Ansys Learning Forum › Forums › Discuss Simulation › LS Dyna › Metal forming (spinning) › Reply To: Metal forming (spinning)

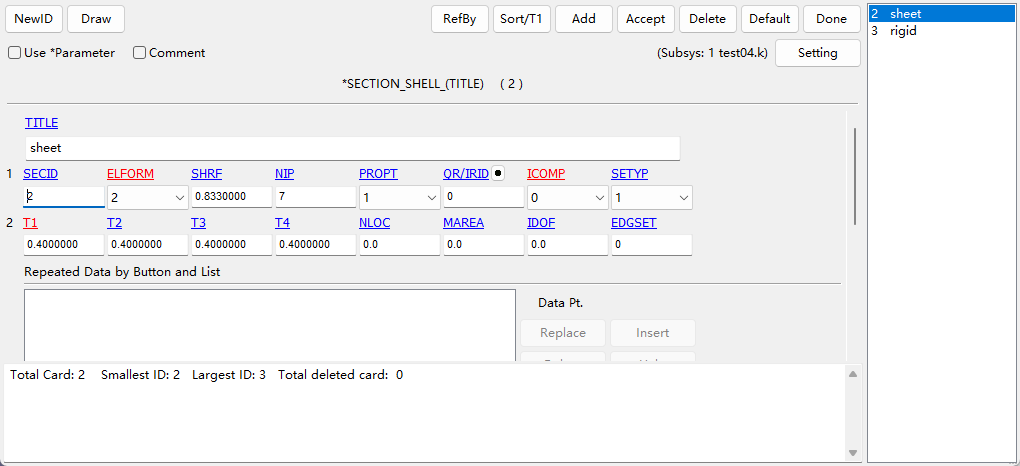

All models are shell elements.

wheel modeled is rigid and no any anomalies

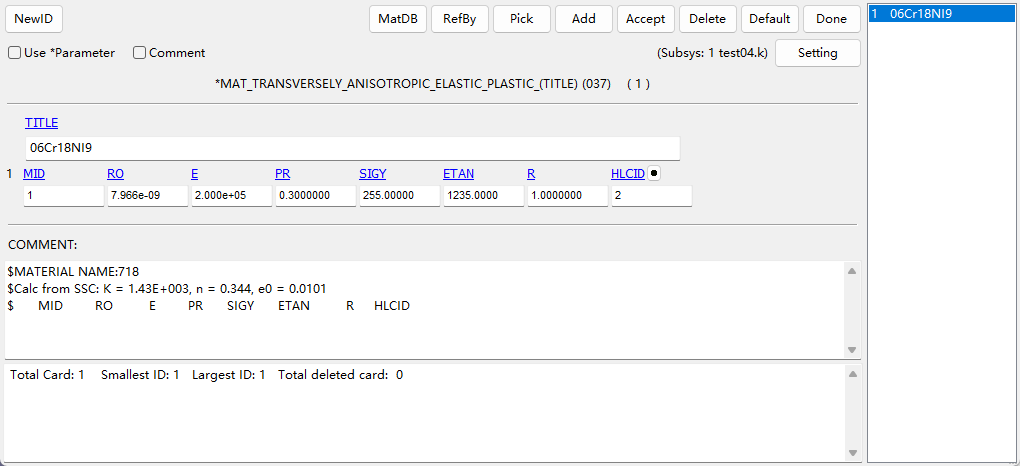

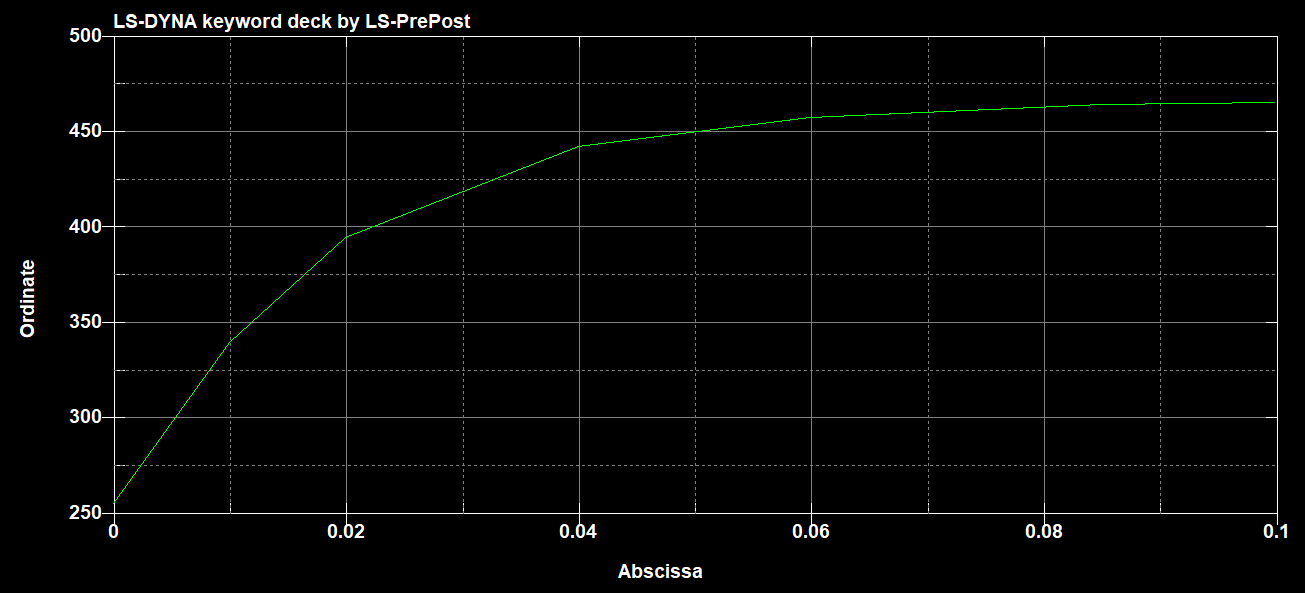

This is the material model.

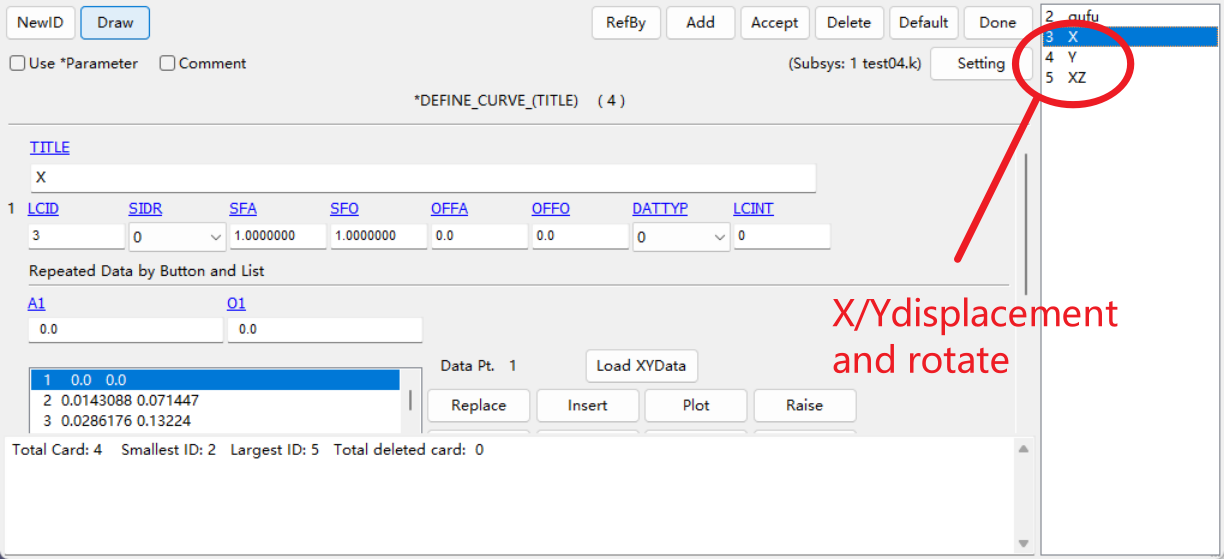

The element type and elform and material model for the blank remain the same when the rotating wheel speed is 628 rad/min and when it is 3140 rad/min. Only the rotating speed curve (situation 2) or the X/Y feed curve has changed.

