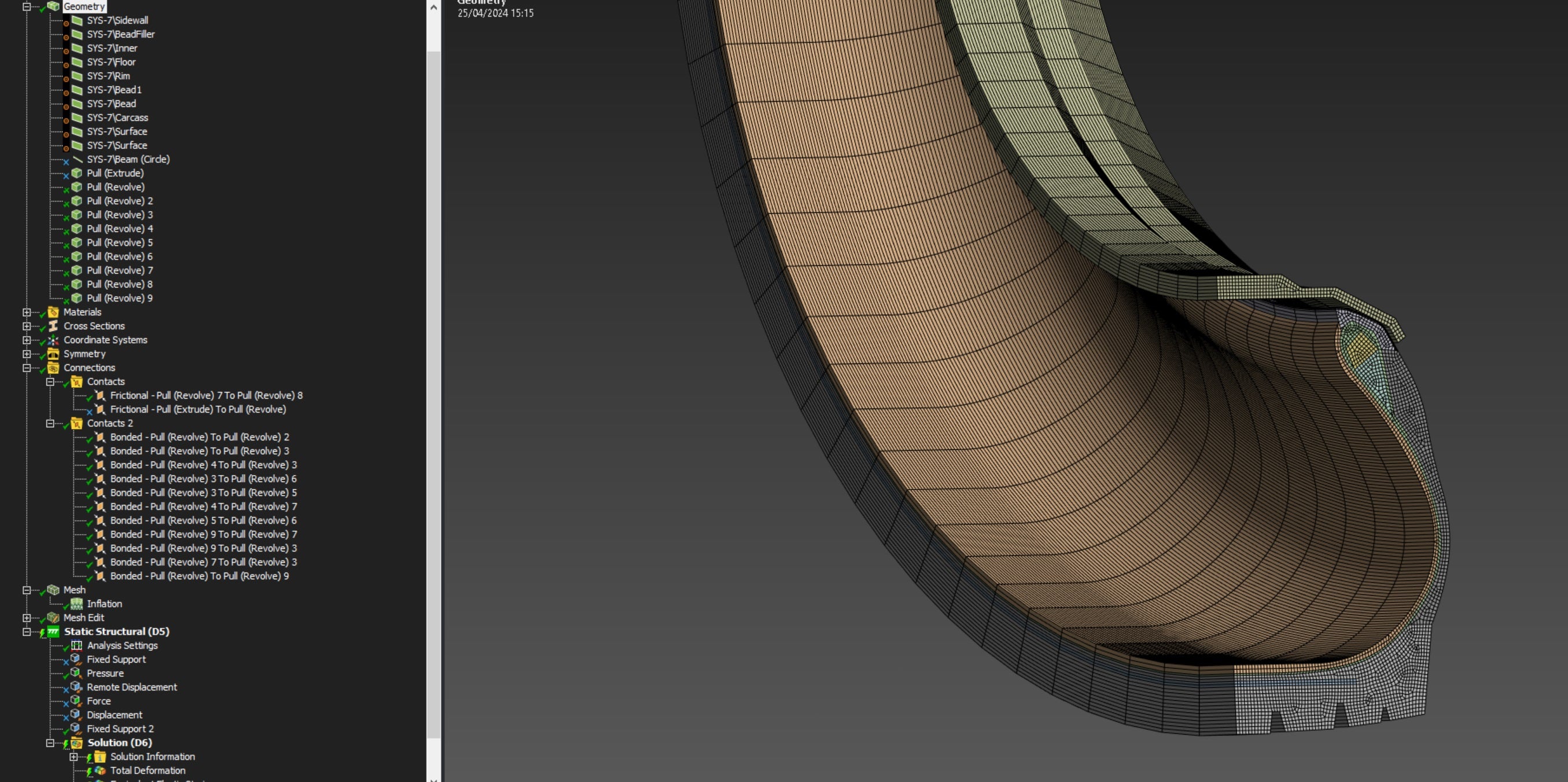

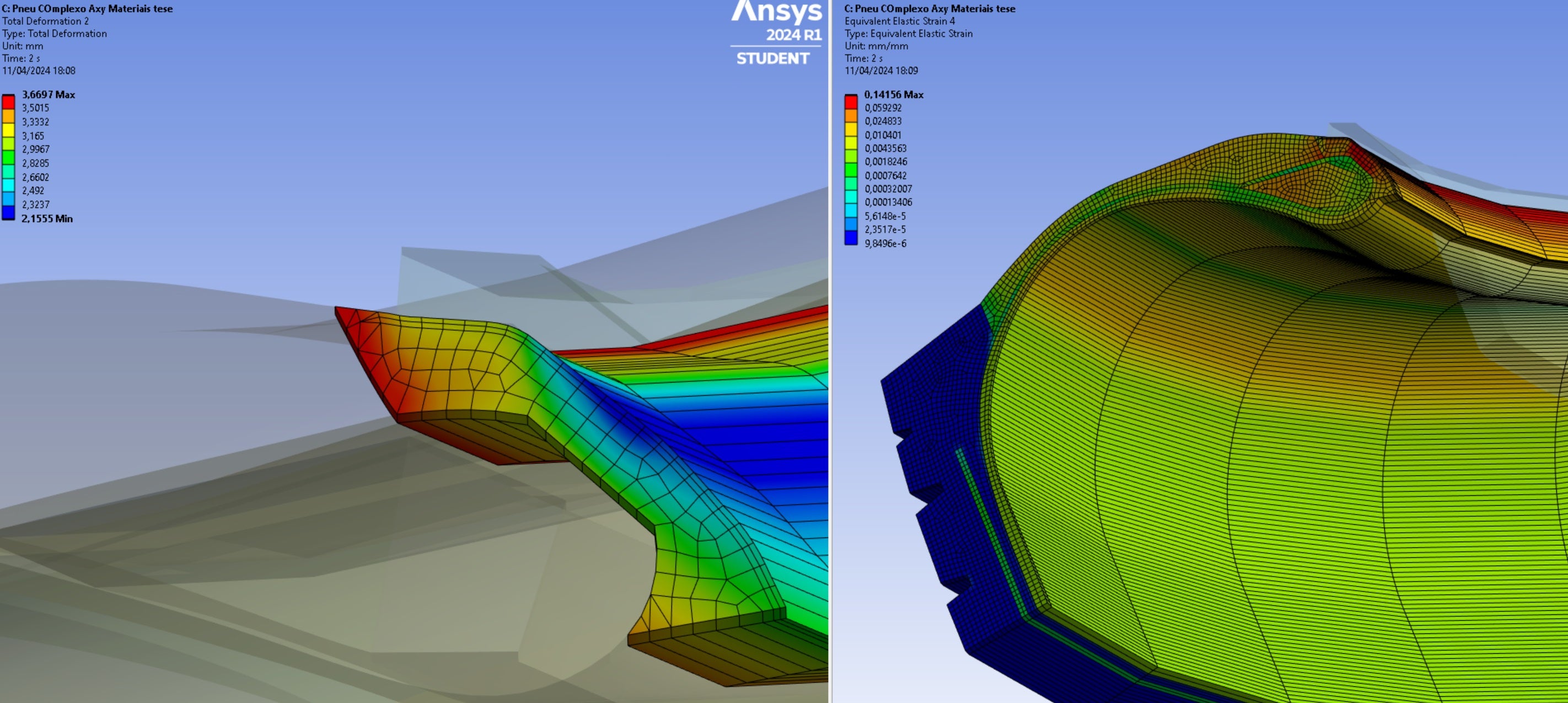

SubscriberHello, I'm modeling a tire in 3D as well as the asphalt and the rim. My tire is subjected to a pressure of 0.22 Mpa but I'm having a lot of problems with the simulation. When I did the same simulation but using an Axyssimetric Model I didn't have any problems but when I move on to 3D I can't get the model to converge.I'm already using Large Deflection because some of the materials are hyperelastic.Can anyone help me? How should i define the contact between tire/rim ? Frictional (0.3) according to literature... Also i´m using two symmetric regions, i only made 180º and the other half is symmetric as well as the other side of the tire cross-section. My objective is to compress the tire aginst the floor and study the resulting defformation... -

April 25, 2024 at 2:52 pm

-

April 25, 2024 at 8:50 pm

peteroznewman

SubscriberThe element shapes have a high aspect ratio which degrades element quality and may impact convergence. Try to sweep more elements around the tire. You can offset the increase in model size by using larger element sizes in the cross-section. Those two changes will reduce the aspect ratio of the elements.

