Ansys Learning Forum › Forums › Discuss Simulation › LS Dyna › Rock drilling › Reply To: Rock drilling

>> When you mesh your model in WB, mesh the SPG part with regular solid elements. Do not use particle method for meshing as you would do with SPH.

Then, apply the section in Mechanical to have SPG particles on the SPG body. This way, you will have SPG particles.

Note that when using SPG particles, the mesh is still a solid mesh with *ELEMENT_SOLID (there is no *ELEMENT_SPG keyword). The only thing that will decide wheather the mesh is regular FEM or SPG particles is the *SECTION_SOLID_SPG.

Let me know if this helps or not.

Yes sir, that's what I thought. I decided to clarify.

>>Also, what is this rock drilling project you are doing? Are you affiliated with a company or a university? If so, which one? Maybe we can help you better outside the Ansys Forum via a regular support case. This way, we will be able to exchange files.

Sir, I can't do this now. Maybe I'll do it later.

___

I think that soon everything will be clear how to do my task. Thanks to your answers to the questions.

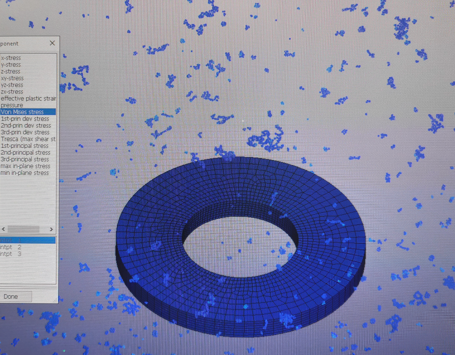

I made contact with the SPH mesh through which my drill flew and did not notice the particles.. The speed is very high (40 mm/s) and concrete particles scatter in all directions. I'll try installing a BOX card and extending the size of the workpiece for drilling. To study more closely how the drill will pass through the thickness of the particles.

The speed is very high (40 mm/s) and concrete particles scatter in all directions.

I'll try installing a BOX card and extending the size of the workpiece for drilling. To study more closely how the drill will pass through the thickness of the particles.

I will do the same test with SPG particles. But I don’t understand why they penetrate the outer ring? Maybe you need to add another contact? To prevent drilled particles from penetrating the outer ring?

I also don’t understand why there is no stress on the outer ring?