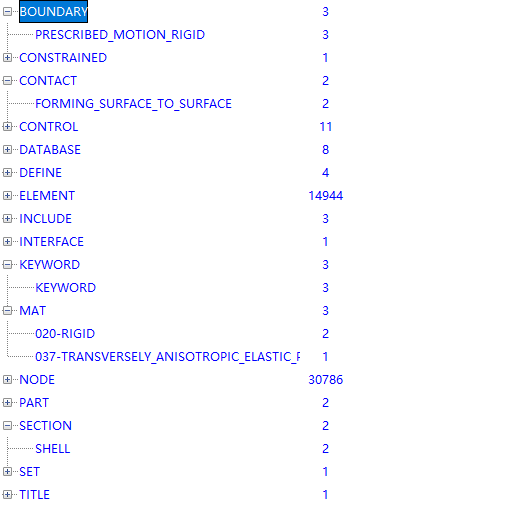

There are all keywords:

Energy issues:

situation 1(situation):

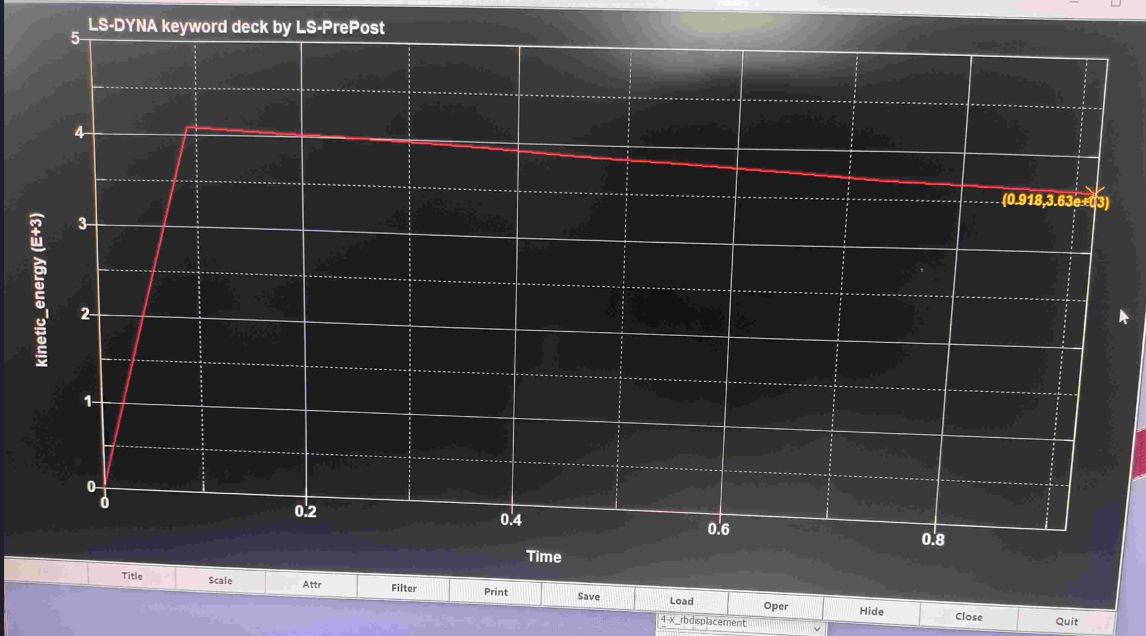

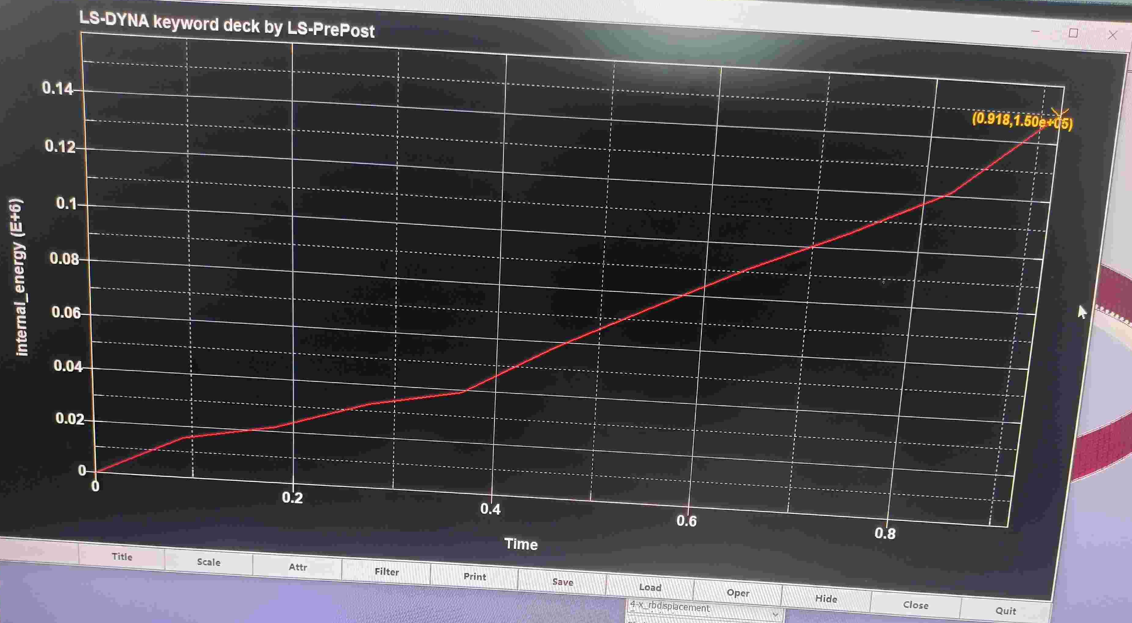

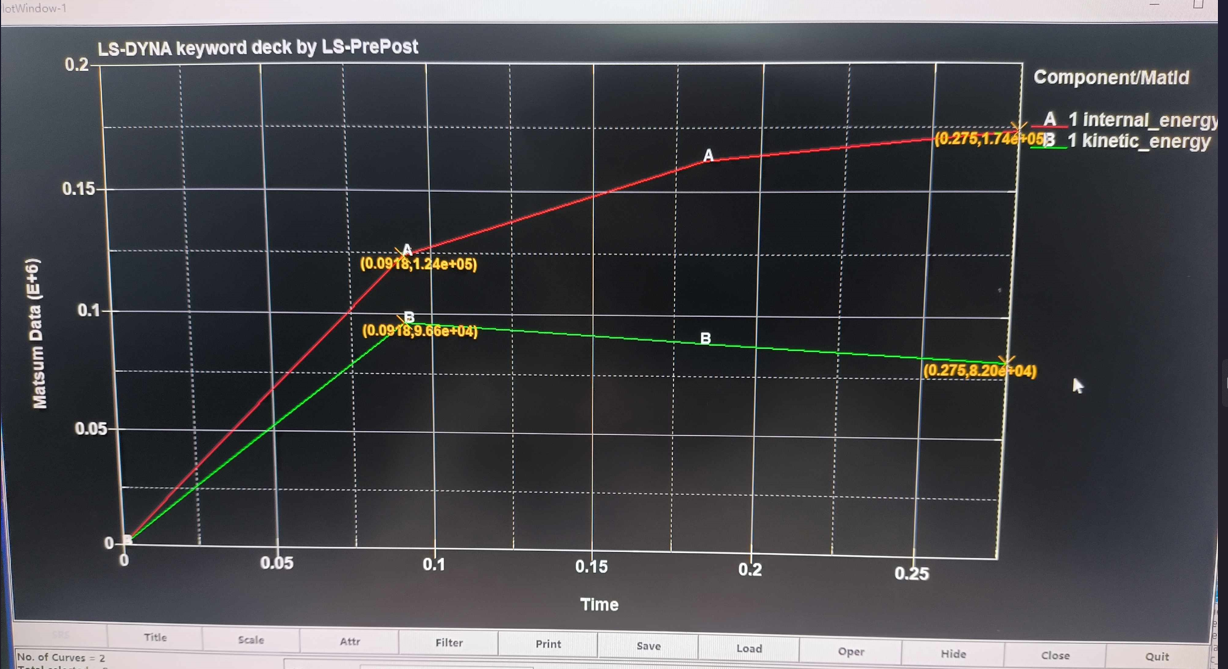

There are internal energy, kinetic energy, and hourglass energy from matsum (blank).

Kinetic energy, and hourglass energy are all no more than 5%.

