TAGGED: 2d-domain, ansys, divergence, fluent, meshing-speed

-

-

August 22, 2021 at 10:02 pm

KSD

Subscriber@Rob Sir, actually some of the questions were discussed previously in the post

(/forum/discussion/comment/129271#Comment_129271)

but that post already contain lot of comments related to other doubts, due to which now it has become difficult to explain my current doubt clearly in that old post.

That's why I have created a new post just to focus on my current doubt.

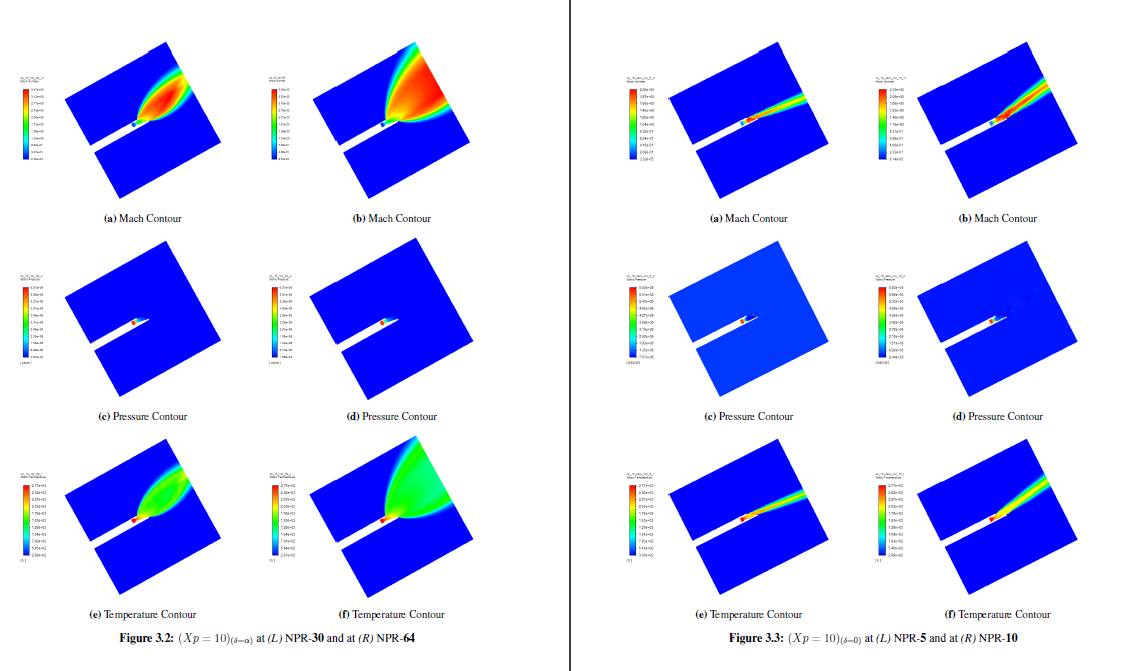

Sir, I have first created a mesh for supersonic analysis, where my solution was diverging despite of having good quality mesh and also I have considered that cell variation is not high at all. The video of the meshing quality examination is shown below

August 23, 2021 at 11:19 amRob

Forum ModeratorPost an image of the mesh settings, but also compare the sizing you've used with the domain scale. It's very easy to set sizes which return either an impossible mesh (conflicting local sizing) or an excessive number of elements (sub mm sizing on a km size domain).

August 23, 2021 at 12:17 pmKSD

SubscriberSir, I think I have taken care of the dimensions from start till end. I will attach the images as well

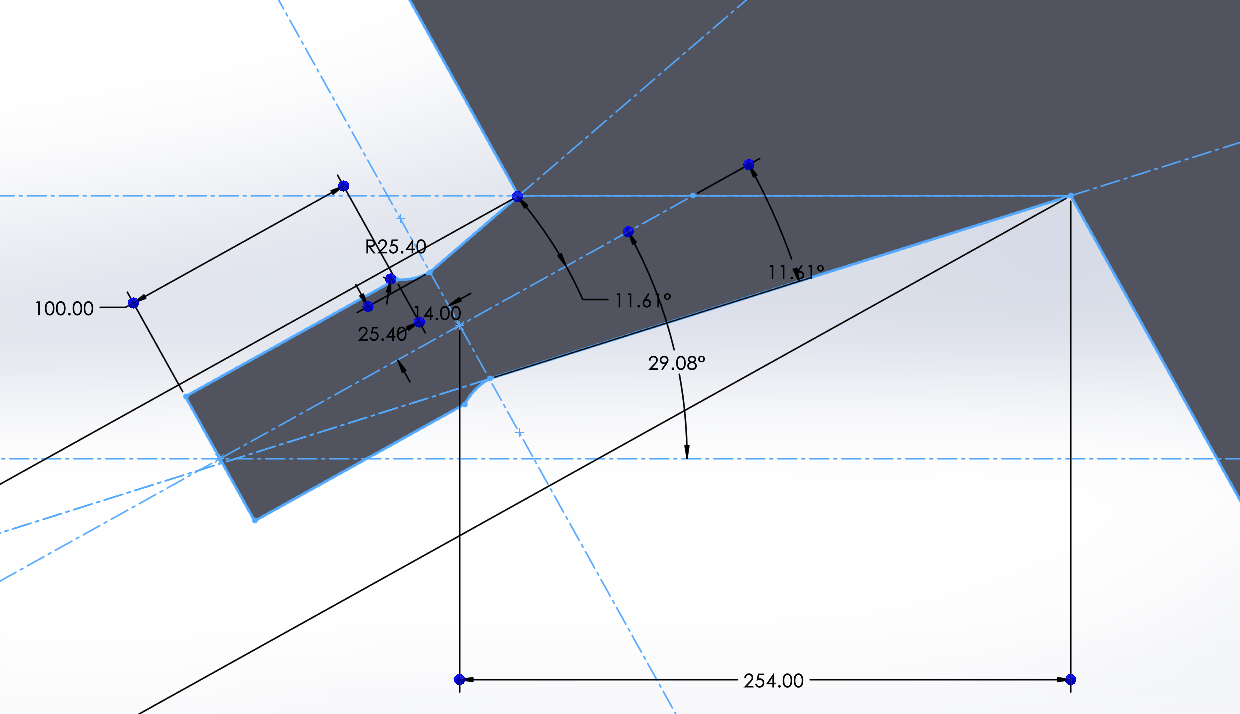

I have given the domain dimension around 15000 X 12000 mm (Height X Width) and also the units are set to millimeters.

The close up view of truncated nozzle all dimensions are in millimeters.

The close up view of truncated nozzle all dimensions are in millimeters.

Even in mesh settings I have ensure that units are in millimeters and the image below shows the global mesh settings where I changed parameters to

Even in mesh settings I have ensure that units are in millimeters and the image below shows the global mesh settings where I changed parameters to

Global Element Size to 5mm

Transition to Slow

Smoothening to High

Number of CPU for parallel to 48 (I have also tried default number of CPU as well but there also it doesn't make any mesh it just shows 5% Meshing. )

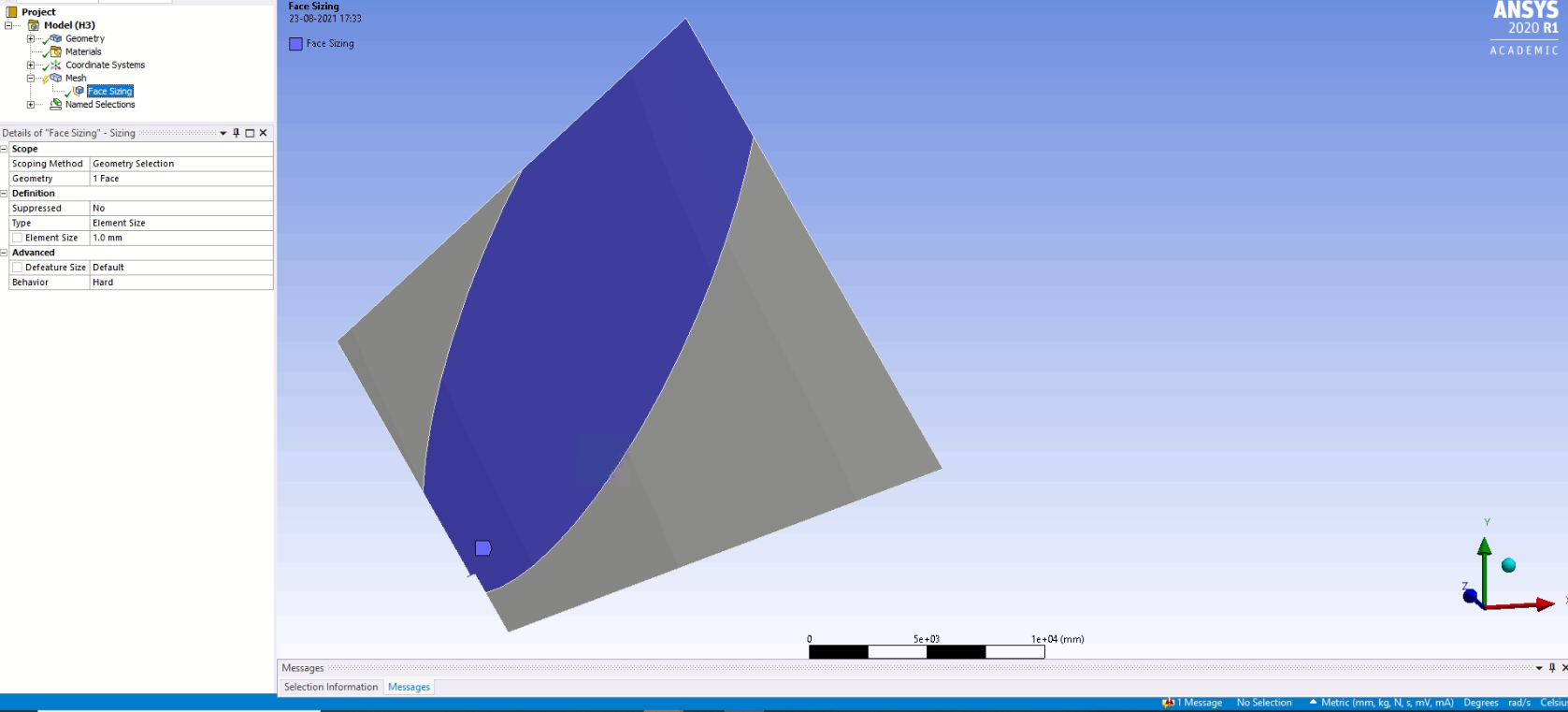

Then I gave local face sizing of 1mm specifically for the jet region of the domain in order to ensure the cell area variation is not high across the jet region.

Then I gave local face sizing of 1mm specifically for the jet region of the domain in order to ensure the cell area variation is not high across the jet region.

And the 1 message which you can see at bottom is not a warning or an issue because I stopped the meshing process after 1 day, I will attach that image as well. Which confirms that there is no issue of less memory available.

And the 1 message which you can see at bottom is not a warning or an issue because I stopped the meshing process after 1 day, I will attach that image as well. Which confirms that there is no issue of less memory available.

August 23, 2021 at 12:53 pmRob

Forum ModeratorLook at the ruler in the Mesher image. Then do a rough hand calculation based on what the Meshing tool thinks the surface area is and how many mm2 cells will fit into that area.

August 23, 2021 at 1:37 pmKSD

SubscriberSir, I got what you are trying to say, the surface area of the leaf shaped split part of domain alone is 1.93 e^8 mm2 and if I give face meshing of 1mm then it will be approx 193 million cells for hex type mesh. It was a great insight that I was blindly giving the local sizing dimension.

I understand now it very clearly that it is a huge number.

Even If I give 2mm face sizing then for leaf part alone it will be close to 48 million cells.

So I think I should give face sizing of 3mm as it will lead to 21 million cells and also considering the whole domain, the total cells should be less than 63 millions as outside leaf shaped part, local sizing is of 5mm.

So if I go with 63 million cells it should take around 1hour or at most 4 hours considering that one your intern student is able to create 20 million cells mesh in 20-40 minutes.

Ok Sir, I will try that hoping for the best.

August 23, 2021 at 1:51 pmRob

Forum ModeratorLook at the domain scale: just because you created the CAD in mm doesn't mean it was translated in mm. Note, the Student cell count is limited at 512k cells, and we were using Fluent Meshing and not Ansys (Workbench) Meshing.

August 23, 2021 at 2:00 pmKSD

SubscriberSir, I would check that whether the mesh has been transferred properly or not, and I have created mesh with million cells, but I think there is no such limitation for academic research license version of Ansys. Or are there any limitation?

Yeah definitely I am not using the free student version of Ansys.

Or Sir are you saying even 63 million cells also too large in workbench meshing?

Should I increase the face sizing greater than 3mm ? I think to capture shocks we need small cell size.

August 23, 2021 at 4:17 pmRob

Forum ModeratorResearch doesn't have a cell limit, but you do need HPC to run big models.

Re the cell size: you will need a fine mesh in the nozzle and to capture the shocks. You won't need such a fine mesh elsewhere. 63M cells in 2d may cause problems with facet ID storage, but I have no idea if it's not going to work.

October 19, 2021 at 4:57 pmOctober 20, 2021 at 10:31 amRob

Forum ModeratorYou're welcome.

Viewing 9 reply threads- The topic ‘2D Meshing Speed Issue / Not showing any progress in meshing even after many hours’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4618

-

1530

-

1386

-

1209

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.