Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Ncode in Workbench › Reply To: Ncode in Workbench

Thank you sir everything is clear.

There are several questions about the interface. May I ask them? I calculated a drill with attachments, the drill drills into rock (10 mm die). Nozzles are the object under study.

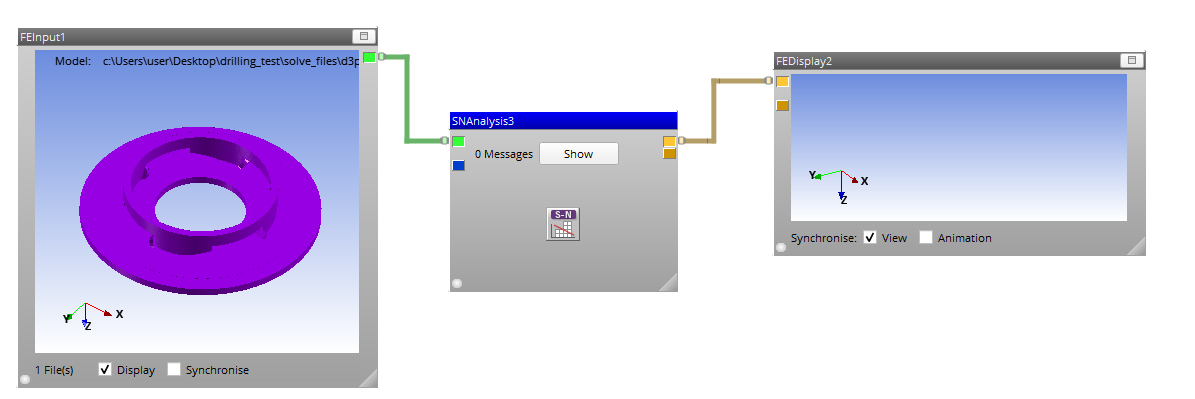

1. How to set your own/required material and SN curve for the test attachments on the drill? Should they be separated somehow?

2. What if there are several objects under study and their materials are different. How to assign material to them (each)?