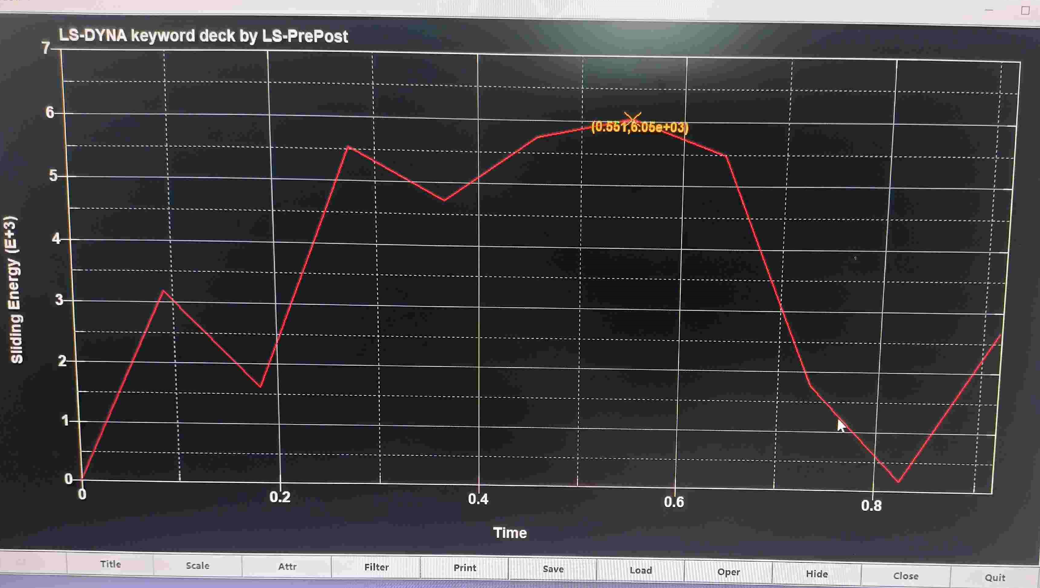

This is sliding energy from glstat.

But,I do not no how to judge.

