-

-

January 16, 2026 at 1:51 pm

parth.shingte

SubscriberHi all,

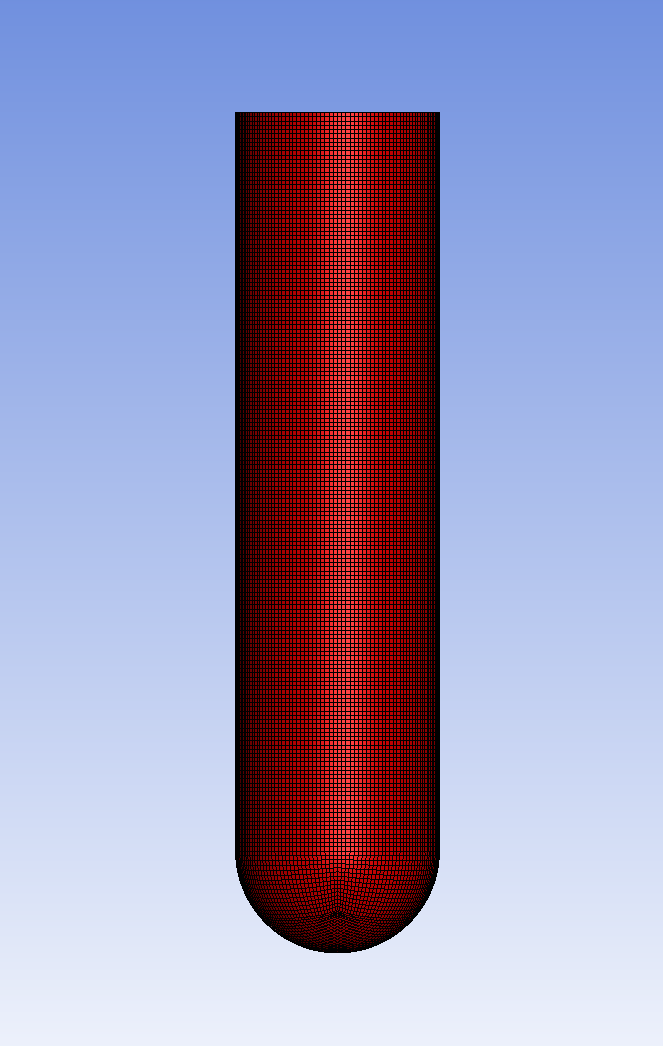

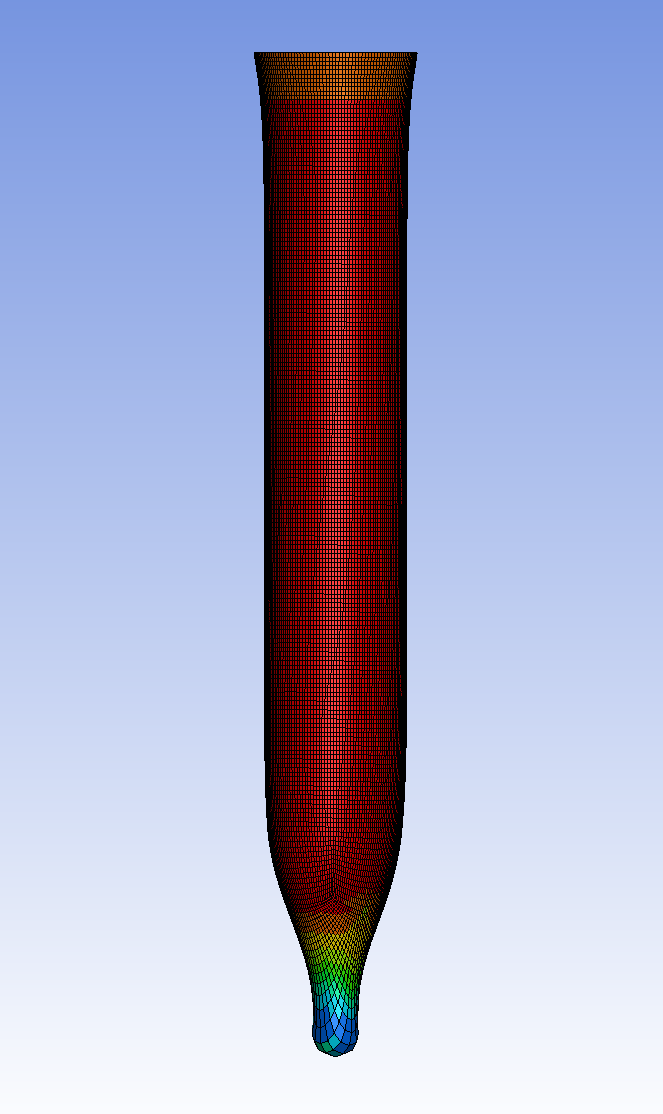

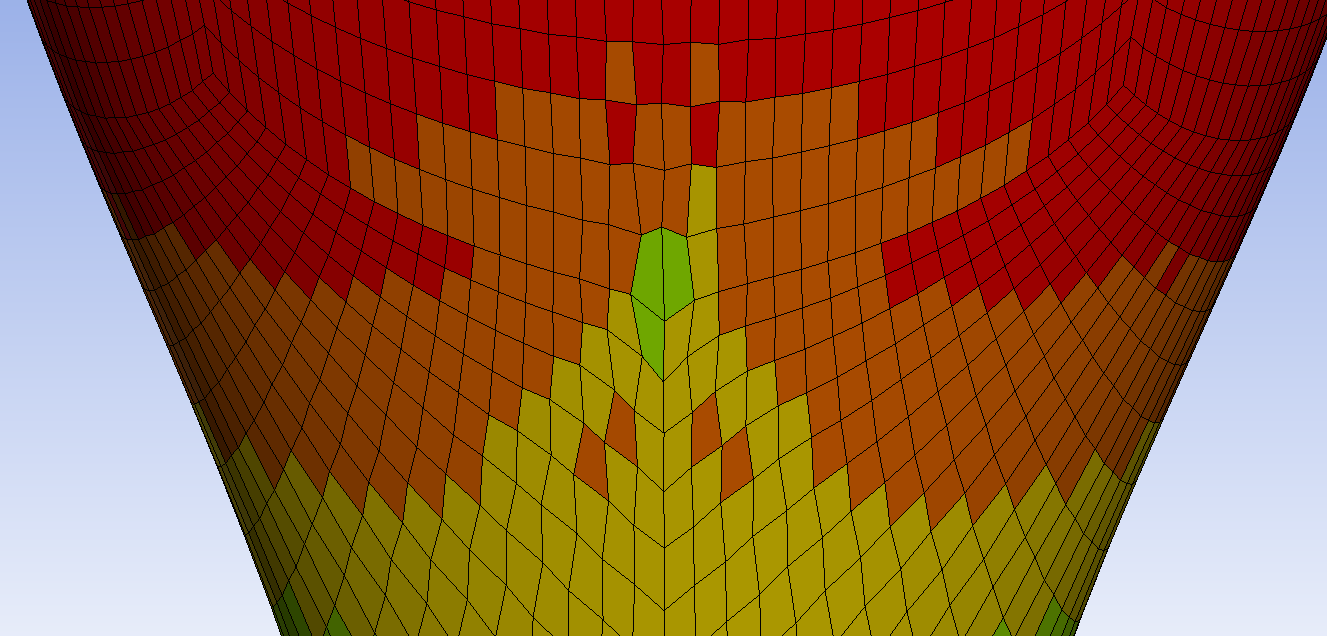

I am working on simulating an injection stretch blow molding (ISBM) process. The contact rod and the mold are modelled as rigid bodies. Contact rod is provided with the prescribed rigid body motion and assignes a velocity curve. Contact automatic surface to surface is used for all contacts. I am using MAT77-H to model the visco-hyperelastic behviour of Polyethylene Terephthalate (PET) preform. During the stretching part of the process i have large uniaxial strains. The geometry is modelled using shell elements (ELFORM 2 for the preform). I am using ihq = 1 for hourglass control. I tried several values for the hourglass coefficient from 0.1 upto 0.35 and i can observe least hourglassing at QH = 0.35. But such a high value is adding a lot of artificial stiffness at a few elements which are near the contact region between the contact rod and the preform. Even with this value some elements are still showing hourglass modes.

When i apply pressure after this step using load segment on the preform, it initially expands but then the elements at the contact region and a few neighbouring elements fail and are deleted.

-

January 16, 2026 at 2:38 pm

ErKo

Ansys EmployeePerhaps use adaptive remeshing.

All the bestErik

-

- You must be logged in to reply to this topic.

-

4969

-

1645

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.