Have you used any Keyopts on the elements that have the hyperelastic material such as the mixed u-P formulation. That is one of several things to change to achieve convergence. This discussion has a list of resources.

-

April 25, 2024 at 9:05 pm

Pedro Miguel Gonçalves

SubscriberThanks for your help, I set the size of the elements to 2mm because if I used a higher value the program wouldn't create a continuous mesh.

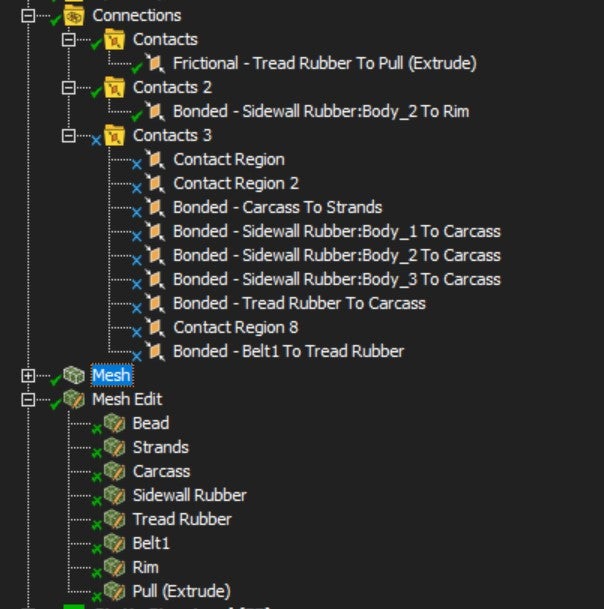

I also had problems with the contacts, because of possible penetrations, should I specify each of the contacts between the different materials that make up the tire as "Bonded" ?What should i change in the u-P formulation ? i don´t know wich type of elements i have ... like 182 181 ect

-

April 25, 2024 at 9:51 pm

peteroznewman

SubscriberPedro, there are many resources in the discussion I linked to above, please review them. For your question on the u-P formulation, this video has more information.

I recommend deleting all the bonded contact in the model and replacing it with Shared Topology in SpaceClaim. Do this on a copy of your model in case you have problems meshing. Do not use Shared Topology between the rim and the tire so that you can use frictional contact there.

-

April 28, 2024 at 12:56 pm

Pedro Miguel Gonçalves

SubscriberThanks againI've looked at what you've sent me and I've changed a few things, regarding the u-P formulation, as I have solid 185 elements I used Keyopt(2)=1 but in the solver it already appears that this command had already been defined and that it wasn't necessary to define it again...I've managed to get the results to converge, but there's one big question that I can't find the answer to. I made the cross-section of the tire and defined "share topollogy" in the space claim between the parts that constitute my tire.When I analyze using axisymmetry, the various parts of my model are connected to each other (because of the shared topollogy), but when I move on to a 3D analysis, using the "Revolve" command and doing it for each of the parts of my tire, I don't know why, I lose the connections I already had.The only way I've found to solve the problem is to manually define each of the contacts as bonded, but this will greatly increase the computational calculation ... is there any way to solve this ??Can you help me? -

April 28, 2024 at 10:18 pm

peteroznewman

SubscriberI have only used Pull to create a 3D mesh from a 2D mesh on a single body part. I don't know what happens when you have a multibody part. Maybe the software is smart enough to share nodes automatically, maybe you have to perform a Mesh Merge. In either case, you won't need bonded contact. If you suppress the Rim and only have the Tire, you can run a Modal analysis and request 12 modes. Don't use any supports in the Modal analysis. You should get a practically zero frequency for the first 6 modes, then a large jump up in frequency at mode 7. This will be evidence that all the bodies in the tire are connected. You can examine the deformed shape animations for modes 7 - 12 to convince yourself that they are working.

-

May 15, 2024 at 11:39 am

Pedro Miguel Gonçalves

SubscriberHi Peter, just to tell you that I managed to make the PULL-Revolve command properly, it just requires that the connections between the several parts have already been defined in Space Claim or (cad) before applying the revolve command and everything works ok.

But I´m still having problems with the simulation, i have started a new discussion about it, 3D tire Static Structural...

Thanks for all the support :)

-

- The topic ‘3D Tire Modeling using Ansys Mechanical Static Structural – Help !!’ is closed to new replies.

-

4979

-

1650

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.