Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Surface Coatings › Reply To: Surface Coatings

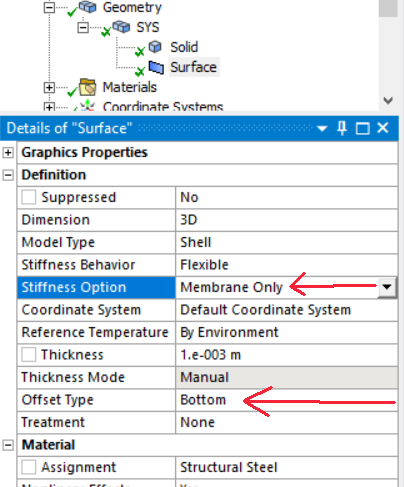

Shared topology between solids and surfaces is a bad idea. The surfaces have shell elements with 6 degrees of freedom, and the solid elements have 3 degrees of freedom. In my experience the results may not be accurate because of this. You can turn off the rotational degrees of freedom on the shells by setting the "stiffness option" to "membrane only." This may be reasonable for thin coatings and especially material that is a lot softter than the volume body material.

If you have a metal coating, it may contribute significant bending stiffness, so turning off bending on the surface may not be reasonable.

You should make sure to set the "Offset Type" to the side that shows correctly in the mesh.

Also make sure you are using the same linear/quadratic setting for the surface body as the volume body. Either set on global mesh object in Outline or on mesh methods.

Other ways to do this is through bonded contact instead of shared topology, or do not model the surface body in SpaceClaim at all. Instead insert a "Surface Coating" in Mechanical: