Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Is this a singularity or an actual stress concentration? › Reply To: Is this a singularity or an actual stress concentration?

December 20, 2021 at 9:58 pm

Subscriber

If you make the failure go away by reducing the mesh element size, then there would be nothing to disregard. Try it and let me know what happens.

My approach to this problem would be to understand the failure. I use the Tsai-Wu failure criterion, which is very similar to the Hoffman criterion. While these criterion are useful for predicting failure, they don't tell you the failure mode. You have to do more work to understand the failure mode, and until you understand the failure mode, it is difficult to make changes to eliminate the failure from the design.

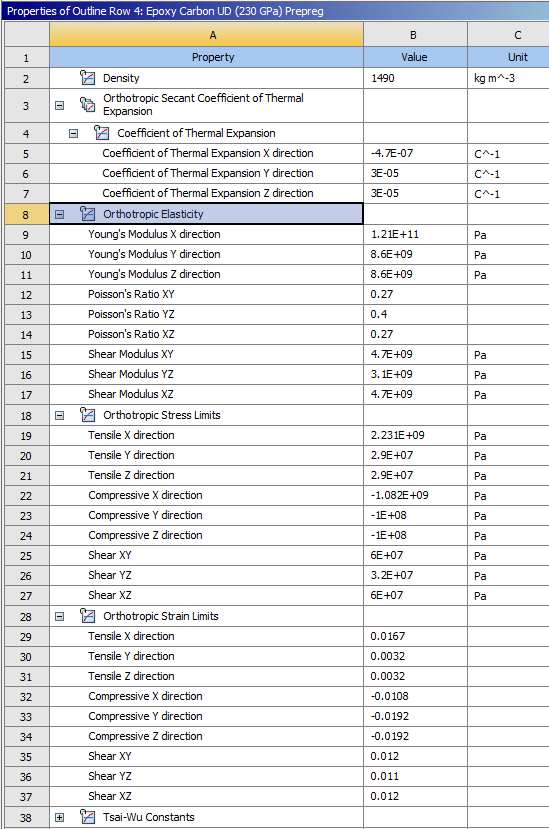

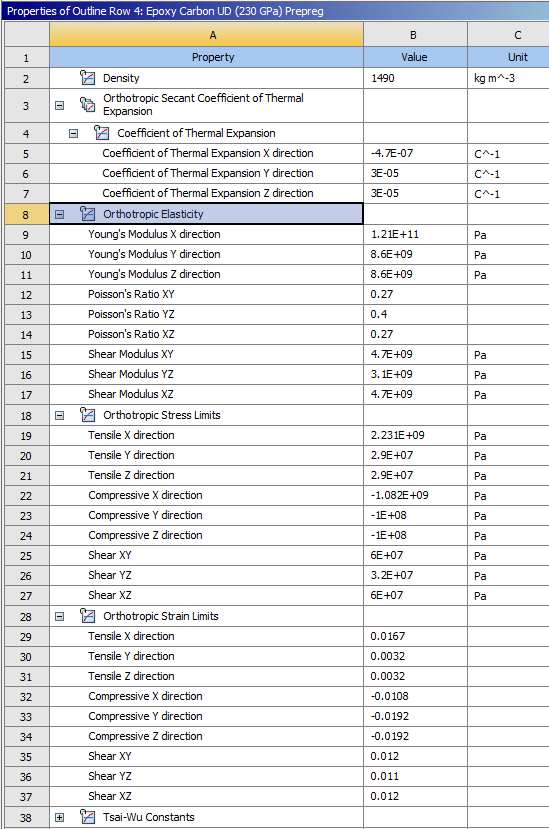

The blank form for an orthotopic material is not useful for discussing failure modes. Below is a material ANSYS provides in the Composite Library. It is one ply of unidirectional (UD) carbon fiber in an epoxy matrix. The coordinate system for this is the X direction is the fiber direction and has the high stiffness and strength of the fiber, while the Y and Z directions are the lower stiffness and strength of the matrix. These coordinate axes are element local coordinates, not global coordinates.

I'm not too familiar with ACP/Pre, let's say Ply 1 is at 0 degrees and that element direction lines up with Global X axis. If you plot the Normal Stress in X, and the stress exceeded the Orthotropic Tensile X direction Stress Limit, we would say that is a Tensile Fiber failure. If you plot the Normal Stress in Y, and the stress exceeded the Orthotropic Tensile Y direction Stress Limit, we would say that is a Tensile Matrix Failure.

I'm not too familiar with ACP/Pre, let's say Ply 1 is at 0 degrees and that element direction lines up with Global X axis. If you plot the Normal Stress in X, and the stress exceeded the Orthotropic Tensile X direction Stress Limit, we would say that is a Tensile Fiber failure. If you plot the Normal Stress in Y, and the stress exceeded the Orthotropic Tensile Y direction Stress Limit, we would say that is a Tensile Matrix Failure.

I asked you what direction the ply on the inner surface of the wing (call it ply 1) was oriented. Since you didn't answer, I'll assume ply 1 is along the length of the wing. That is the ply that is bonded to the spar. Plot ply 1 normal stress in the chord direction and compare that with the Stress Limits in the Y direction. If the stress has exceeded the limits, then the failure mode is a matrix failure. Rotating the entire layup 90 degrees might make that failure go away, because the higher Stress Limits in the X direction would now be used.

Alternatively, if ply 1 is already aligned with the chord direction, then rotating the entire layup is not going to help.

My approach to this problem would be to understand the failure. I use the Tsai-Wu failure criterion, which is very similar to the Hoffman criterion. While these criterion are useful for predicting failure, they don't tell you the failure mode. You have to do more work to understand the failure mode, and until you understand the failure mode, it is difficult to make changes to eliminate the failure from the design.

The blank form for an orthotopic material is not useful for discussing failure modes. Below is a material ANSYS provides in the Composite Library. It is one ply of unidirectional (UD) carbon fiber in an epoxy matrix. The coordinate system for this is the X direction is the fiber direction and has the high stiffness and strength of the fiber, while the Y and Z directions are the lower stiffness and strength of the matrix. These coordinate axes are element local coordinates, not global coordinates.

I'm not too familiar with ACP/Pre, let's say Ply 1 is at 0 degrees and that element direction lines up with Global X axis. If you plot the Normal Stress in X, and the stress exceeded the Orthotropic Tensile X direction Stress Limit, we would say that is a Tensile Fiber failure. If you plot the Normal Stress in Y, and the stress exceeded the Orthotropic Tensile Y direction Stress Limit, we would say that is a Tensile Matrix Failure.

I'm not too familiar with ACP/Pre, let's say Ply 1 is at 0 degrees and that element direction lines up with Global X axis. If you plot the Normal Stress in X, and the stress exceeded the Orthotropic Tensile X direction Stress Limit, we would say that is a Tensile Fiber failure. If you plot the Normal Stress in Y, and the stress exceeded the Orthotropic Tensile Y direction Stress Limit, we would say that is a Tensile Matrix Failure.I asked you what direction the ply on the inner surface of the wing (call it ply 1) was oriented. Since you didn't answer, I'll assume ply 1 is along the length of the wing. That is the ply that is bonded to the spar. Plot ply 1 normal stress in the chord direction and compare that with the Stress Limits in the Y direction. If the stress has exceeded the limits, then the failure mode is a matrix failure. Rotating the entire layup 90 degrees might make that failure go away, because the higher Stress Limits in the X direction would now be used.

Alternatively, if ply 1 is already aligned with the chord direction, then rotating the entire layup is not going to help.