Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Creep limit ratio is exceeded and analysis stopped › Reply To: Creep limit ratio is exceeded and analysis stopped

I don’t have Ansys 2019 so I ran my model on Ansys 2022 R2.

I needed to correct all the Reference Temperatures in Engineering Data to 280 C and the Silicon has a Zero-Thermal-Strain Reference Temperature of 217 C which I made 280 C.

I changed the simulation to a single step of 600 seconds, with data written out 300 times (every 2 seconds). Under Analysis Settings, the Creep Limit Ratio was 3000, and Nonlinear Data was set to Yes. Initial Time Step 0.1s, Minimum Time Step 1e-6s, Maximum Time Step 10s. The solver determined that the time step had to be 4e-5s to maintain the creep ration below the limit.

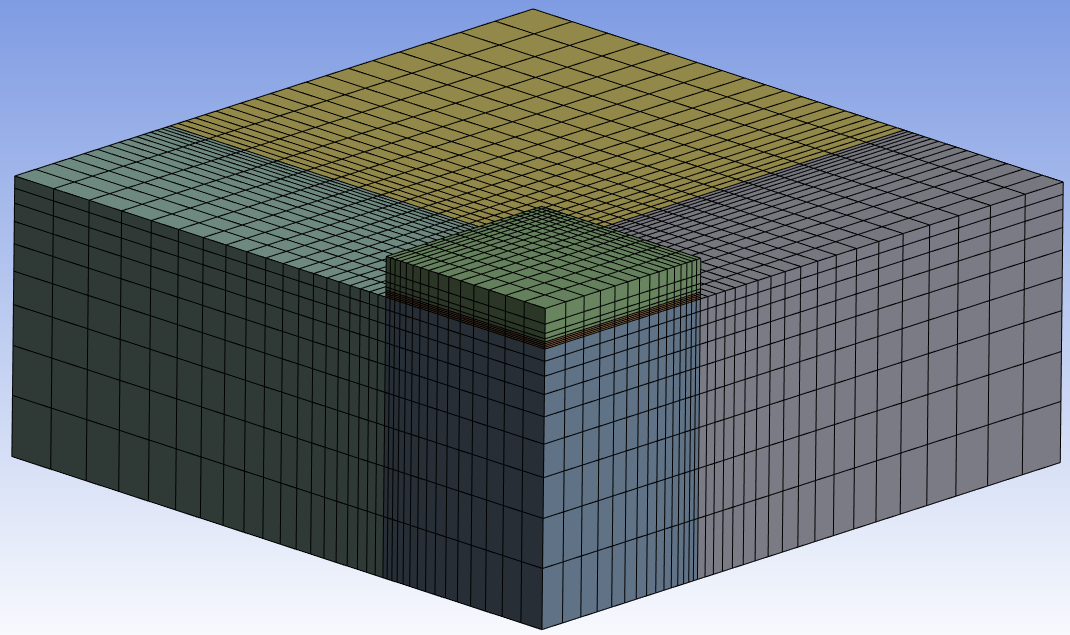

I let my 4-core laptop run overnight for 13h 17m while it performed 15,166 iterations to simulate 2.16 seconds. The mesh has 12,619 nodes and 10,800 elements. Unfortunately, with a linear change in the temperature, I don't expect the time step will change, which means this model would need 153 days to get to 600 seconds! See my next reply on a change in the thermal boundary conditions that would probably allow larger time steps as the cooling occured.

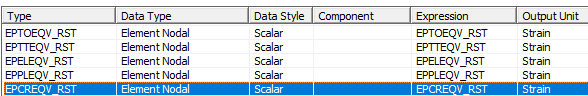

I created a User Defined Results as highlighted below, scoped to just the body with the creep material.

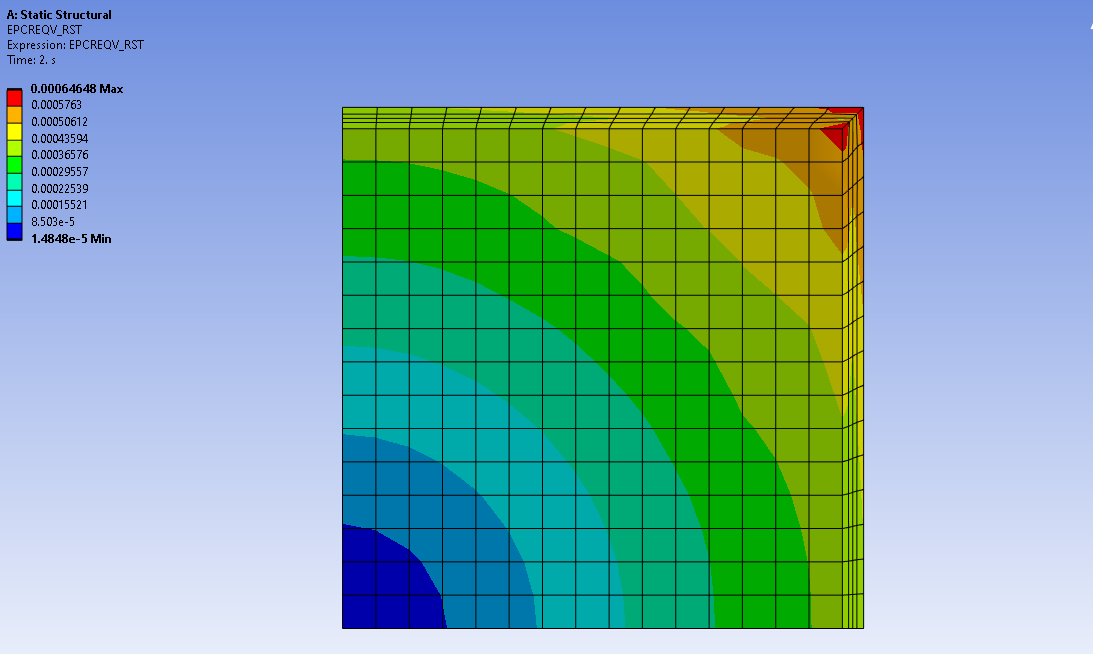

Looking up from below, at the 2 second mark we see the eqivalent creep strain.

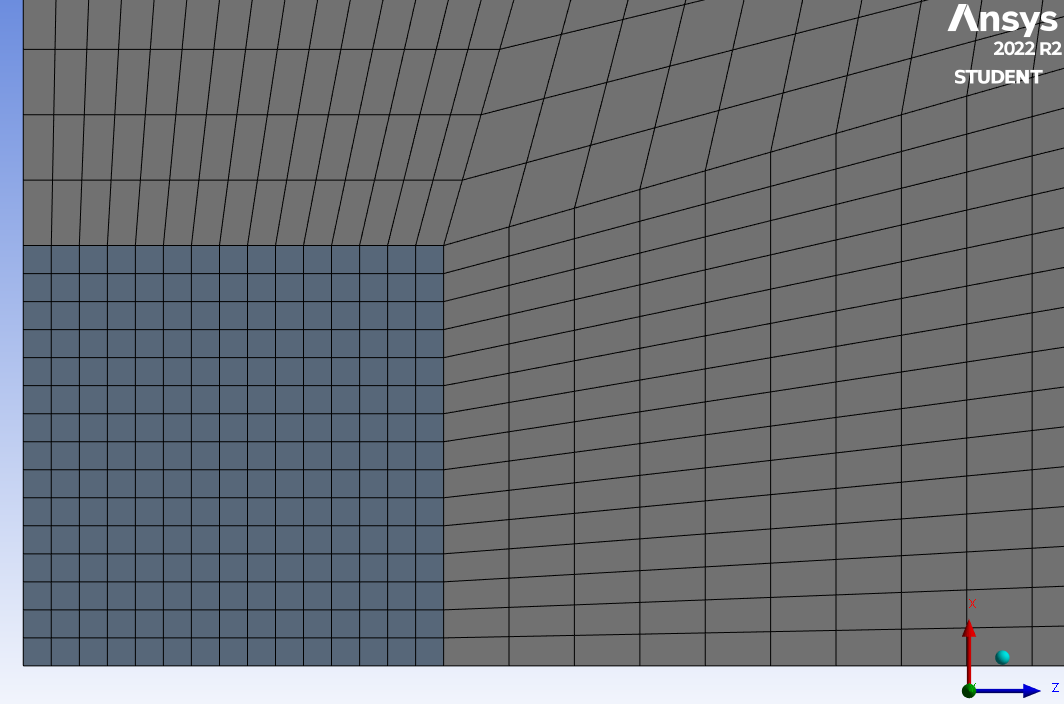

Seeing this gave me an idea that the mesh on the center column of the silicon, creep copper and base copper t hat I should have biased the elements size to put smaller elements toward the edges and larger elements toward the center, which is the lower left corner of these images. I would also split the large L-shaped block into 3 blocks to improve the element shapes from this:

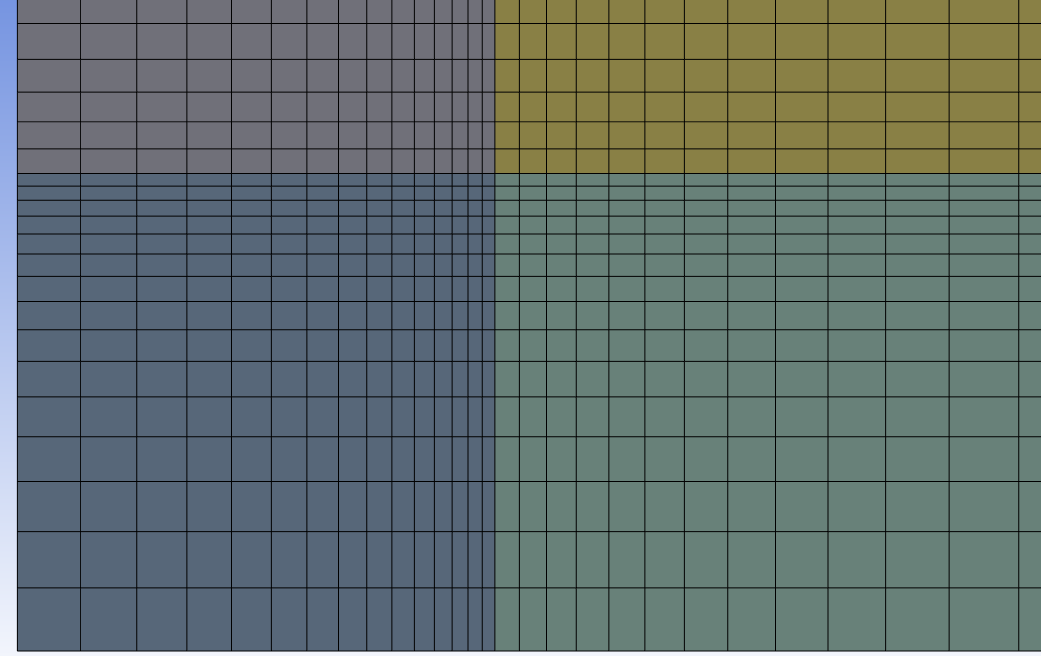

To this: