-

-

April 29, 2022 at 3:45 am

ali_elsharkawy

SubscriberApril 29, 2022 at 7:31 pmSean Harvey

Ansys Employee

Based on what you shared, you have auto time stepping as program controlled. For this type of large deformation, large strain it won't be ideal. Change to on, then set the initial, min and max substeps to break up the loading into smaller substeps. In this type of rolling simulation, you won't want more than a few degrees per substep, so set your initial substep so that over the time for that step, you are not rotating more than 1 or 2 degrees. Then for max substeps, set it even large if the solver needs to bisect, which it will. Don't be afraid to set the max substeps 10x higher than initial for this case. The min substeps gives you control so you get at least so many substeps which helps with smooth results reporting, etc.

Also, be sure your contacts are set properly to frictional with a realistic coefficient of friction.

See if this helps you get further.

Thanks!

Sean

April 29, 2022 at 8:15 pmali_elsharkawy

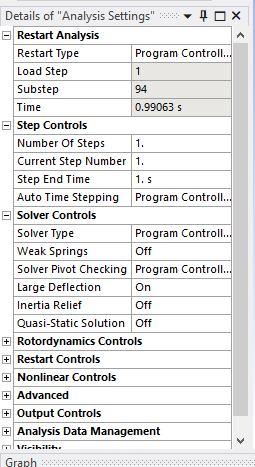

Subscriber, the problem is I do not have control over sub-steps

it is either automatic control or manually, in manually I have two options:

values program defined

set to initial

April 29, 2022 at 8:34 pmApril 29, 2022 at 9:14 pmSean Harvey

Ansys Employee

So right now you are trying to restart the simulation. You want to right click on the solution branch and clear the generated data. Then you will be starting a new simulation, not a restart. Please try that.

Regards Sean

April 29, 2022 at 9:44 pmApril 29, 2022 at 9:56 pmSean Harvey

Ansys EmployeeThat is progress! This is a nonlinear simulation. It will take some effort to get a viable solution. You are using 1 element in the thickness direction of your sheet. Unless this is a solid shell element, it won't capture the plasticity. You should set a mesh size to give at least 4 to 6 elements (as a start) in the thickness and keep your aspect ratios from being excessive.

You should check out these courses on plasticity which will help.

Convergence Problems in Metal Plasticity | Ansys Courses

Metal Plasticity | Ansys Innovation Courses

In this last course in the simulation examples, there is a cold rolling problem that is very similar.

Best of luck and let us know after looking at this content if you are stuck.

Regards Sean

April 29, 2022 at 10:36 pmApril 30, 2022 at 1:33 amSean Harvey

Ansys Employee

You should have two contact bodies. In the details set behavior to asymmetric. Then make sure the workpiece has the contact surface and the roller has the target. Do this for both contacts. What do you have for initial, min, max substeps? How much rotation is specified on the rollers?

Thanks

Sean

April 30, 2022 at 10:40 pmali_elsharkawy

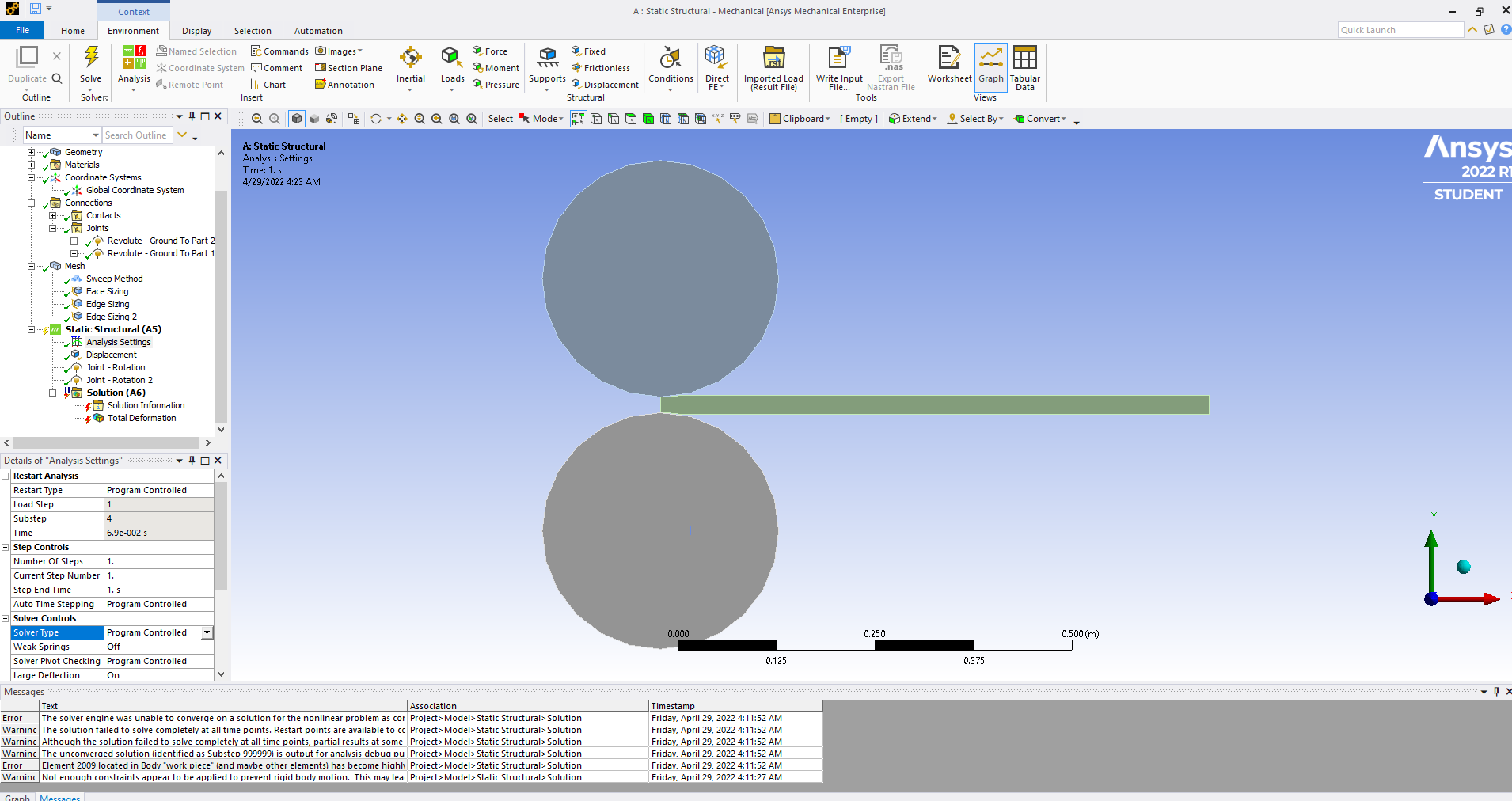

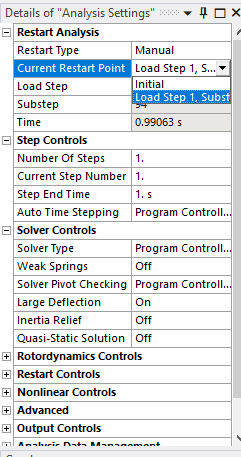

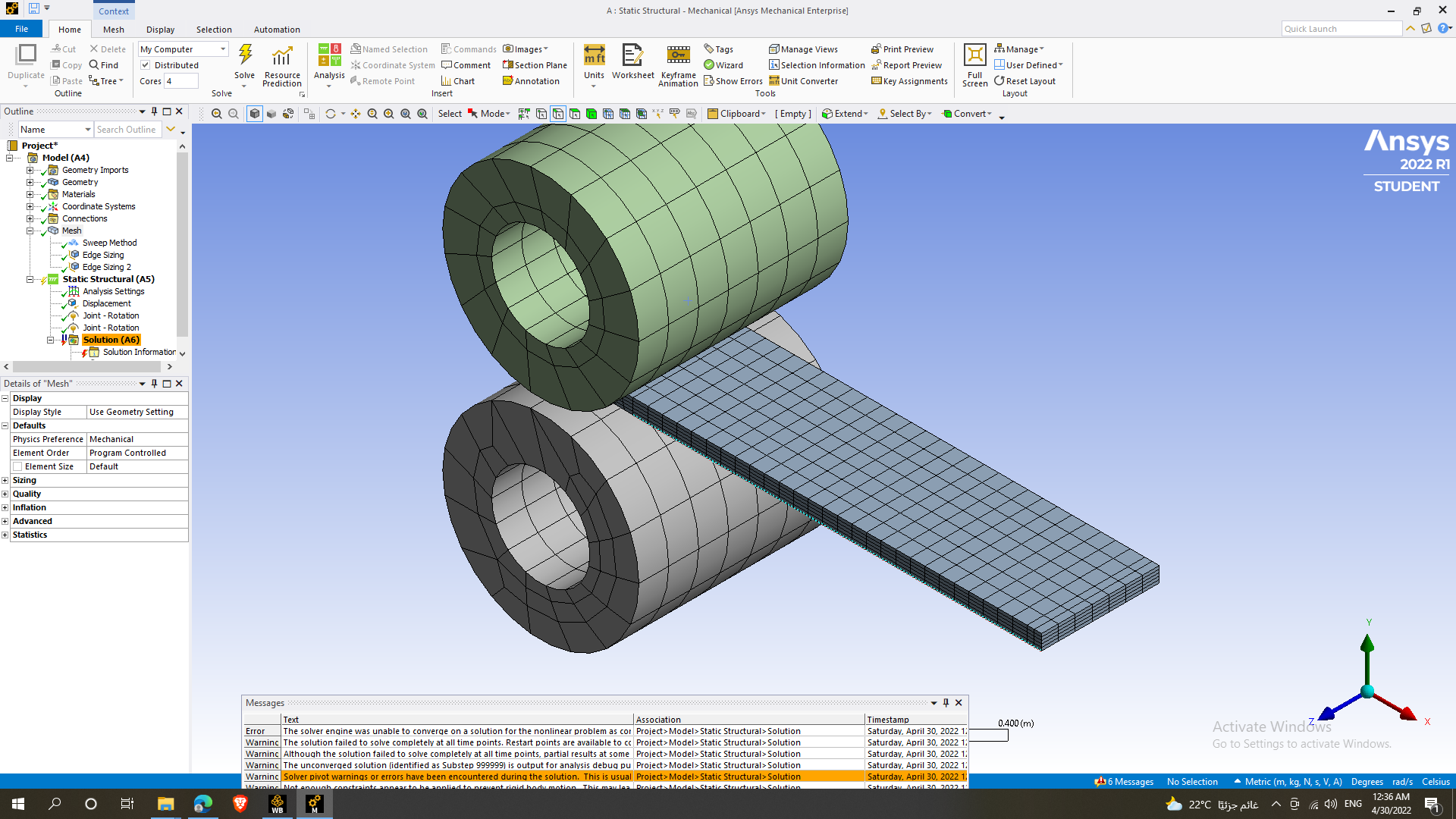

Subscriberso sorry for being late I had some problems, so I redesigned the model and set the behavior to asymmetric and the rollers to rigid bodies with initial and minimum substeps of 300 and maximum of 750 and I got the same problem: The solver engine was unable to converge on a solution for the nonlinear problem as constrained.Please see the Troubleshooting section of the Help System for more information.

and got this new one :

Large deformation effects are active which may have invalidated some of your applied supports such as displacement, cylindrical, frictionless, or compression only.Refer to Troubleshooting in the Help System for more details.

when turning large deflection off and trying to solve there are no errors but the roller rotates as it eats the material :((

May 1, 2022 at 1:32 amMay 2, 2022 at 1:43 amSean Harvey

Ansys Employee

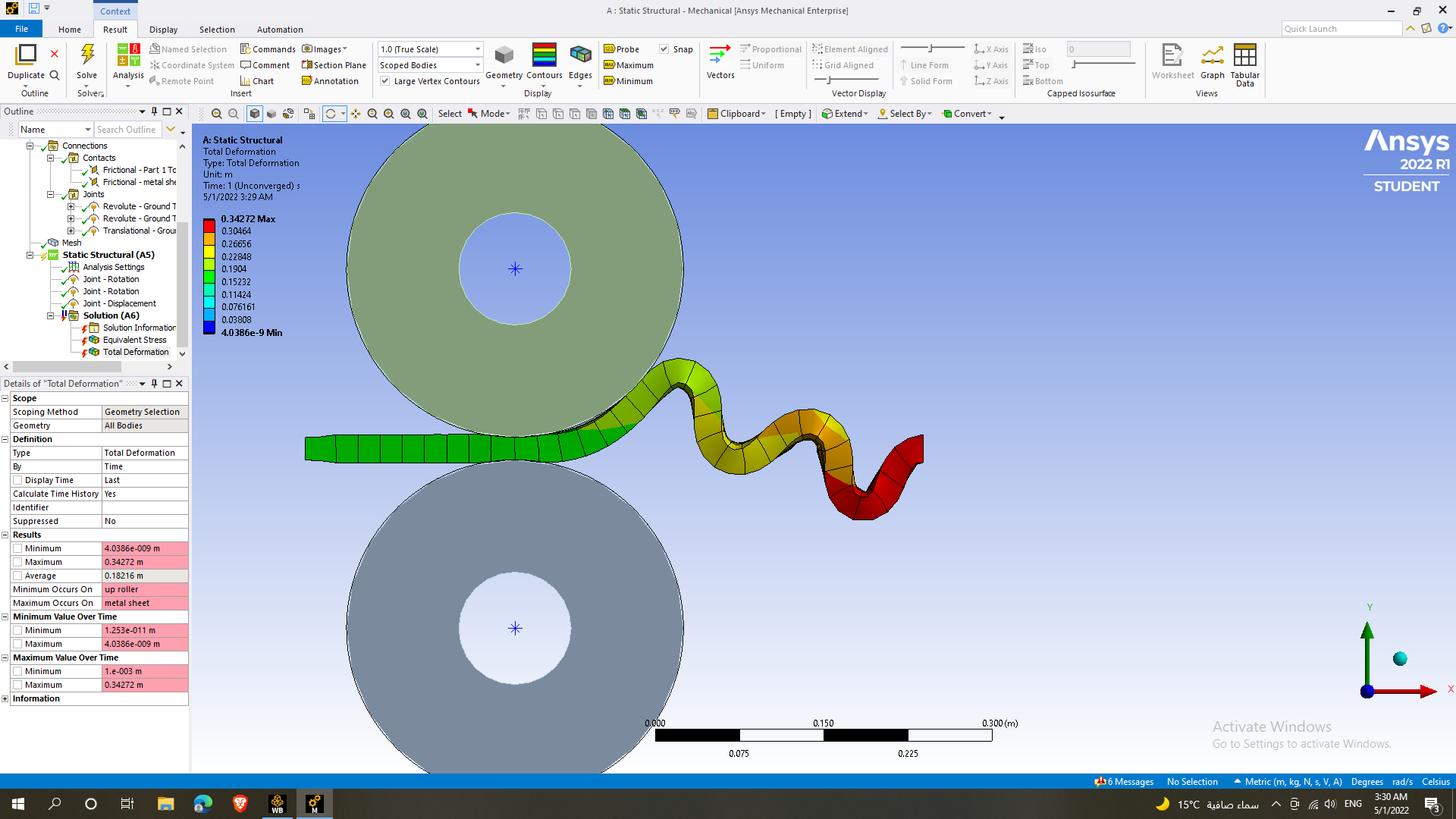

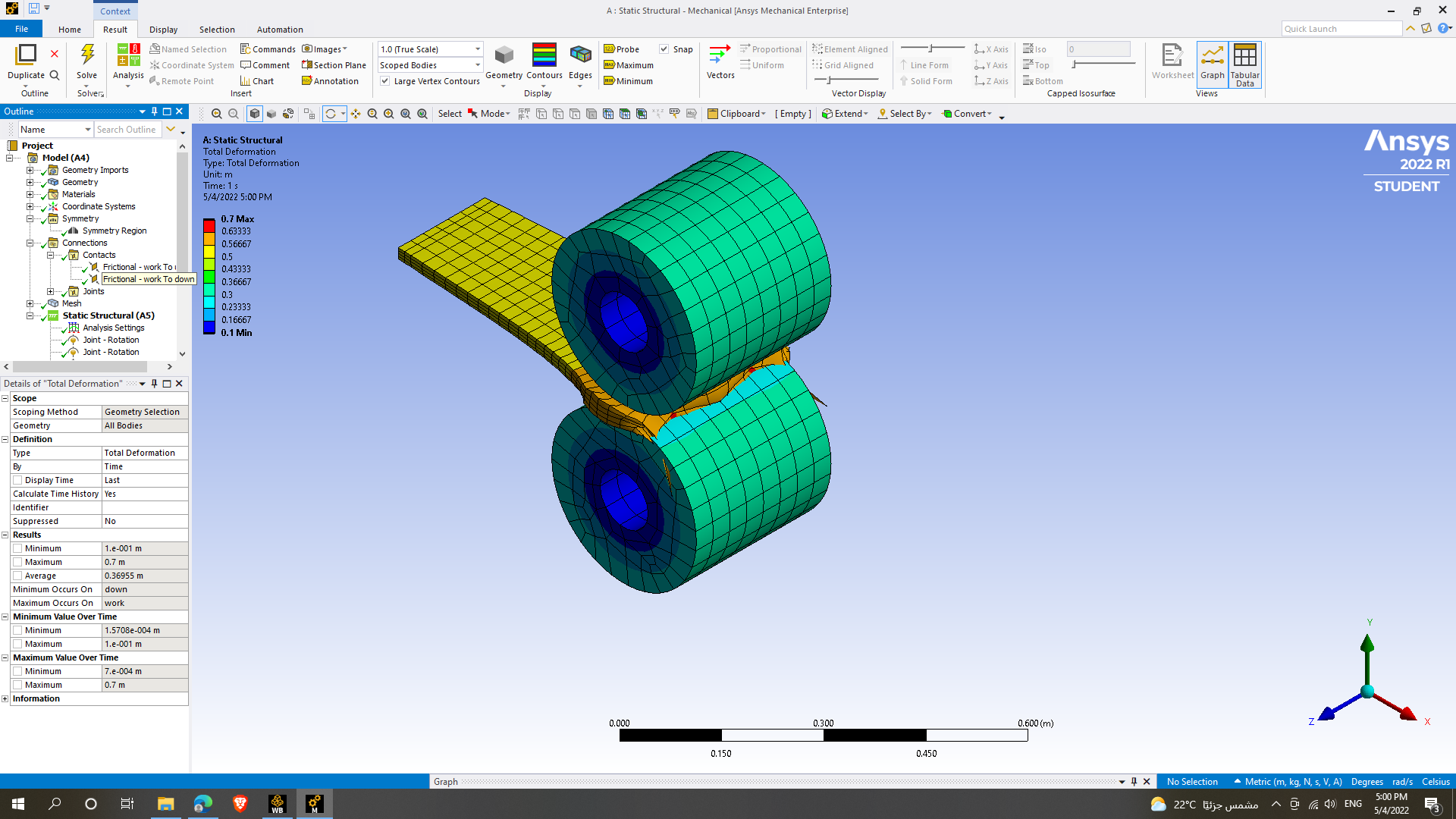

You will need large deflection on. This is not a small deflection problem. The latest images you show only have 1 element in thickness direction.

One suggestion that can help is to run the model as 1/2 symmetric. We can assume that the rolling process will affect the sheet equally in +y as -y, provided we ignore effects like gravity which are likely small.

You cut the sheet in the xz plane and model only the +y or -y region. At the symmetry plane, you can apply a frictionless support which will not allow the nodes to more on that plane in y direction, but they can move in x and z. This will help to stabilize the problem. Also, since you are using student version, you can now put a finer mesh in the x and z directions and not hit the node limit of the free student version. You still will want maybe 2 to 4 elements in thickness direction to capture the plasticity, but this does not mean you won't need more. That would come from performing a mesh convergence study.

One other option is to go to the behavior on the roller, and change it to rigid. Then you can scope the joint or remote displacement to the inside of the roller to impart the rotational motion. You can make the mesh on the roller a bit finer too. When we make the body rigid, Mechanical meshes the contact surface, but does not mesh the body since we have told it to use a rigid behavior. This assumption is good when we don't expect deformations in the tooling. I don't know if this assumption is valid for you model, but in many rollering problems, where the workpiece has a lower yield than the tooling it is.

Please try these suggestions.

Best of luck!

Regards Sean

May 2, 2022 at 6:05 amali_elsharkawy

SubscriberHi, MR first of all I want to thank you very much for helping me you really helped me to understand very much :)

second, I still facing a problem

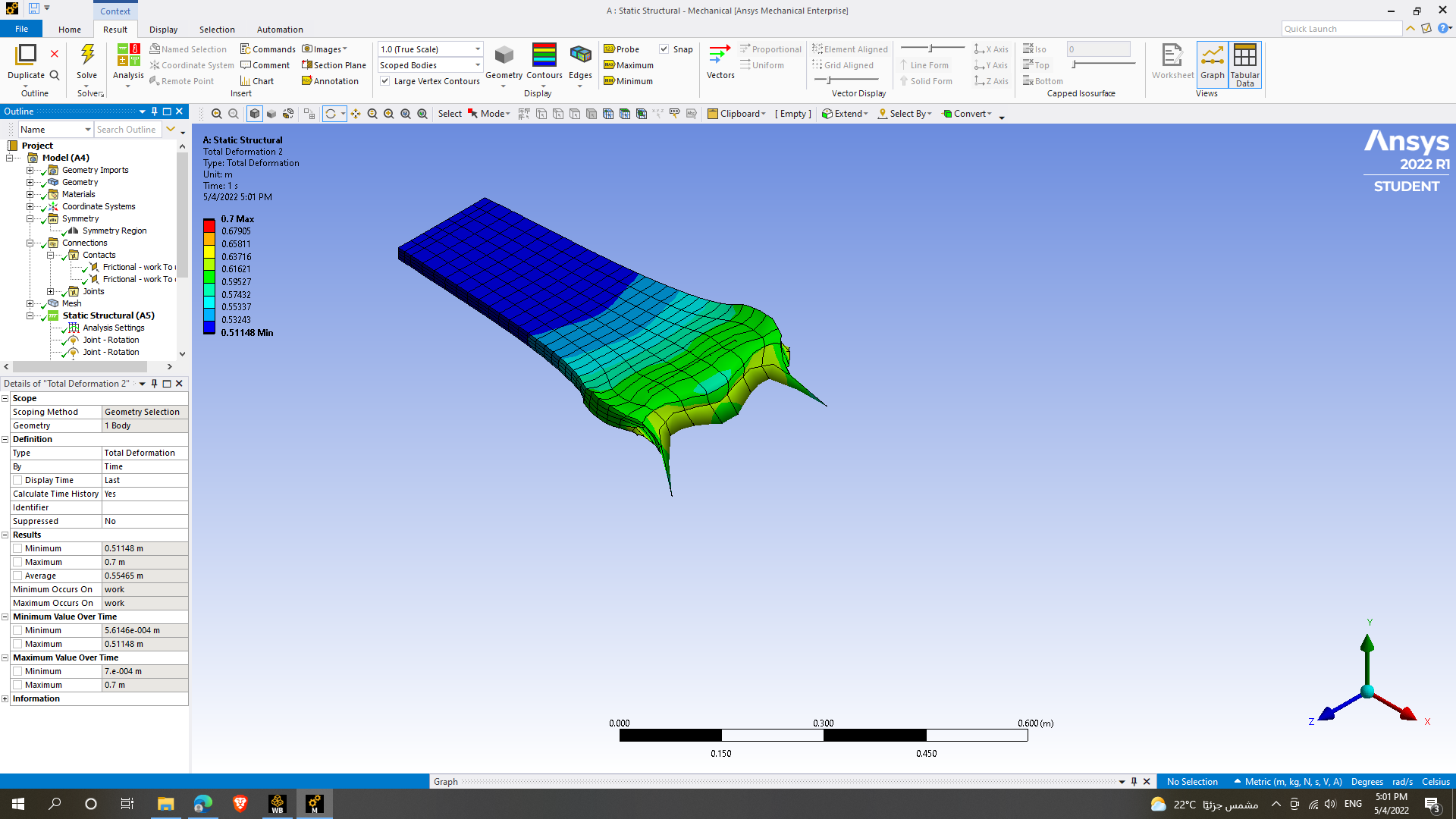

in the deformation, the sheet is still not deformed it is deformed when it is between the rollers only then in the exit the sheet return as the initial height