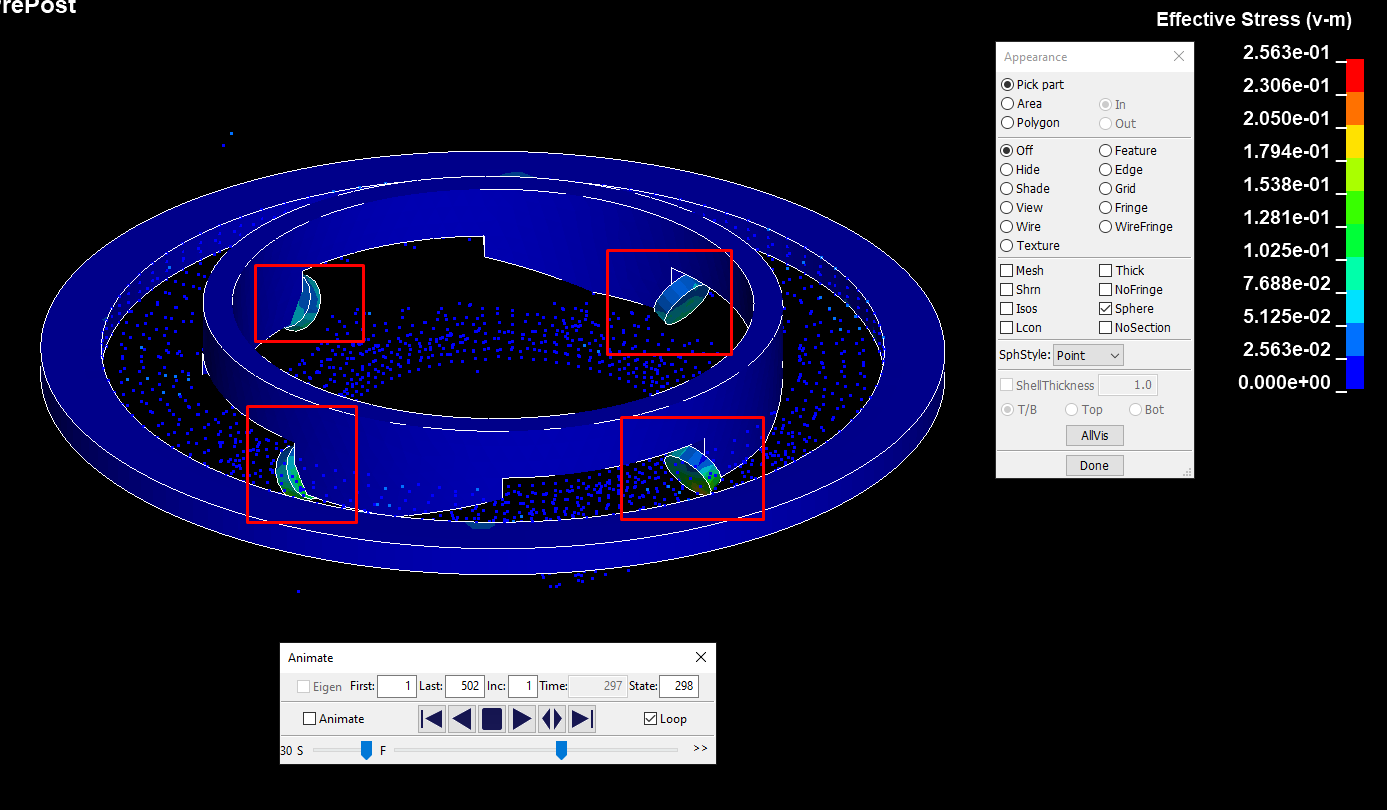

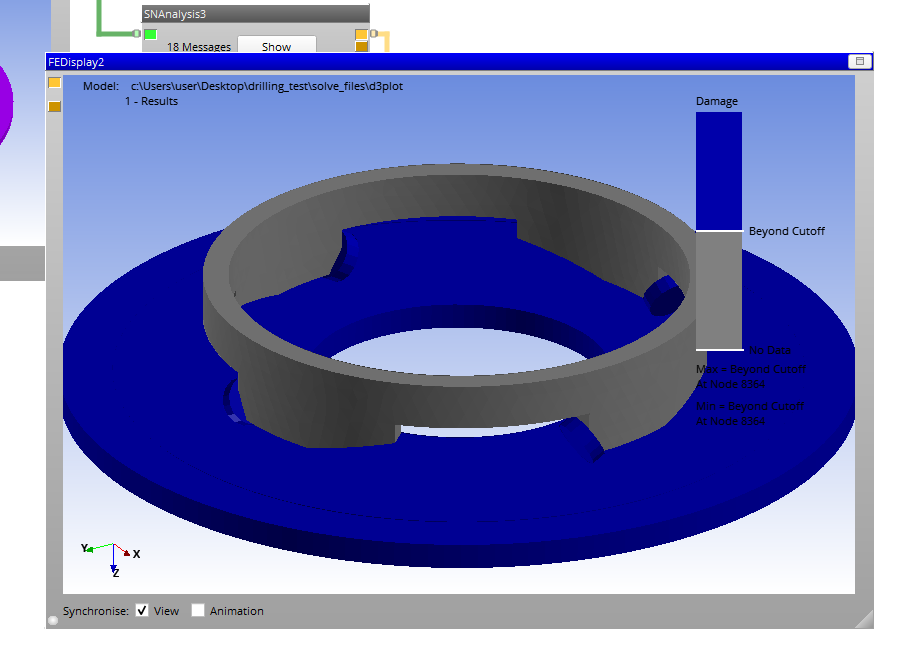

3. How to set the load for calculation? In fact, not a load, but only to understand the fatigue of the objects under study, according to the calculations performed (d3plot)? Is there a choice of timesteps, for example, select the last step and look at fatigue on it? But I don't see fatigue:

4. For example, the drill drilled a 10 mm die in the LS-Dyna calculation and recorded it in d3plot. We chose the extreme step and looked at fatigue. How can we now scale this fatigue to a larger drilling volume? For example, at 1000 mm?

5. If temperature was also studied in the calculation, what needs to be specified so that it is taken into account when calculating fatigue in the encode? Temperature data in the material? What else?

6. Also, can temperature calculations be scaled to 1000 mm of drilling, i.e. calculate how hot the object under study would be after 1000 mm? This gives an understanding of whether the solder of the bits will withstand the body of the drill.