TAGGED: #fluent-#cfd-#ansys, fluent

-

-

January 30, 2026 at 6:51 pm

yhgeng

SubscriberI am currently working on a project involving the simulation of a centimeter-scale, screw-driven robot. My primary goal is to accurately model its locomotion and find its equilibrium state as it moves through water.

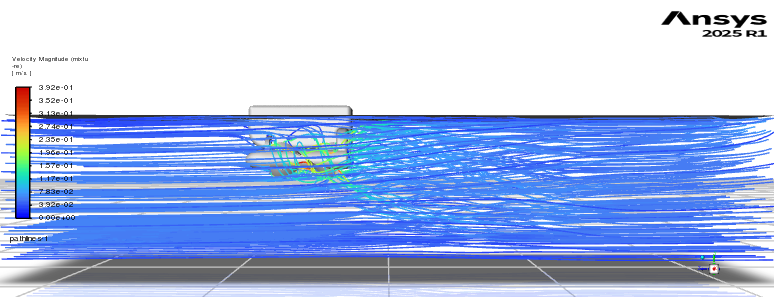

Initially, I attempted to solve this using a steady-state simulation approach to save on computational costs. However, I’ve encountered issues that the forward velocity (equals the water velocity when the net force = 0) (As shown in Image 1) deviates quite a lot from the tests in real life. And also I need to set different velocity of water manually to try to find the equilibrium state (through parametric study).

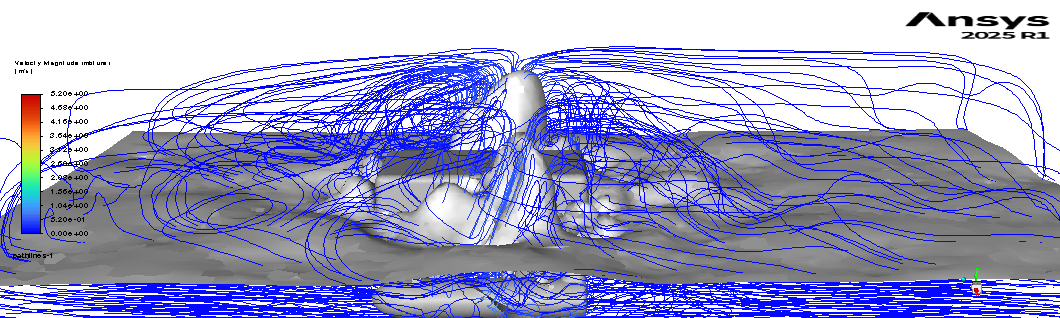

I have now switched to a transient state simulation to better capture the time-dependent nature of the fluid-structure interaction.(Image below, I don't know why this weird spike happened, I will need to debug it). While this provides more granular data, it is significantly more computationally expensive and makes finding a definitive "equilibrium state" (where thrust equals drag) a challenge (Same challenge as the steady state simulation).

Questions for the Community:

Is 6DOF (Six Degrees of Freedom) necessary? Given the screw-driven nature of the robot, would implementing a 6DOF solver be the most reliable way to let the robot "find" its own equilibrium velocity and orientation, or is it overkill for a centimeter-scale model?

Finding Equilibrium: If I want to stick with a standard transient or steady state approach, are there proven methods or specific monitor points I should use to efficiently identify when the system has reached equilibrium without running excessively long physical time scales?

Best Practices: For those working with screw-propulsion in multiphase environments, are there specific solver settings or mesh motion strategies you would recommend to balance accuracy with solve time?

Thank you for your time!

-

- You must be logged in to reply to this topic.

-

5009

-

1681

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.