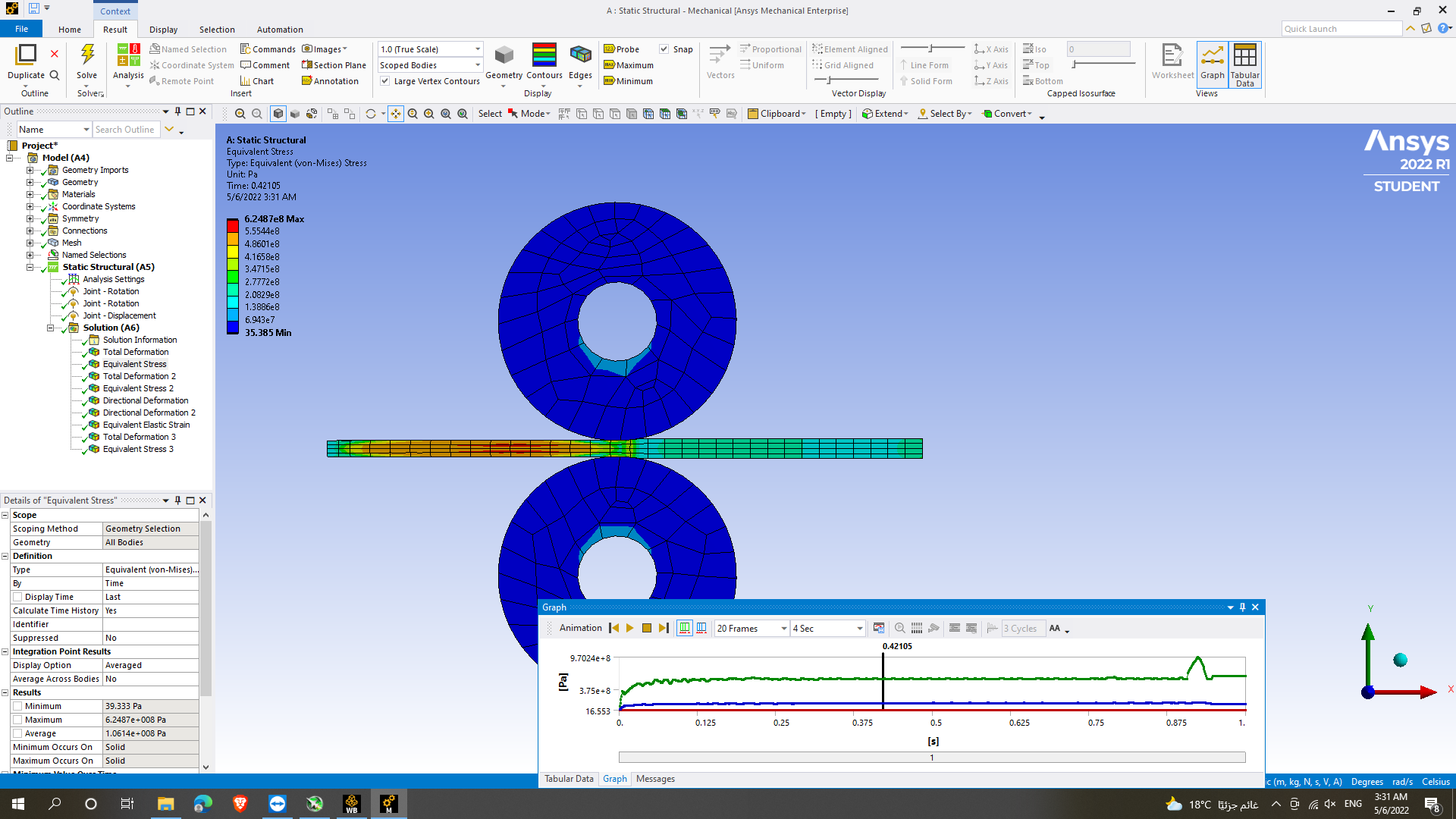

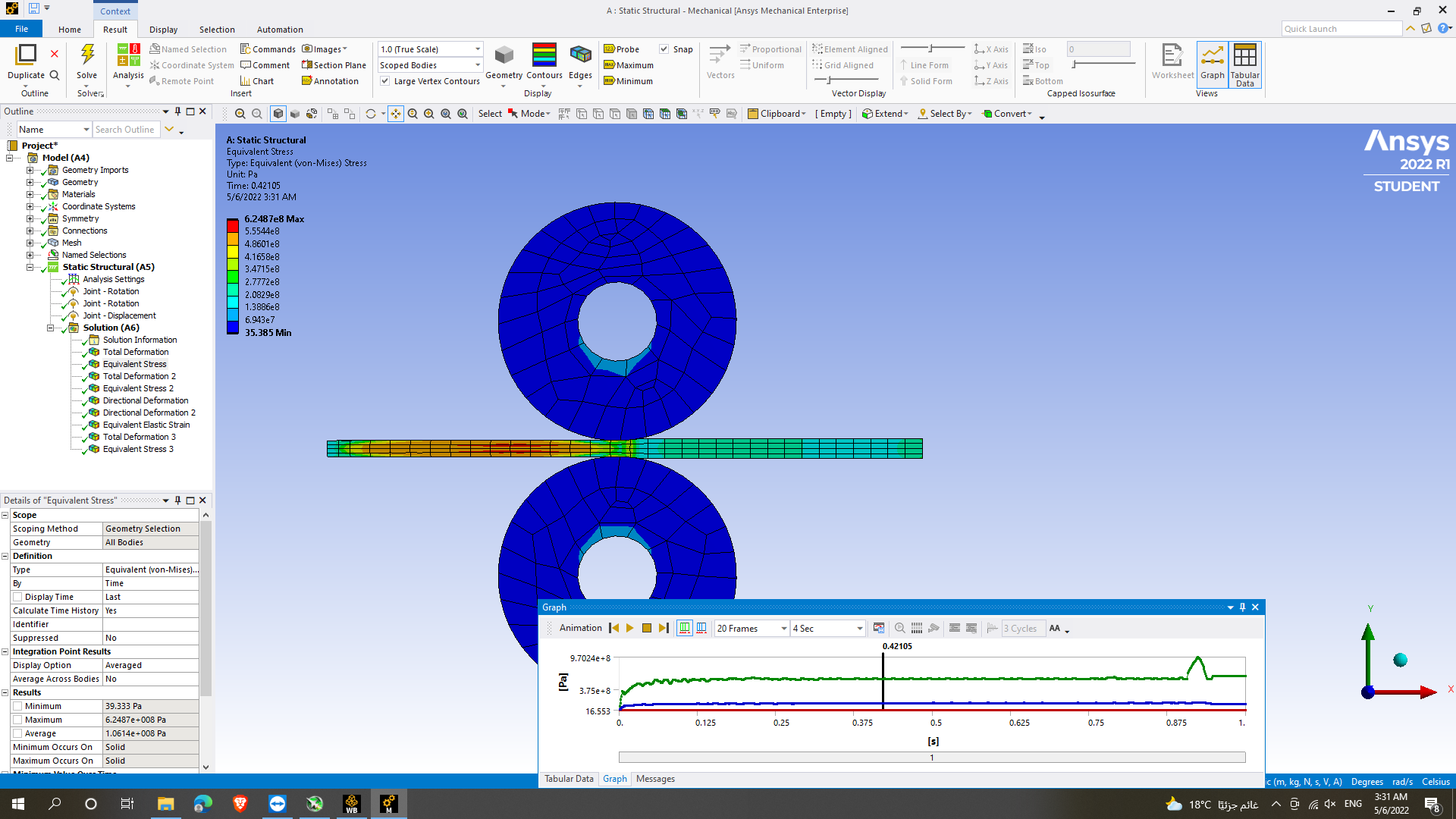

May 2, 2022 at 6:09 amMay 2, 2022 at 9:10 amali_elsharkawy

SubscriberAnd when I change roller to flixable bodies to calculate the total stresses over then there is no change of thickness even in the thickness between the rollers

May 2, 2022 at 4:51 pmSean Harvey

Ansys Employee

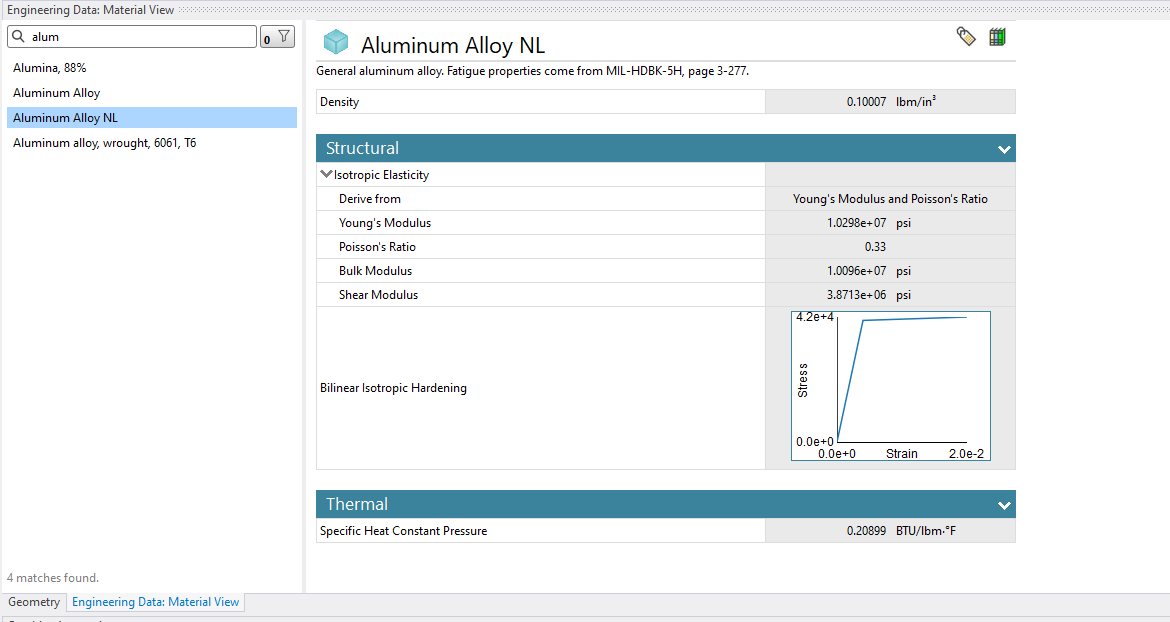

You are welcome. So, for your material, have you included a plasticity material model in engineering data? You will want to post-process plastic strain to give an indication of how much plastic straining is taking place. Also, your mesh density in the x-direction is way too coarse. You need to make the at least 4 to 8 times finer in-plane (x-z).

Regards Sean

May 3, 2022 at 3:03 amMay 3, 2022 at 4:57 amMay 3, 2022 at 5:08 amMay 4, 2022 at 3:02 pmMay 4, 2022 at 4:01 pmpeteroznewman

SubscriberRollers should always be wider than the material being rolled.

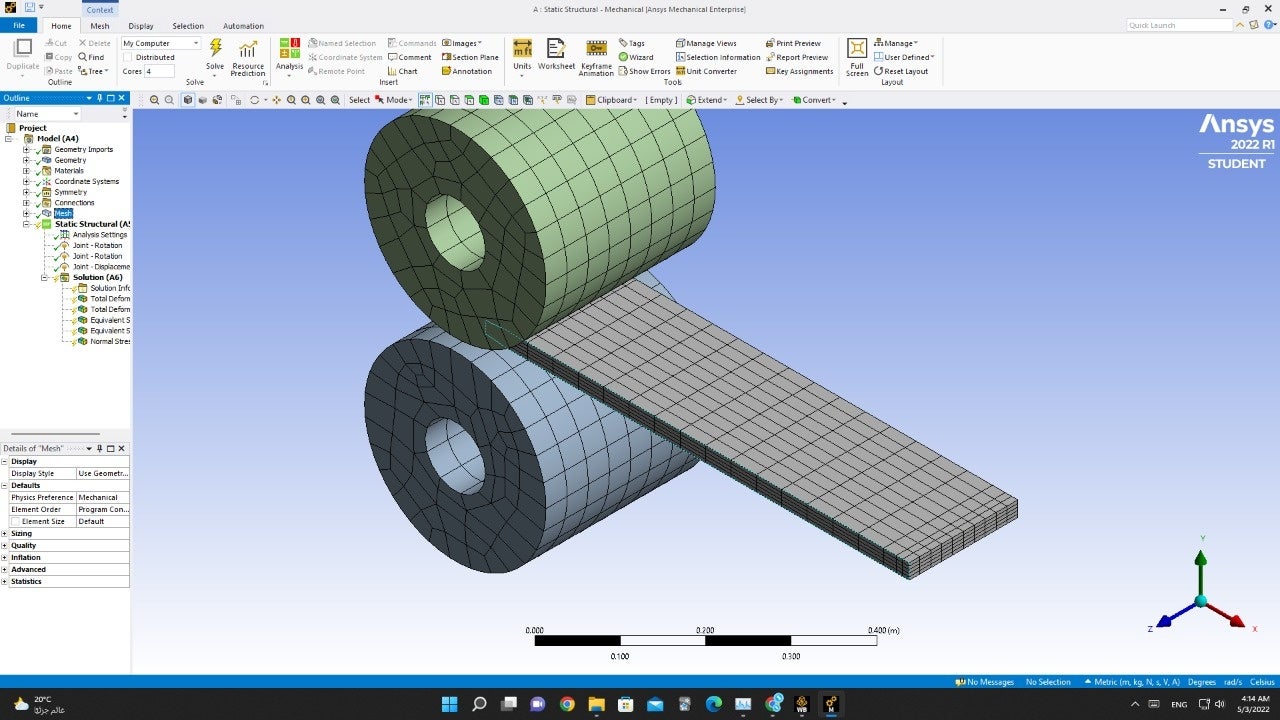

You should take advantage of Symmetry. already mentioned 1/2 symmetry using a plane at half the thickness of the material and using a single roller. I suggest 1/4 symmetry by adding a plane at half the length of the roller so the material is only half as wide.

May 4, 2022 at 5:41 pmSean Harvey

Ansys Employee

What notes is a great suggestion as I had indicated on symmetry. I had not indicated that the roller should be wider. Thanks Peter.

Your mesh is still too coarse on the plate, so consider going even finer.

Regards Sean

May 4, 2022 at 9:56 pmali_elsharkawy

Subscriberthe thickness of the roller is 280 and the thickness of metal sheet is 180 it doesn't make sense that elongation in z- direction be that value

May 4, 2022 at 9:58 pmali_elsharkawy

SubscriberAnd also Ôêålength is too small and it doesn't make sense either

May 4, 2022 at 10:03 pmpeteroznewman

SubscriberDon't pay attention to results from models that are not behaving well.

Update the model using the 1/4 symmetry then we can talk.

It's also important to take small steps, so both the Initial and the Minimum Substeps should be large numbers (or the Time Increment should be small if using Time).

May 4, 2022 at 11:44 pmali_elsharkawy

SubscriberCan you help me understanding how to add plane of symmetry

I did it before but by choosing a surface and add system region using the normal direction as the symmetry normal

Is that the way it should be or there is other feature I don't know about it

Sory for bothering

May 4, 2022 at 11:57 pmali_elsharkawy

SubscriberMay 5, 2022 at 12:20 ampeteroznewman

SubscriberIn SpaceClaim (or DesignModeler) insert a Plane and cut the geometry in 1/2 and delete 1/2 the solids. Repeat with another plane.

In Mechanical, insert a Symmetry folder and insert under that a Symmetry Region and select all the cut faces for one of the planes and set the Coordinate Axis that has the Normal vector to that plane. Repeat for the other plane.

Instead of using Symmetry, you can just select all the cut faces and Insert a Displacement and set the normal to 0 leaving the other two Free. Repeat for the other cut plane. This is exactly the same as using Symmetry.

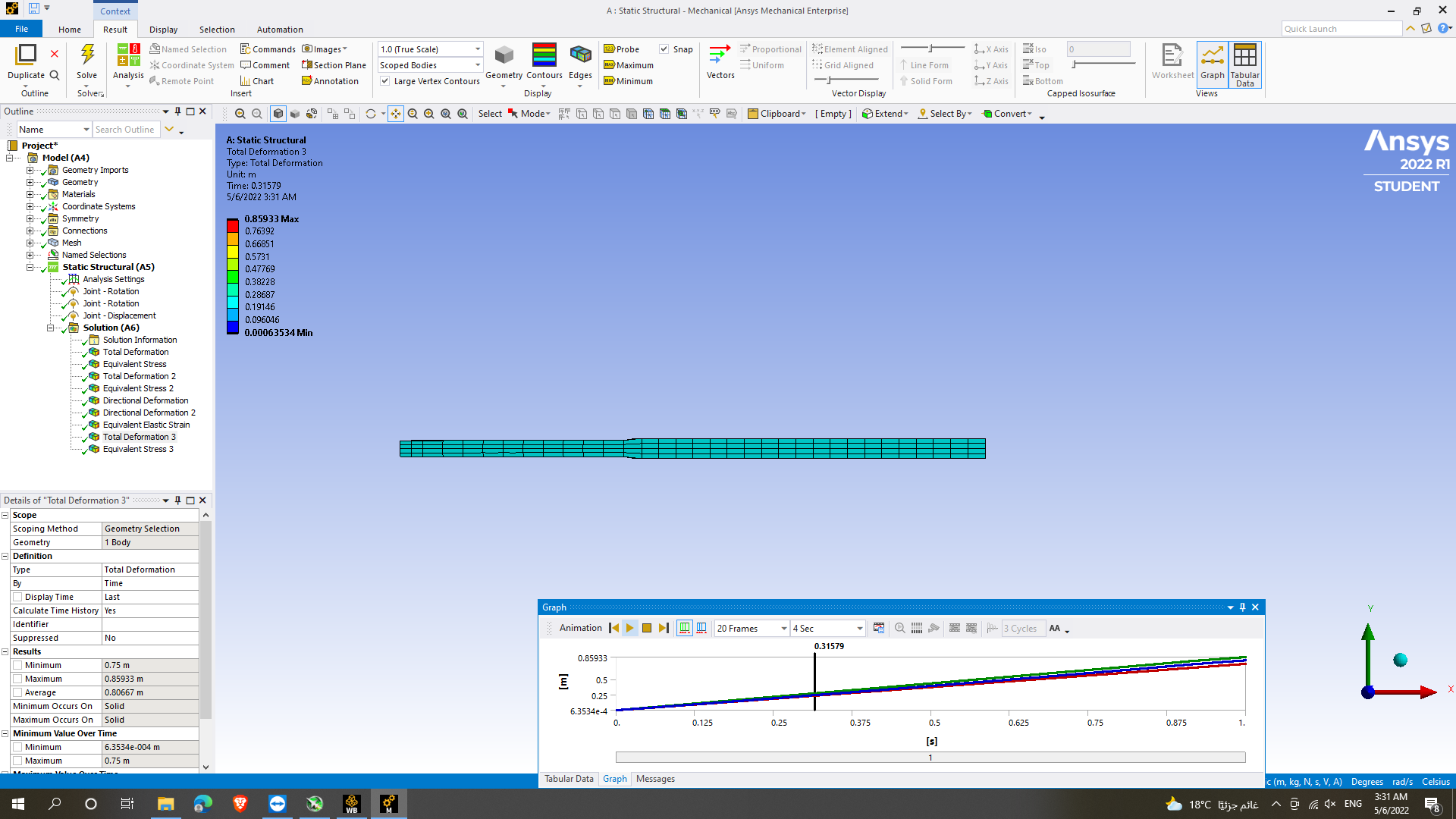

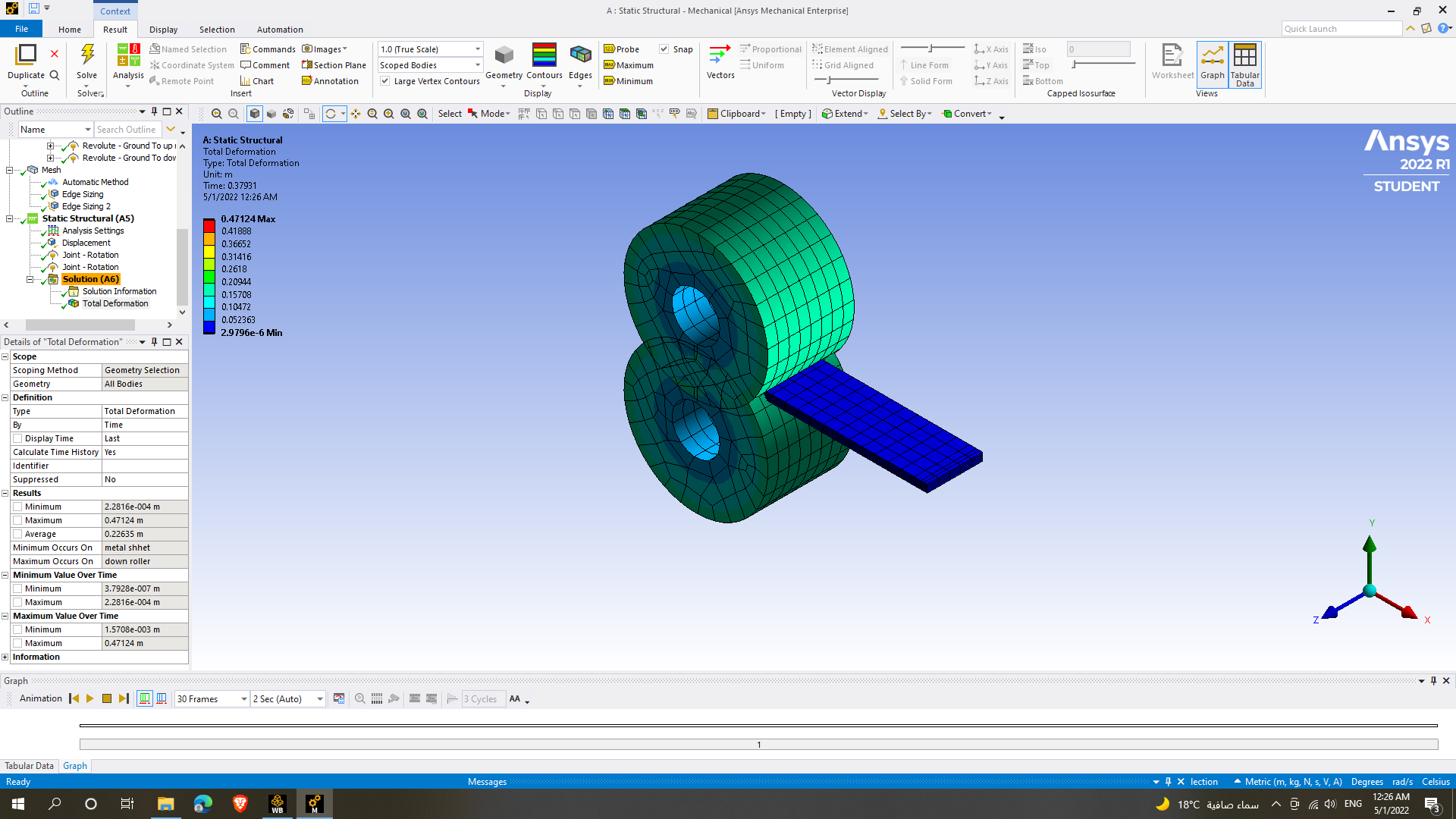

May 5, 2022 at 12:59 amali_elsharkawy

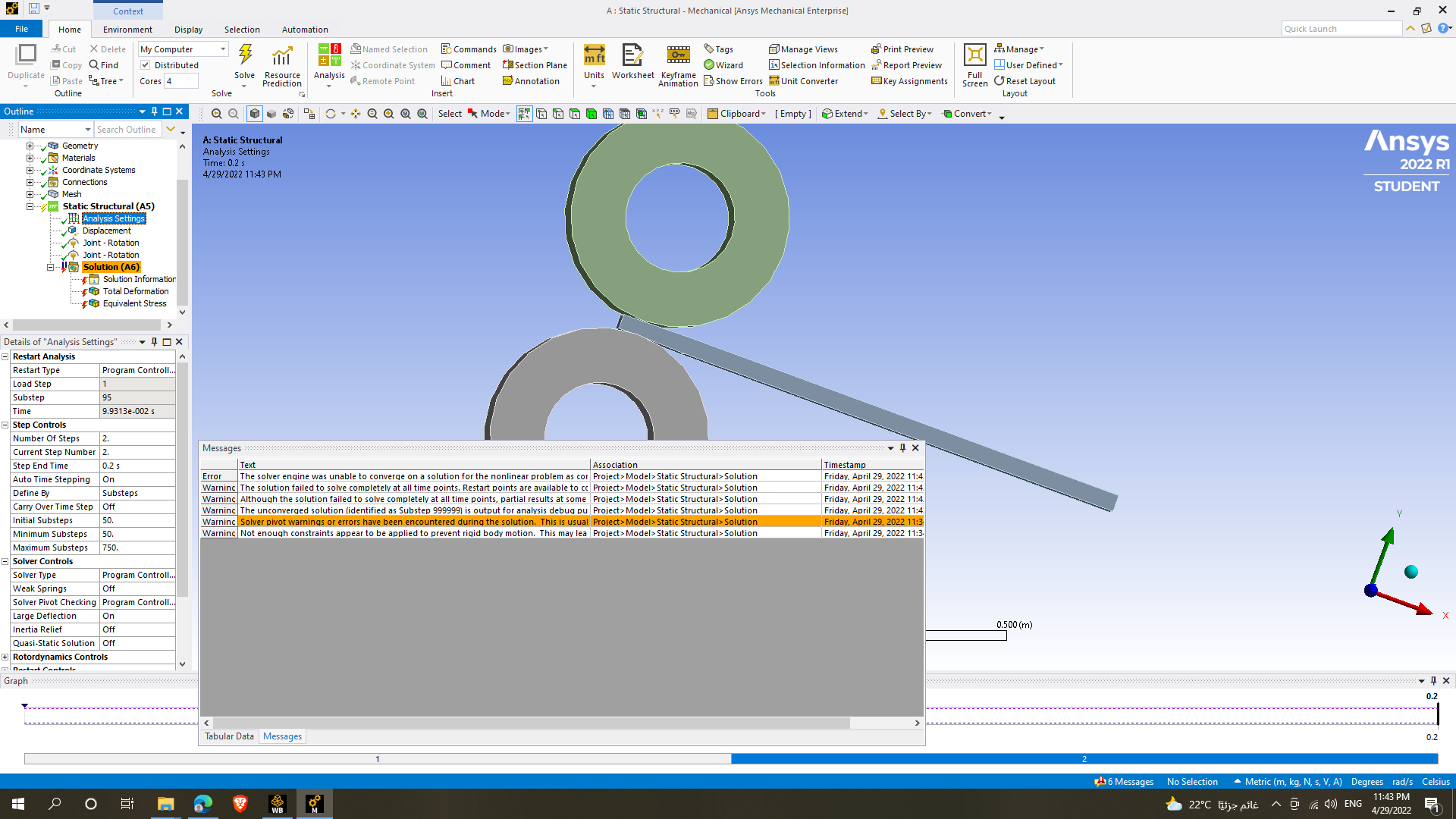

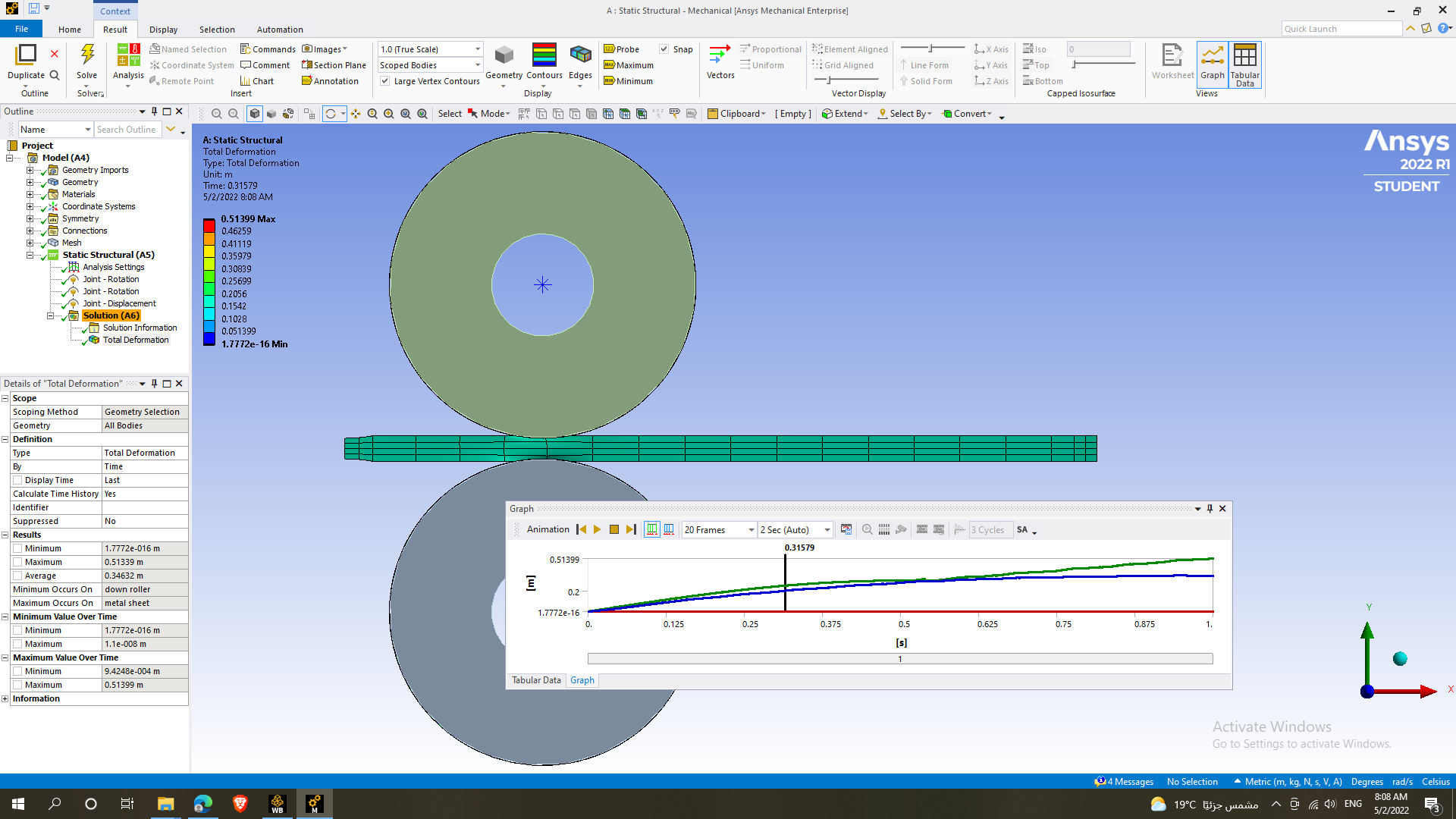

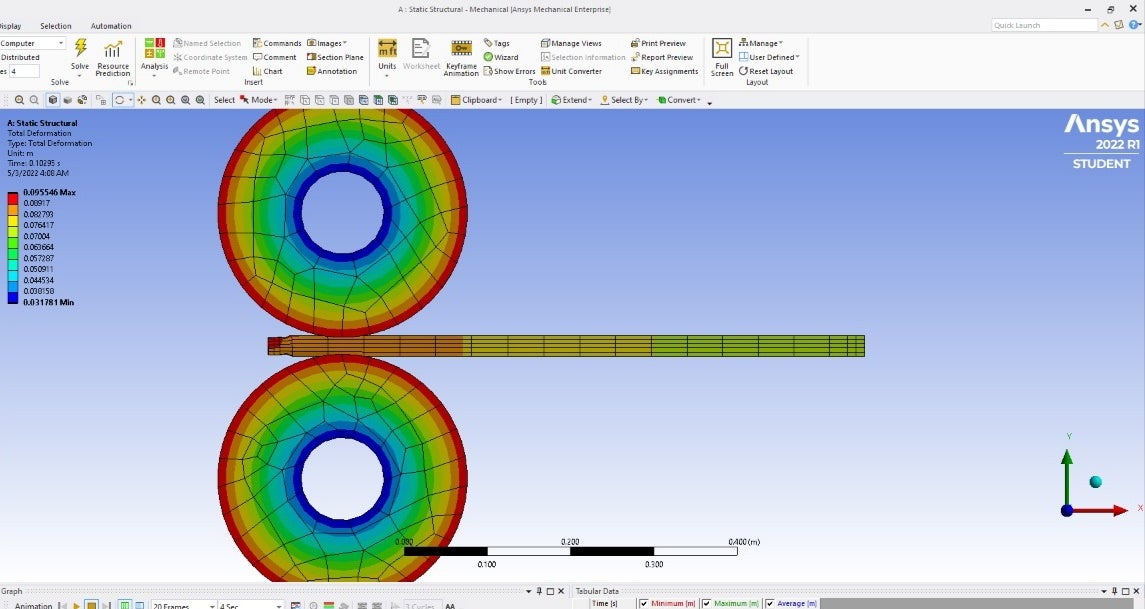

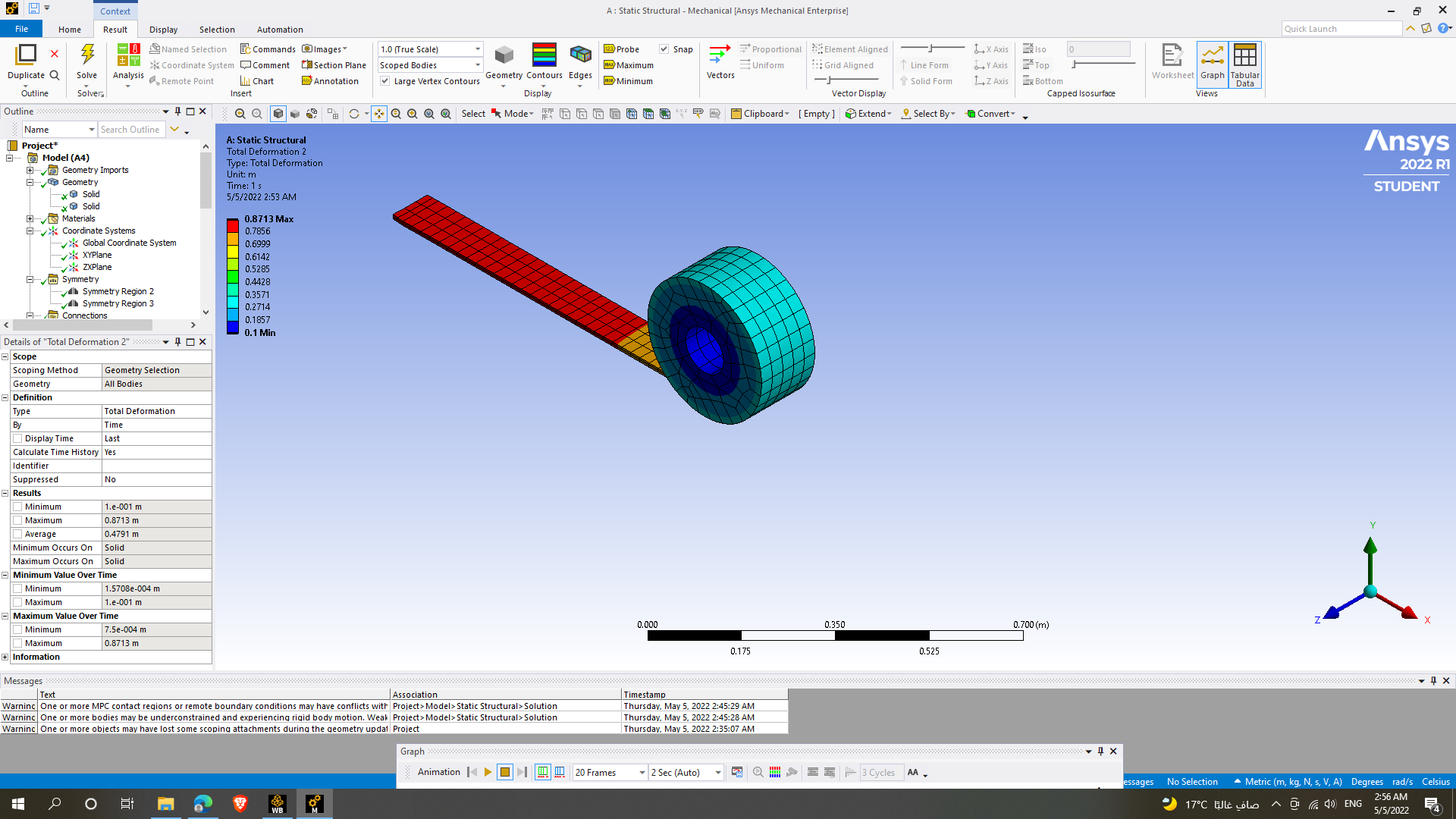

SubscriberWOOOOOOOOOOOOOOOOOOOOOOOOW it really worked

the deformation made sense

this time

how can I show the whole process not only one section, please

May 5, 2022 at 1:00 amMay 5, 2022 at 1:04 amali_elsharkawy

SubscriberMay 5, 2022 at 4:03 pmSean Harvey

Ansys Employee

Let me share some screenshots. One moment please.

Regards Sean

May 5, 2022 at 4:34 pmSean Harvey

Ansys Employee

Congratulations. We have a video on symmetry Understanding When to Take Advantage of Symmetry Using Ansys Mechanical - YouTube

If you go to time 16:21 it explains how to graphically expand the results using beta options. Please try that.

Regards Sean

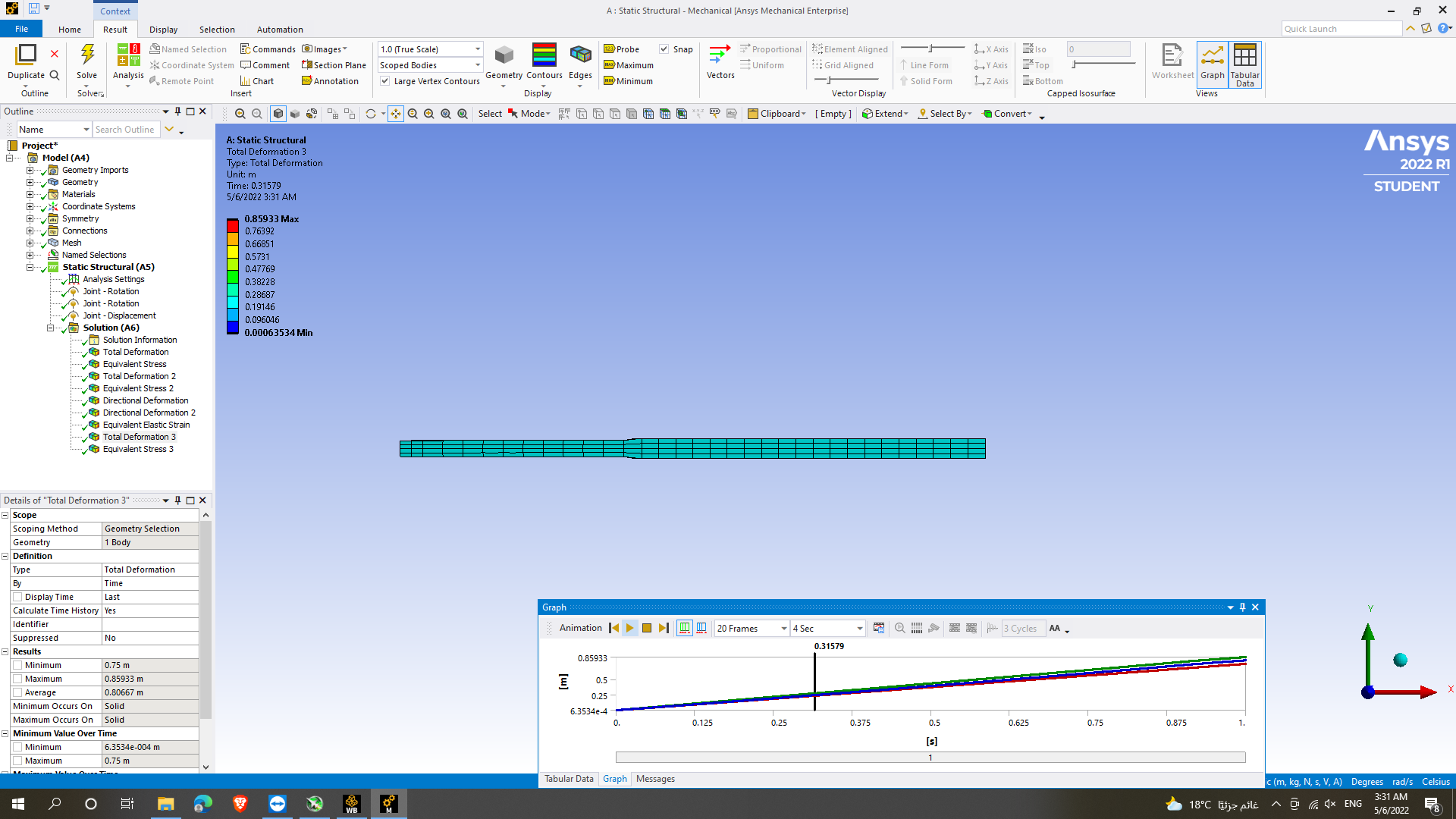

May 6, 2022 at 1:42 amMay 6, 2022 at 2:31 pmSean Harvey

Ansys Employee

Congratulations!

Regards Sean

Viewing 34 reply threads- The topic ‘2 errors in rolling process calculation’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3727

-

1328

-

1163

-

1090

-

1014

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.