TAGGED: 2d-axisymmetric, apdl, archard-wear-model, contact

-

-

January 15, 2026 at 11:48 pm

peteroznewman

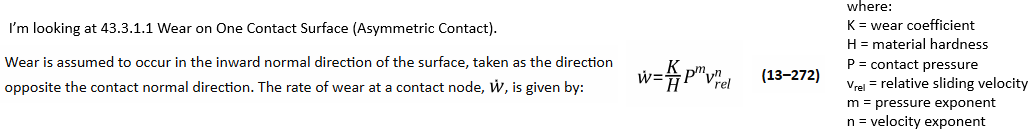

SubscriberI downloaded and solved Tech Demo Chapter 43 to explore the Archard wear model to see material removal as a function of the wear constant K, material hardness H, contact pressure P and sliding velocity.

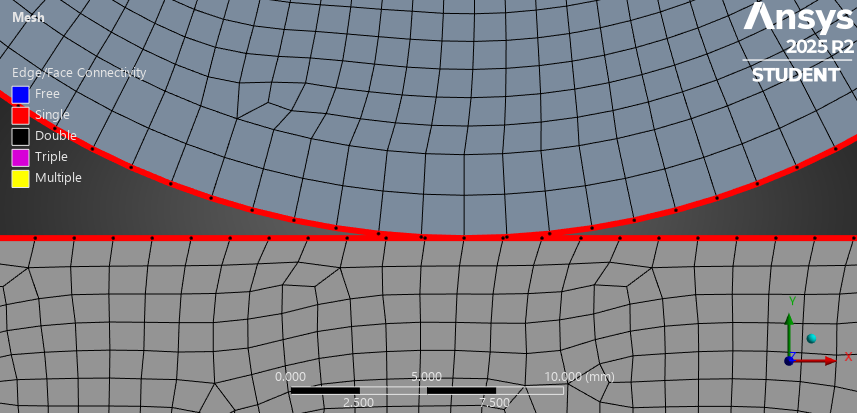

I ran the TD43 (as is) which is an Axisymmetric model that includes Nonlinear Adaptive mesh code to automatically remesh the body when the element height is cut in half by wear. The analysis is a two-step simulation with a compression force applied in step 1 where no wear occurs, while in step 2 the wear process occurs as a linear function of time in this static structural analysis.

Experimentally, test sample surface profiles are measured before and after wear operation using an optical profilometer. The profilometer software calculates the wear volume and wear depth from the acquired data. Therefore a direct comparison between experimental measurements and simulation results would be wear volume and/or wear depth.

