-

-

September 18, 2025 at 3:58 am

hossein.hashemidehaghi

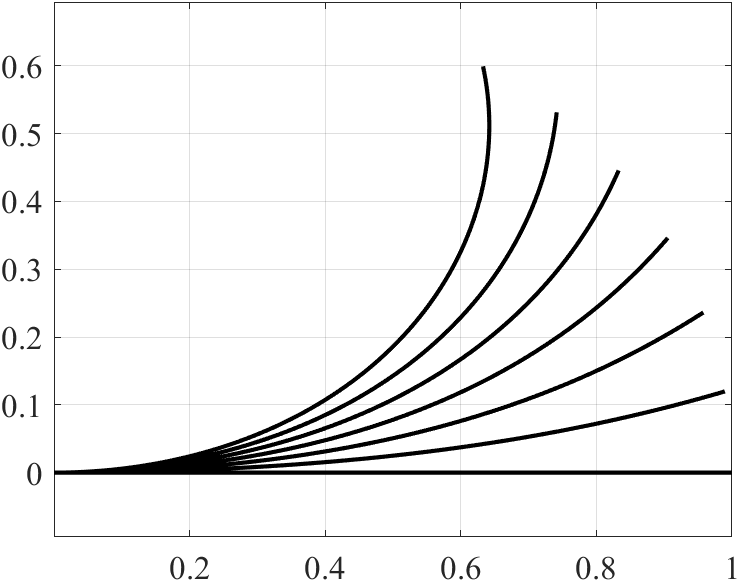

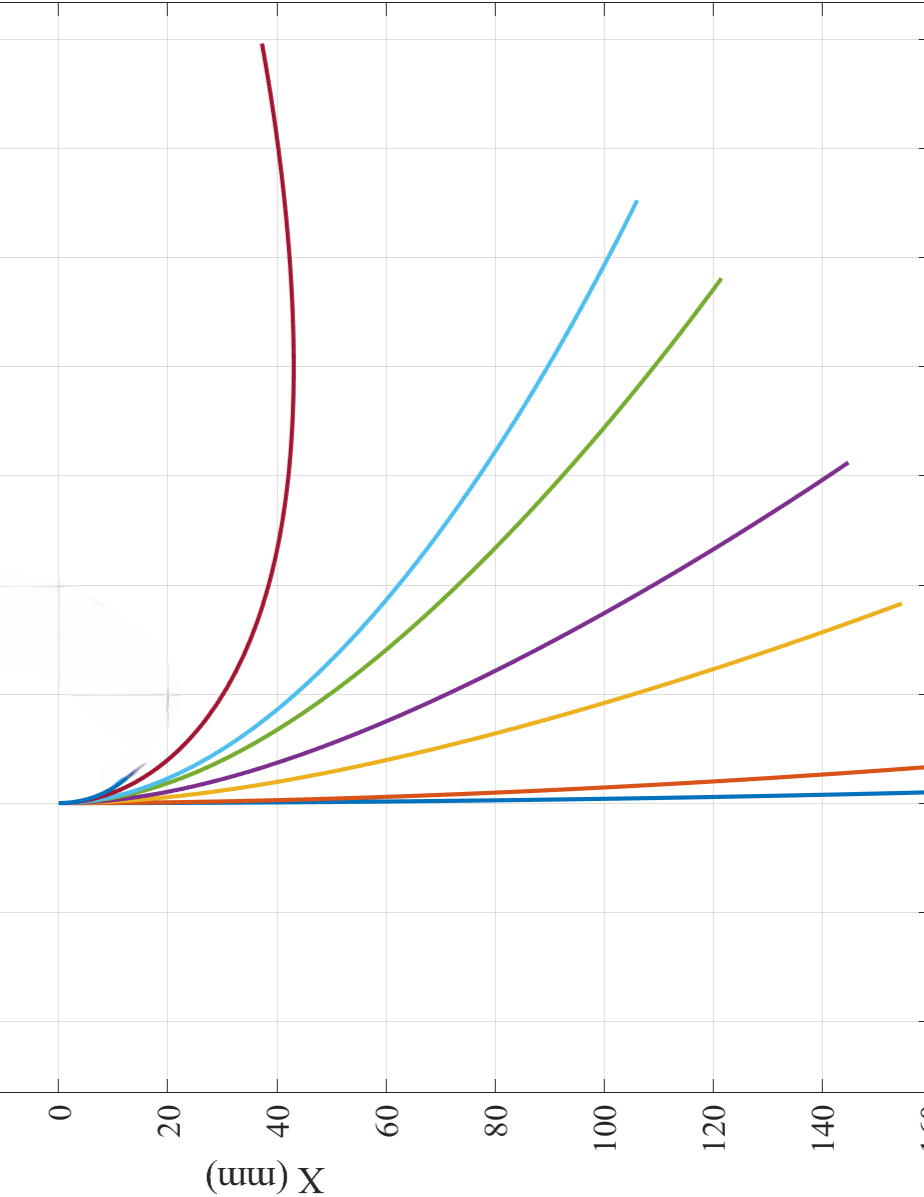

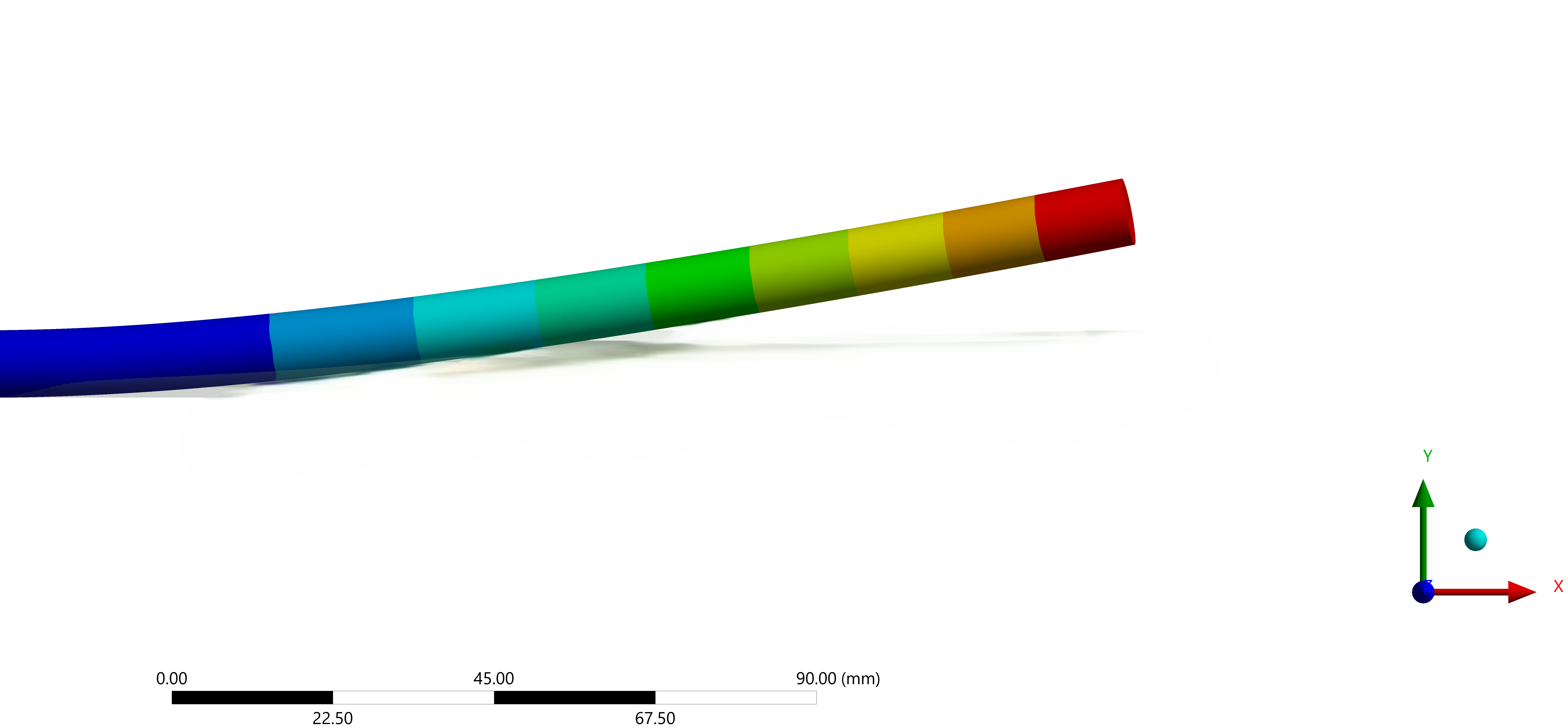

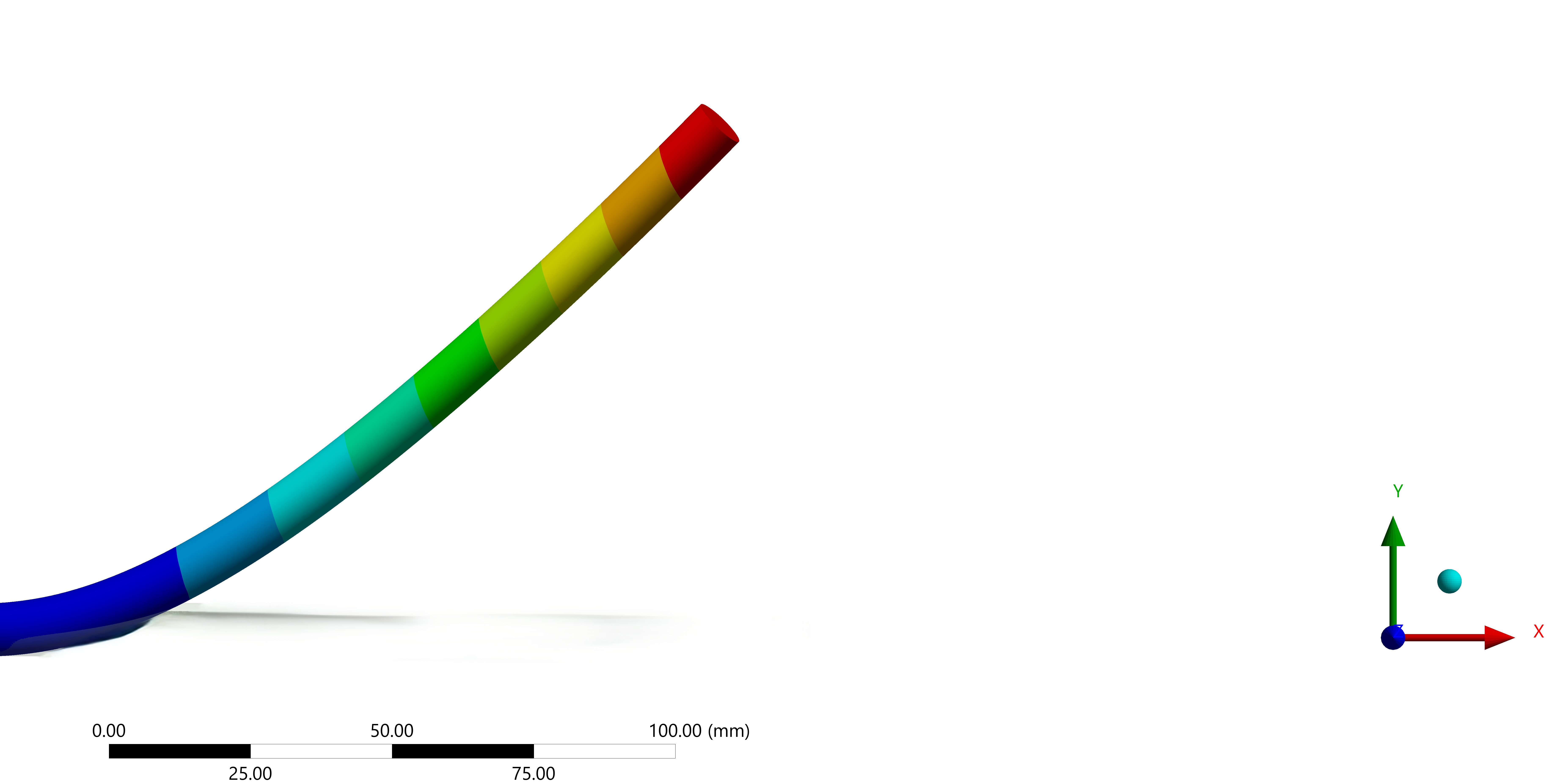

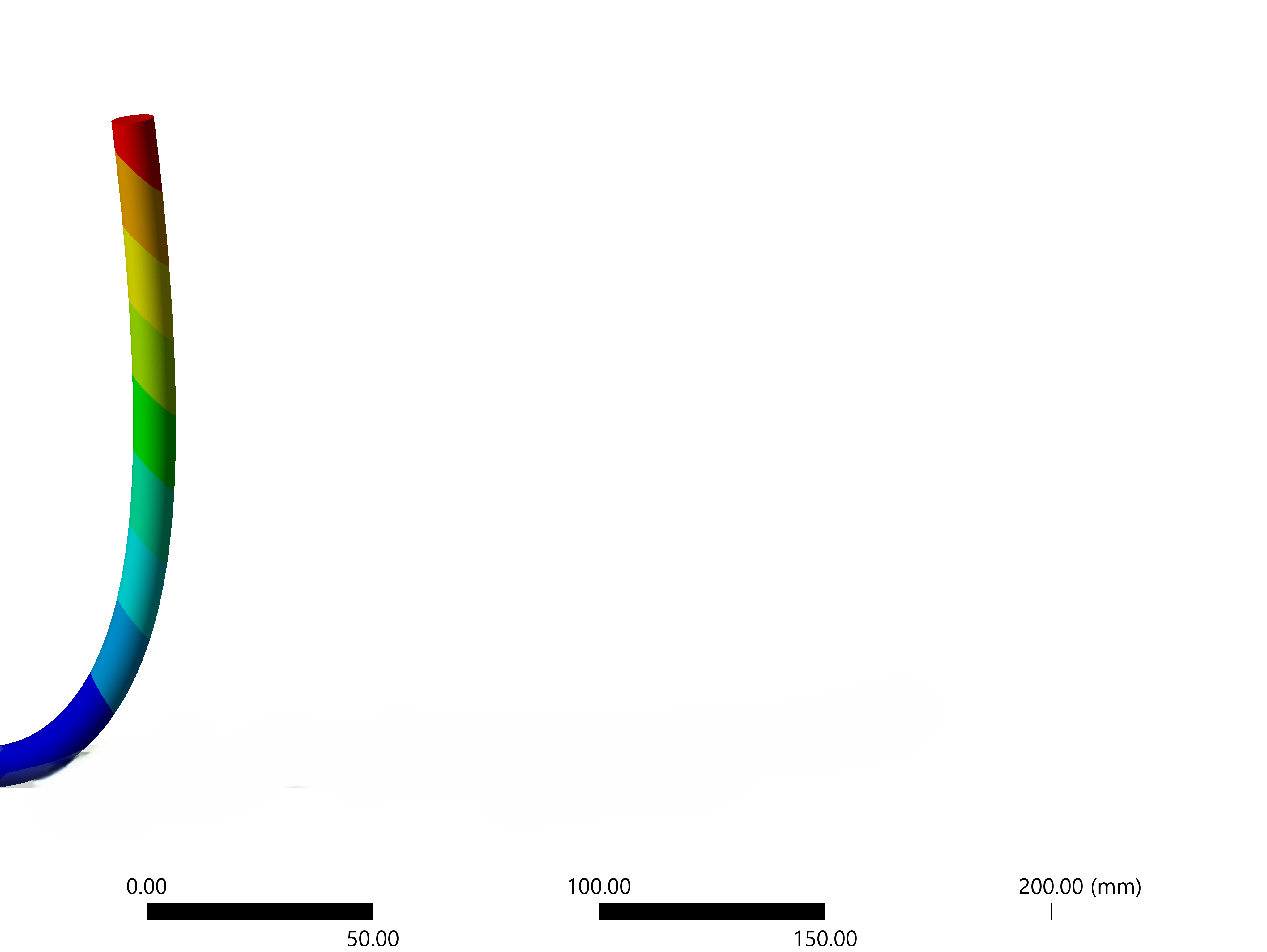

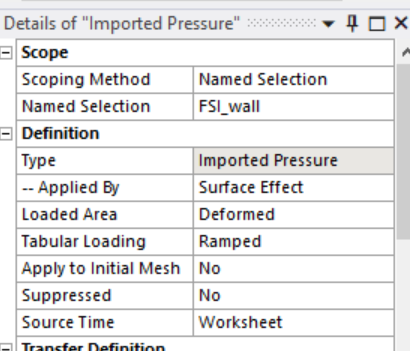

SubscriberHi everyone,I'm working on a one-way FSI simulation in ANSYS Workbench 2024R2 using Fluent + Mechanical, and I'm running into an issue related to how the imported pressure load is applied on a soft cylindrical structure (elastomer material) conveying