Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Layered Section Analysis in Ansys Electrical › Reply To: Layered Section Analysis in Ansys Electrical

Sorry, we have not yet have added layered feature to our thermoelectric SHELL157, electric SOLID231, or coupled field SOLID225/226/227 element types. Probably the most straightforward option would be to model the geometry of invidual layers as solid bodies. I realize this can be problematic when layers are very thin (e.g., sub-micron thick metallization). Maybe if you use uMKSV units, CAD will be lenient and allow you to model layers with such dimensions. Design Modeler may be more forgiving than Space Claim in this respect.

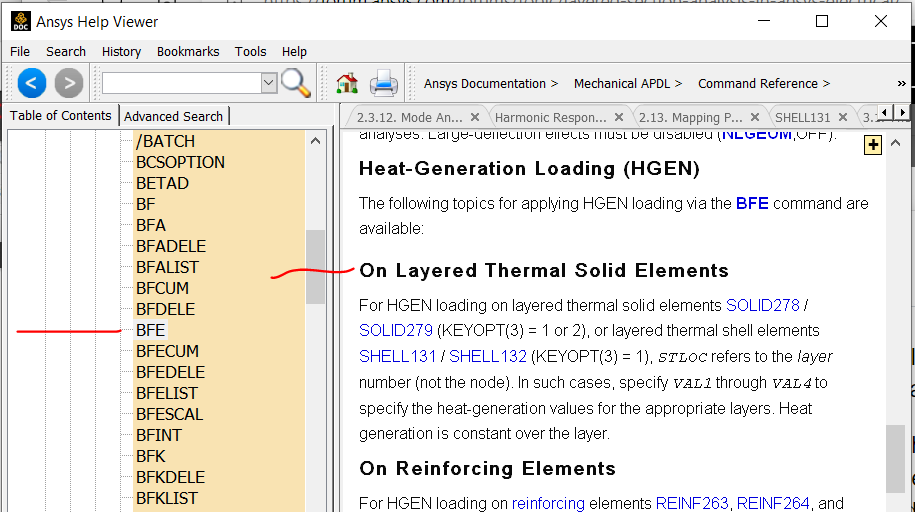

Otherwise, if you're APDL-savvy and enjoy tedium, I suppose you could try using layered themal SHELL131/132 analogously to model (mimic) electric conduction, and devise APDL to determine Joule heating (e.g., W/m^3) in individual layers (probably as the computed thermal flux squared times the inverse of thermal conductivity). The heat could then be defined for individual layers of a downstream actual thermal conduction model with the BFE command:

If temperatures are high enough to warrant consideration of temperature dependent electric resistivity in the first field analogy thermal ("electric current conduction") analysis, that can probably be done as well but it would be pretty tedious. You'd have to iterate in ways Mechanical is not designed to... use temperatures from the second actual thermal analysis to reevaluate temperature dependent thermal conductivity (masquerading as electric conductivity) in your first thermal analysis, and maybe code up some kind of do loop to continue iterations until a convergence criterion you devise is satisfied.

Probably best if you can find a way to model the layers as solid bodies and sweep mesh really thin layers if you have them (use large aspect ratios... very small edge length in the thickness direction and much larger edge length in the directions coplanar to the layer).

Best,

Bill