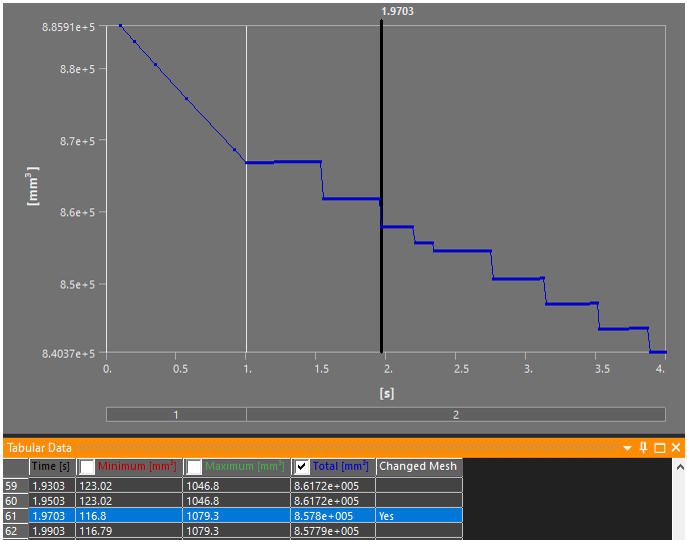

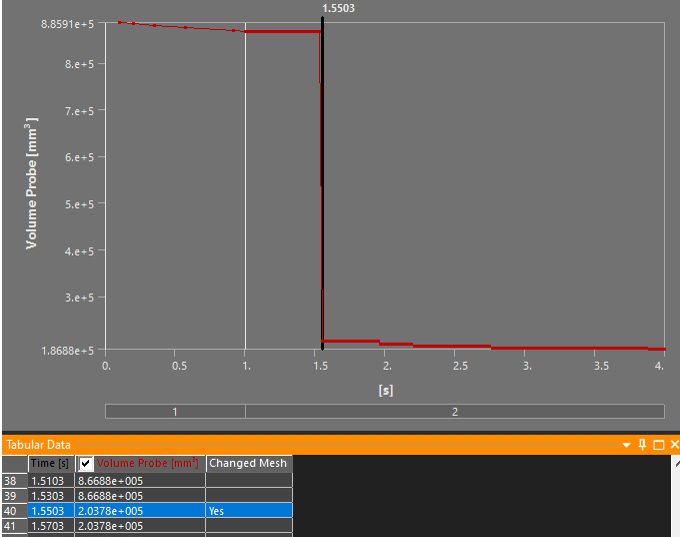

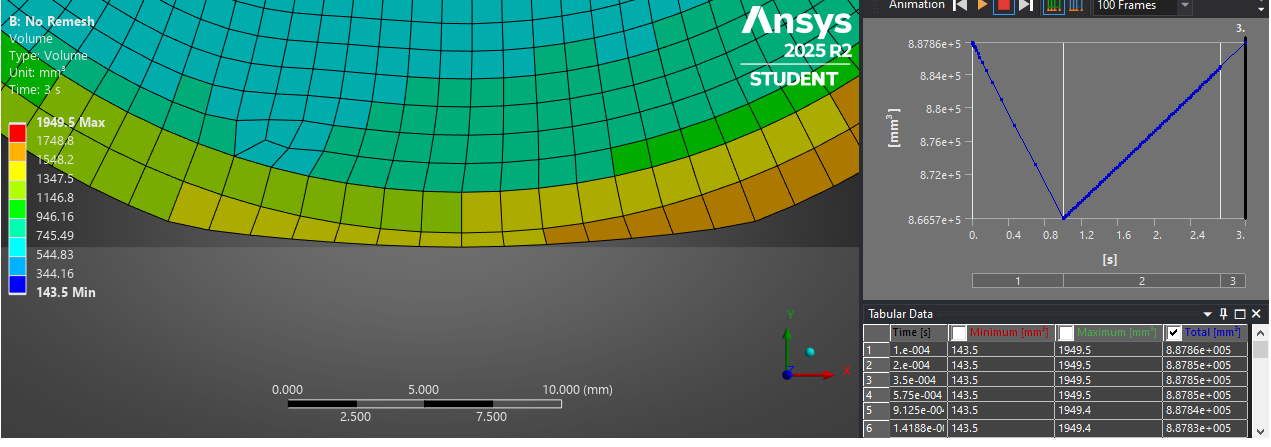

I added two results to the simulation: a Volume result and a Volume Probe on the copper body and assumed Wear Volume = Initial Volume – Final Volume.

Volume Result

Step 1 showed a linear reduction in volume as the compressive load ramped on then a stair-step reduction in volume upon each remesh. Between remesh events, the volume increases slightly which is odd.Volume Probe Result

A large and sudden change in the Volume Probe happens when the first NLAD remesh occurred. Why does that happen?

Quick Test

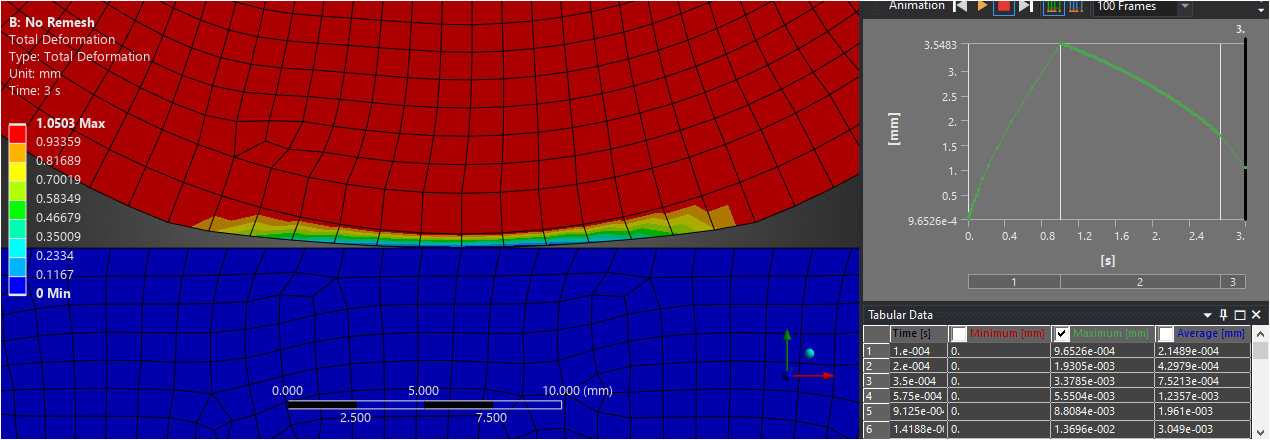

I suppressed the Nonlinear Adaptive mesh code, changed the End Time of Step 2 to 2.77 s which is when the first layer of elements wears down to a thin element height and added Step 3 to ramp the compression force down to zero.

From the Total Deformation at the end of step 3, the wear depth at the center is seen to be 1.05 mm.

Now the increase in Volume during wear in Step 2 is easily seen and furthermore, the volume after unloading is equal to the volume at the start of the simulation!

Why does the volume increase when the elements are getting thinner? What is the correct way to measure wear volume?

-

- You must be logged in to reply to this topic.

-

4974

-

1650

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.