TAGGED: peteroznewman

-

-

September 13, 2020 at 12:55 pm

MAMIN219

SubscriberHello sir I am attaching one research paper along with my ansys 19.2 drilling operation file. Problem : after simulating results my answer can't match with that thesis. How can I validate that research paper for better understand of drilling operation in ansys explicit dynamic

September 13, 2020 at 3:15 pmpeteroznewman

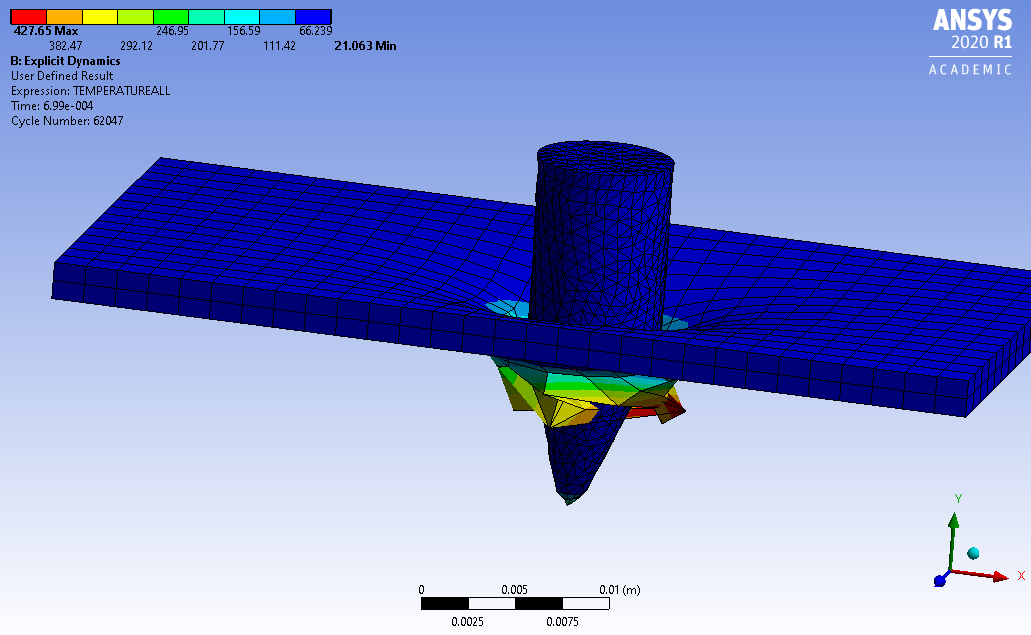

SubscriberValidation occurs when you compare your simulation result to an experimental measurement.nYou are not doing validation. The research paper did no validation.nYour model is wrong because you used a Fixed Support on all six faces of the work piece. You should only fix the four edge faces.nYour model is wrong because you have zero friction in the Body Interaction. You need a non-zero friction to create heat.nYour model is wrong because you used a Remote Displacement on all seven faces of the tool. You should only use the top flat circular face.nYour model did not change the Erosion Controls from Strain to Material Failure. If you do those things, this is what you will get...n I don't think the research paper produced a result that would match any experimental data. The mesh is too coarse and they only used 2 elements through the thickness of the work piece.n

September 13, 2020 at 7:25 pm

I don't think the research paper produced a result that would match any experimental data. The mesh is too coarse and they only used 2 elements through the thickness of the work piece.n

September 13, 2020 at 7:25 pmMAMIN219

SubscriberRespected sir, Thank you for your kind reply. According to your guidance I have tried simulation once again but There is huge difference in value Or Equivalent Stress ( von-mises) I am getting close answer for only total deformation. Can you please guide us for other parameter so that we can get very close in our answer according that paper.Also can you please tell me Erosion Controls from Strain to Material Failure in brief for better understand. nAnd also How can I find temperature profile for tool and workpiecennSeptember 13, 2020 at 10:44 pmpeteroznewman

SubscriberMy advice is to not spend time trying to get your model results to match the results from that paper, which did not do a mesh refinement study. I don't find any scientific value in that paper. I recommend you find a research paper with a simulation result validated against actual experimental measurements including statistics on the variation about the mean.nThe default Erosion control in Explicit Dynamics is the element fails when the strain reaches 150%, which is an arbitrary value used for any material. That is not at all relevant. You have a material model that has a failure criterion built-in that has been validated against experimental measurements. That is much more relevant.nSeptember 14, 2020 at 5:04 pmMAMIN219

SubscriberWhat about user defined Function in explicit dynamic. Like if I am trying to perform this whole drilling operation and after simulation I am Adding UDF with TemperatureAll command. Is this correct way to find out temperature profile for this operation Or are there any other approach for finding suitable temperature for drilling and other operation. nThank youn Mihir AminnSeptember 15, 2020 at 1:20 amNovember 9, 2020 at 12:10 pmMAMIN219

Subscriberrespected sir, I have applied all things with your guidance. I have doubt in analytical end time calculation for drilling operation .Can you please tell explicate ndynamics end time calculations for 285 RPM Spindle sped .nI am also attaching my ANSYS file in which time step error is there because I have doubt in end time calculations. nAlso how can I find thrust force in this drilling operation.nnNovember 12, 2020 at 9:31 amMiner

SubscriberI am working on the cutting simulation. My experience is before the parametric study, we should do mesh sensitivity analysis first. When the mesh siez effect is ruled out, the subsequent parametric study could be reliable.nNovember 14, 2020 at 1:21 pmMAMIN219

Subscriberrespected sir, Please give your valuable feedback on my file and please tell how can I find end time for drilling process.nnwith regards,nMihir AminnViewing 8 reply threads- The topic ‘Regarding Drilling operation in ansys explicit dynamic ( Validation of research paper)’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5094

-

1830

-

1387

-

1248

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.