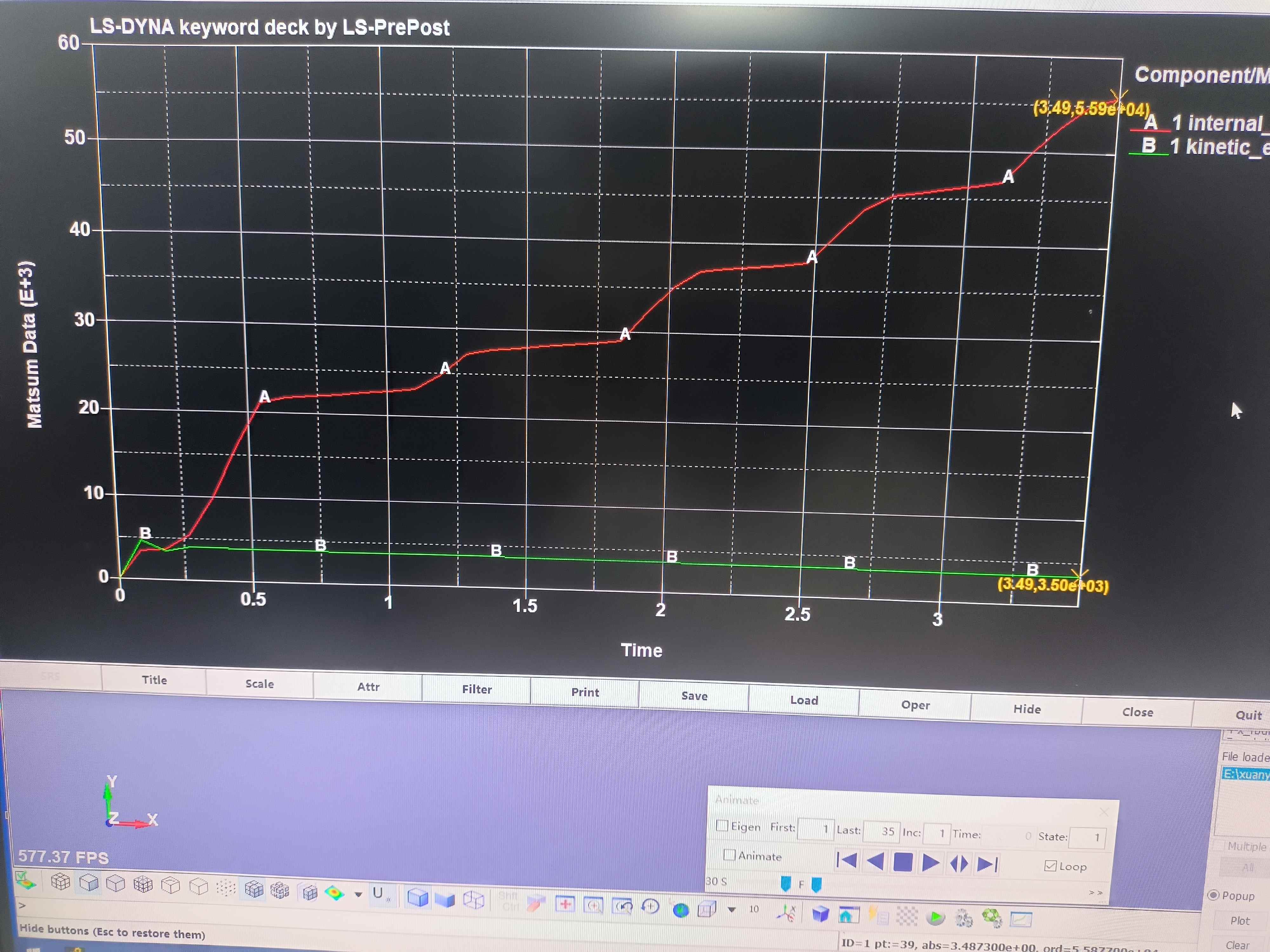

Situation 2(3140rad/min):

Perhaps due to the excessive rotational speed, the kinetic energy of the blank is too high, resulting in situation 3. Reduce the feed rate while keeping the rotational speed unchanged

Situation 3(100rad/min,feed rate 8mm/min):

Simultaneously refining the grid.

This has not been calculated yet, as it has shown a tendency for the sheet metal to deform downwards on its own.

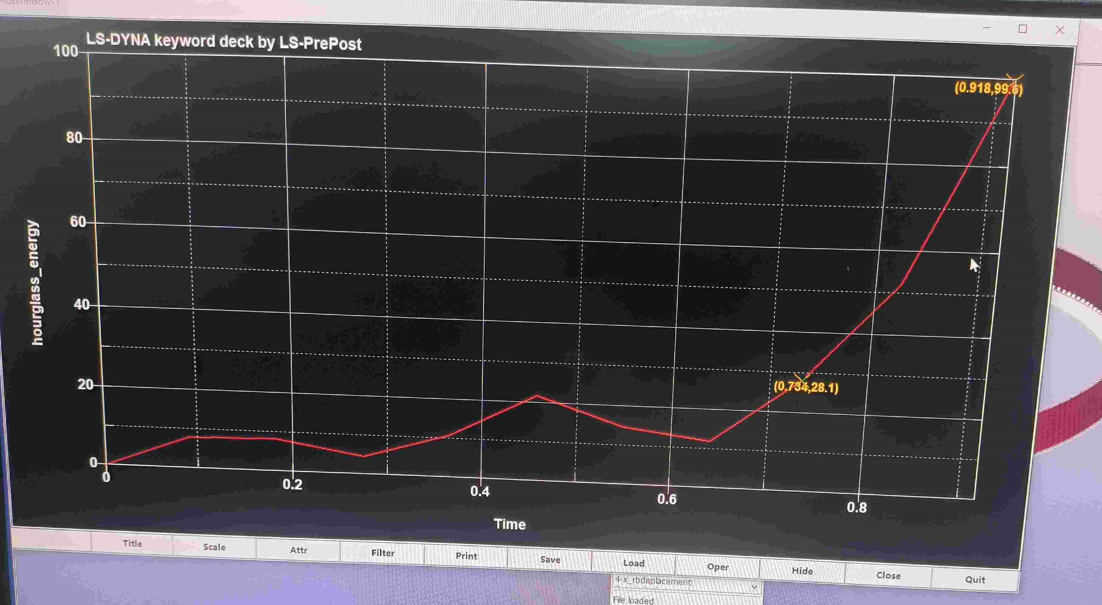

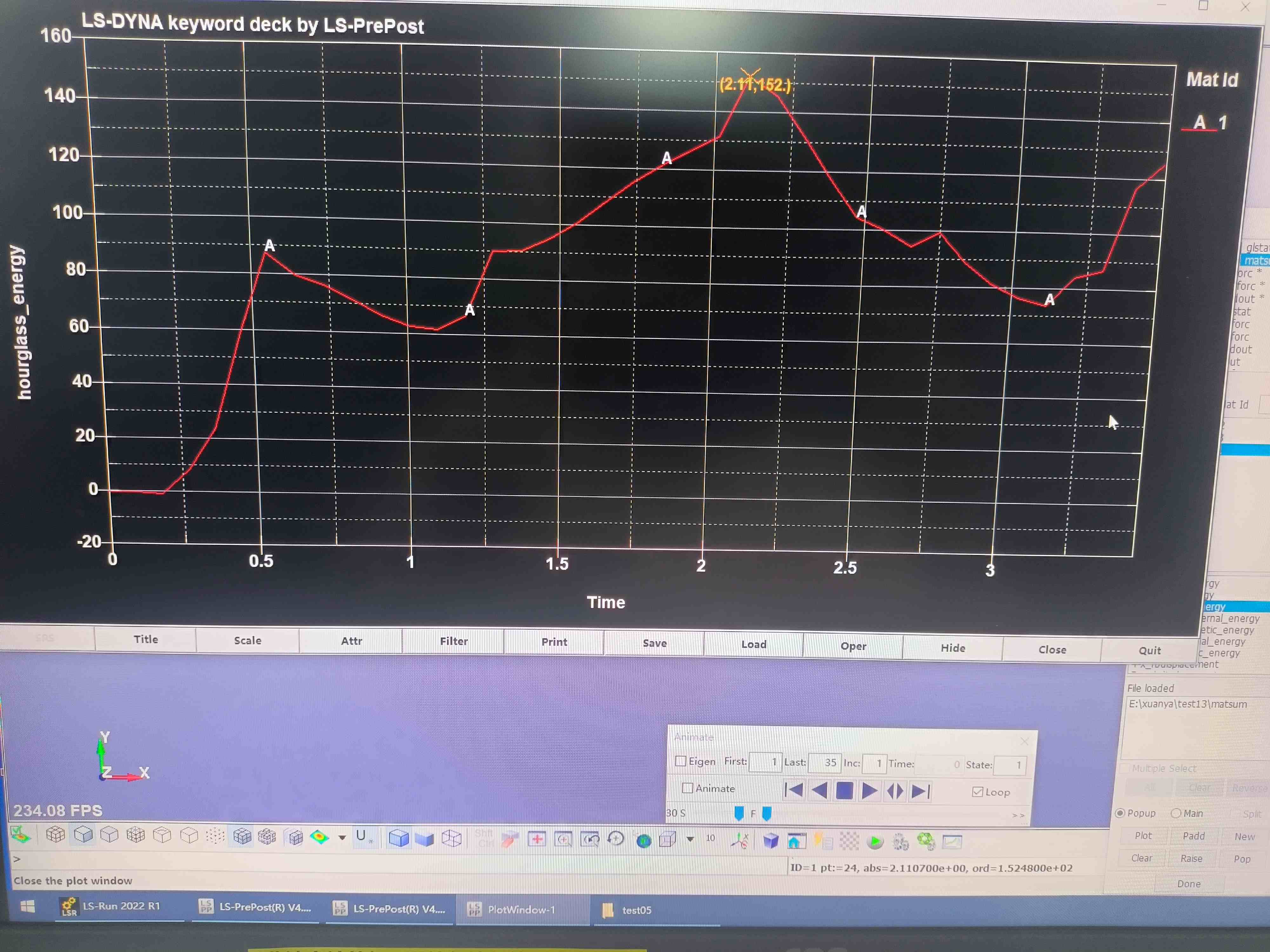

hourglass energy, and sliding energy :

I found that the slip energy in situation three is very large. Is this the reason and how to solve it?

I use ls-run2022 for the forming simulation.