TAGGED: damper, damping-coefficient, damping-effect, electromagnetics, vibration

-

-

April 24, 2021 at 9:01 am

dhruvdeshwal17

SubscriberI have modelled an eddy current damper, done its transient analysis. I got the various results , but keen interest is to calculated the damping force and damping coefficient associated with the dampers. Please suggest the procedure to calculated the same.nEddy Current dampers ( Basic Working) - In general ECD consist of a conducting plate and a magnet, which are placed adjacent to each other with a certain gap. A velocity (supposed) is given to the plate and the magnet remains stationary. So, as the plate move, the plate will see a change in a magnetic field by which eddy current will be generated in the plate and due to this current a magnetic field will be generated of opposite polarity as that of the magnet. Due to this generated magnetic field, the magnet experiences a force which is the damping force (In this case). n -

April 28, 2021 at 11:21 am

NKC

Forum ModeratorHi D_D ,

Which Ansys tool are you using?

If you are using Ansys Maxwell, you can calculate the force experienced by the magnet by assigning the force parameter to the magnet.

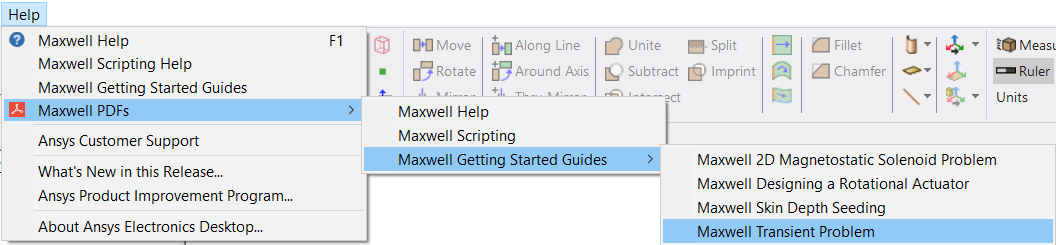

You can look at the Below help section to understand how to set up a transient problem.

If this did not solve your problem, explain How is your simulation setup and what results do you get with the help of some screenshots. This will help interpret the problem correctly.

If this did not solve your problem, explain How is your simulation setup and what results do you get with the help of some screenshots. This will help interpret the problem correctly.Regards,

Navya

-

April 28, 2021 at 11:46 am

dhruvdeshwal17

SubscriberHi Array

Im using ANSYS 16.0 APDL

-

August 25, 2022 at 1:21 am

wrbulat

Ansys EmployeeIf the moving conductive region is continuous in the direction of motion (e.g., a rotating ring or disk), you can do this with a static analysis using the velocity effects feature. Mesh the conductor with SOLID236 and assign the velocity to the nodes of the conductor mesh using BF,ALL,VELO,vx,vy,vz,omegax,omegay,omegaz (specify angular velocity in units of radians/s). If you copy the text I pasted below into a text file and read it into MAPDL with the /INPUT command, you'll have an example:

fini/cle/pnu,mat,1/num,1/vie,1,1,2,3/fil,236/sys,del 236*.pngC*********************************************************C*** PARAMETERSC*********************************************************pi=acos(-1)k_nl=0 ! k_nl=0: LINEAR, k_nl=1: NONLINEARkey_opt_2=0 ! KEYOPT(2) - 0: TRUE VOLT, 2: TIME INTEGRATED ELEC POTkey_opt_7=0 ! KEYOPT(7) - 0: ALL NODES, 1: CORNER NODESkey_opt_8=0 ! KEYOPT(8) - 0: MAXWELL, 1: LORENTZr_PM=0.010 ! PM RADIUSr1_cyl=0.012 ! CYLINDER INNER RADIUSr2_cyl=0.015 ! CYLINDER OUTER RADIUSr_dmn=0.025 ! RADIUS OF SURROUNNDING DOMAINr_gap=0.5*(r_PM+r1_cyl) ! RADIUS OF ARMINT INTERFACE IN AIRGAPdivr_cyl=7 ! # OF DIVISIONS IN RADIAL DIRECT IN CYLINDERdivz=5 ! # OF ELEMENT DIVISIONS IN AXIAL DIRECTIONl=0.050 ! CYLINDER LENGTHl_end=0.025 ! LENGTH OF DOMAIN EXTENDING BEYOND END OF CYLINDERHc_PM=1e6 ! PM COERCIVITYmur_PM=1.04 ! PM RELATIVE PERMEABILITYrsv_cyl=3e-8 ! CYLINDER ELECTRIC RESISTIVITYmur_cyl=1000 ! CYLINDER RELATIVE PERMEABILITY (USED IF k_nl=0)RPM=50 !6000 ! ANGULAR VELOCITY, RPM (38 OK, 39 FAILS)t_init=1e-9 ! TIME TO ESTABLISH INITIAL FIELD (NOT USED)thta=45 ! ROTOR POSITION AT END OF TRANSIENTt_final=t_init+(thta/360)/(RPM/60) ! TIME AT END OF TRANSIENTnsteps=5 ! # OF TIME STEPS*if,k_nl,eq,1,then/title,SOLID236 V15 VELOCITY EFFECTS, %RPM% RPM, CYL PERMEABILITY NONLINEAR*else/title,SOLID236 V15 VELOCITY EFFECTS, %RPM% RPM, mur_cyl = %mur_cyl%*endifC*********************************************************C*** GEOMETRYC*********************************************************/prep7asel,none ! PMpcir,r_PM,,0,90aatt,2,2,200asel,none ! CYLINDERpcirc,r1_cyl,r2_cyl,0,90aatt,3,3,200allscm,keep_a,areaasel,none ! SURROUNDING AIRpcirc,0,r_gap,0,90pcirc,r_gap,r_dmn,0,90cm,scrap_a,areaalls ! BOOLEAN SUBTRACTIONasba,scrap_a,keep_a,,dele,keepcmse,u,keep_aaatt,1,1,200allsaploC*********************************************************C*** ATTRIBUTES, MESHC*********************************************************et,1,236 ! AIRkeyo,1,7,key_opt_7 ! FORCE OUTPUTkeyo,1,8,key_opt_8 ! FORCE CALCULATIONmp,murx,1,1et,2,236 ! PMkeyo,2,7,key_opt_7 ! FORCE OUTPUTkeyo,2,8,key_opt_8 ! FORCE CALCULATIONmp,murx,2,mur_PMmp,mgyy,2,Hc_PMet,3,236,1 ! CYLINDERkeyo,3,2,key_opt_2 ! TRUE/TIME INTEGRATED VOLTkeyo,3,7,key_opt_7 ! FORCE OUTPUTkeyo,3,8,key_opt_8 ! FORCE CALCULATIONmp,murx,3,mur_cylmp,rsvx,3,rsv_cylmp,rsvx,3,rsv_cyl*if,k_nl,eq,0,thenmp,murx,3,mur_cyl*elsefifi1=0.94 ! hyperco 50 b-h 0.014in input, STATOR minimumtb,bh,3tbpt,defi,0,0tbpt,defi,2/0.01257,1.5*fifi1tbpt,defi,4/0.01257,1.8*fifi1tbpt,defi,5/0.01257,1.87*fifi1tbpt,defi,6/0.01257,1.93*fifi1tbpt,defi,8/0.01257,2.0*fifi1tbpt,defi,10/0.01257,2.05*fifi1tbpt,defi,20/0.01257,2.15*fifi1tbpt,defi,40/0.01257,2.195*fifi1tbpt,defi,50/0.01257,2.21*fifi1tbpt,defi,60/0.01257,2.225*fifi1tbpt,defi,80/0.01257,2.24*fifi1tbpt,defi,100/0.01257,2.25*fifi1tbpt,defi,150/0.01257,2.28*fifi1tbpt,defi,400/0.01257,2.4*fifi1*endifcsys,1 ! # OF DIVISIONS THRU CYL THICKNESSlsel,s,loc,x,r1_cyl+0.25*(r2_cyl-r1_cyl),r1_cyl+0.75*(r2_cyl-r1_cyl)lesi,all,,,divr_cyl,,1alls ! MESH AREASet,200,200,7ames,allcsys,1 ! FULL 360 DEGREE GEOMETRYagen,4,all,,,0,90,0csys,1 ! MERGE NODES/KPS INSIDE ARMINT INTERFACEksel,s,loc,x,0,r_gaplslk,s,1asll,s,1alls,belo,areanumm,node,1e-8,1e-8numm,kp,1e-8,1e-8csys,1 ! MERGE NODES/KPS OUTSIDE ARMINT INTERFACEksel,s,loc,x,r_gap,r_dmnlslk,s,1asll,s,1alls,belo,areanumm,node,1e-8,1e-8numm,kp,1e-8,1e-8eploC********************************************C*** EXTRUDE MESHED AREAS INTO MESHED VOLUMESC********************************************extopt,esize,divz,0extopt,aclear,1extopt,attr,1,1,1csysasel,s,mat,,1type,1vext,all,,,0,0,l/2asel,s,mat,,2type,2vext,all,,,0,0,l/2asel,s,mat,,3type,3vext,all,,,0,0,l/2extopt,attr,0,0,0vsel,s,mat,,1alls,belo,voluasel,r,loc,z,l/2type,1, $mat,1, $real,1vext,all,,,0,0,l_endvsel,s,mat,,2alls,belo,voluasel,r,loc,z,l/2type,1, $mat,1, $real,1vext,all,,,0,0,l_endvsel,s,mat,,3alls,belo,voluasel,r,loc,z,l/2type,1, $mat,1, $real,1vext,all,,,0,0,l_endallsvplocsys,1 ! MERGE NODES/KPS INSIDE ARMINT INTERFACEksel,s,loc,x,0,r_gaplslk,s,1asll,s,1vsla,s,1alls,belo,volunumm,node,1e-8,1e-8numm,kp,1e-8,1e-8cm,PM_v,volucsys,1 ! MERGE NODES/KPS OUTSIDE ARMINT INTERFACEksel,s,loc,x,r_gap,r_dmnlslk,s,1asll,s,1vsla,s,1alls,belo,volunumm,node,1e-8,1e-8numm,kp,1e-8,1e-8cm,cyl_v,volualls ! GO AHEAD AND MERGE ALL NODES - USE VELOCITY EFFECTS INSTEAD OF ARMINTnumm,node,1e-8,1e-8numm,kp,1e-8,1e-8eploC********************************************C*** FLUX PARALLEL EXTERIORC********************************************allsasel,s,extcsys,1ksel,s,loc,x,r_gaplslk,s,1asll,u,1!asel,u,loc,zda,all,azvsel,s,mat,,3alls,belo,voluasel,r,loc,zda,all,volt!alls,belo,volu!asel,r,loc,z,l/2!cp,1,volt,allC********************************************C*** APPLY VELOCTY TO ROTORC********************************************vsel,s,mat,,3alls,belo,volubf,all,velo,,,,,,RPM*2*pi/60 ! RADIANS/sfiniC********************************************C*** STATIC SOLVEC********************************************/soluallspivc,off*if,k_nl,gt,0,thenautots,on ! TURN ON AUTO TIME STEPPINGnsub,5,25,5 ! RANGE OF ALLOWABLE SUBSTEPSoutr,all,all ! SAVE ALL CALCULATED RESULTSlnsr,on ! LINE SEARCH ALGORITHM CAN HELP WITH CONVERGENCEkbc,0 ! RAMP APPLIED LOADS*endifsavesolvfiniC********************************************C*** POST PROCESSC********************************************/post1esel,s,mat,,3 ! CYLINDER MECHANICAL POWER (TORQUE TIMES OMEGA)nsleeslnemftP_mech_cyl = 2*(2*pi*RPM/60)*_tzsumesel,s,mat,,2 ! PM MECHANICAL POWER (TORQUE TIMES OMEGA)nsleeslnemftP_mech_PM = 2*(2*pi*RPM/60)*_tzsumvsel,s,mat,,3 ! DETERMINE HEAT PRODUCED IN CYLINDERalls,belo,voluset,lastetab,,jheaetab,,volusmult,ht,jhea,volussum*get,ht_total,ssum,,item,htht_total=2*ht_total/ann,dele/tla,-0.25,0.90,Net Heat in Cylinder: %ht_total% W/tla,-0.25,0.85,Cylinder Mechanical Power: %P_mech_cyl% W/tla,-0.25,0.80,PM Mechanical Power: %P_mech_PM% Wplve,b,,,,vect,,on/sho,png $plve,b,,,,vect,,on $/sho,close $/wait,2plve,jt,,,,vect,,on/sho,png $plve,jt,,,,vect,,on $/sho,close $/wait,2rsys,1plns,b,y/sho,png $plns,b,y $/sho,close $/wait,2plet,jhea,1/sho,png $plet,jhea,1 $/sho,close $/wait,2/eof-- Bill

-

- The topic ‘Calculating damping force and damping coefficient.’ is closed to new replies.

-

3587

-

1193

-

1086

-

1068

-

952

© 2025 Copyright ANSYS, Inc. All rights reserved.