internal flow (incompressible fluid).Setup overview:The structure is fixed at one end, free at the other like a simple cantilevered beam, with internal channels.Pressure and flowrate from Fluent are based on experimental values.In theory (and experiment), the internal pressure induces a tensile follower force along the axis, but this is balanced by a net normal follower pressure distribution along the length, resulting in a pure bending-type deformation (like an arc).For one-way FSI, I was fully aware that it doesn't update fluid pressure after deformation, so I wasn’t expecting accuracy. However, I still expected the pressure-induced forces to act perpendicular to the deforming structure during solution, producing an arc-like bending similar to the correct behavior. In the simulation results, the deformation instead resembles the case where the tensile follower force is unbalanced, suggesting the pressure acts on the initial (undeformed) geometry and not the deformed surface. This leads to an axial tension-dominated shape, which does not match my theoretical case where follower forces are balanced (check out the images below).Mechanical settings for importing load from Fluent:Large Deflection: ONMesh nonlinear adaptivity: ONApply to Initial Mesh: NOLoaded Area: DeformedMy expectation was that this should apply the imported Fluent pressure to the deformed mesh during solution, but the results suggest otherwise.Do these settings actually make Mechanical apply the pressure perpendicular like a follower perpendicular load during solution, or is it actually only applied on the initial shape?Are there any workarounds to better approximate this in one-way FSI?

The expected deformation: -

September 18, 2025 at 8:07 pm

peteroznewman

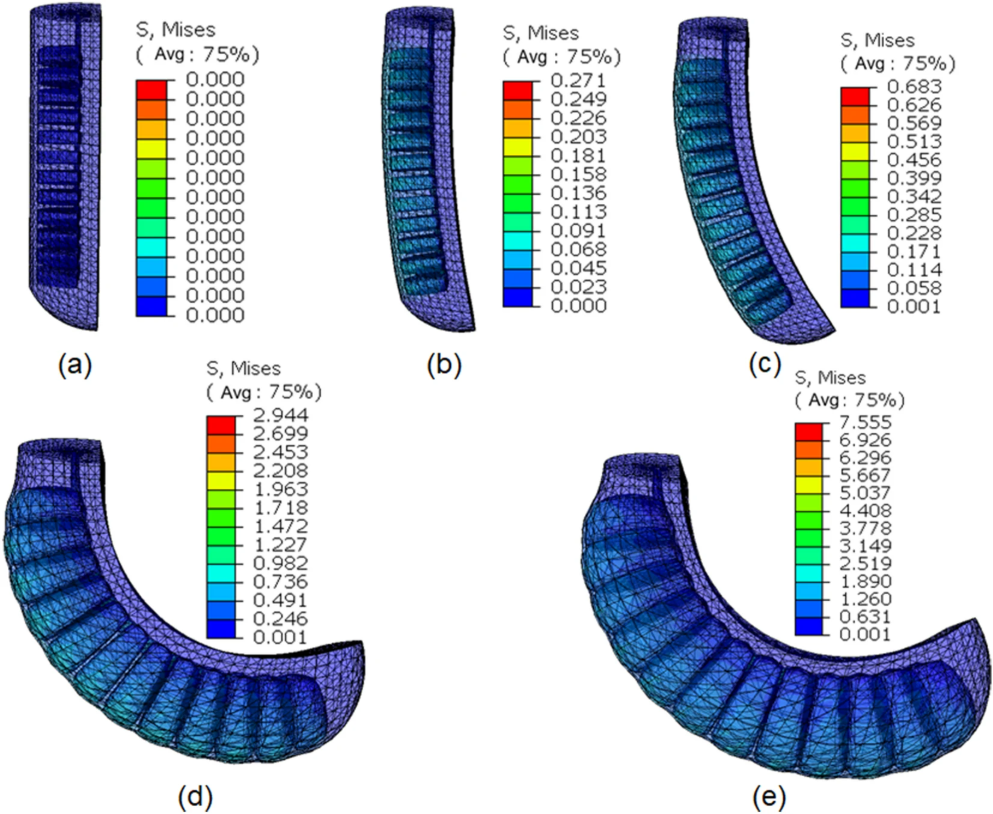

SubscriberI have seen simulations of soft actuators that deform by increasing a uniform pressure on the internal chambers. These were entirely done in the Mechanical Static Structural solver and did not need any fluid flow to see the deformation of the actuator.

From this paper: https://www.nature.com/articles/s41598-020-75346-5Have you considered not using Fluent? What benefit does Fluent provide compared with applying a uniform pressure in a mechanical load?

-

September 19, 2025 at 1:08 am

hossein.hashemidehaghi

SubscriberHi Peter,

Thanks for your response. I’ll take a look at the article you mentioned. In my case, I’m looking at a specific fluid flow that creates a complex pressure and shear distribution. It’s important to map these stresses to the channel wall to see how the structure deforms.

My question is: does the approach I described lead to a follower-type stress distribution during the solution, similar to how a constant pressure can be applied normal to a surface in Mechanical?

-

September 19, 2025 at 7:18 am

Erik Kostson

Ansys EmployeeHi

Also look at fully coupled 2 way FSI - often for complex scenarios this can be more representative of the physics and accurate/

All the best

Erik

-

- You must be logged in to reply to this topic.

- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- How to model a bimodular material in Mechanical

- APDL, memory, solid

- Meaning of the error

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

-

3907

-

1414

-

1256

-

1118

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.