-

-

December 28, 2025 at 1:13 am

asher.vanderdeen

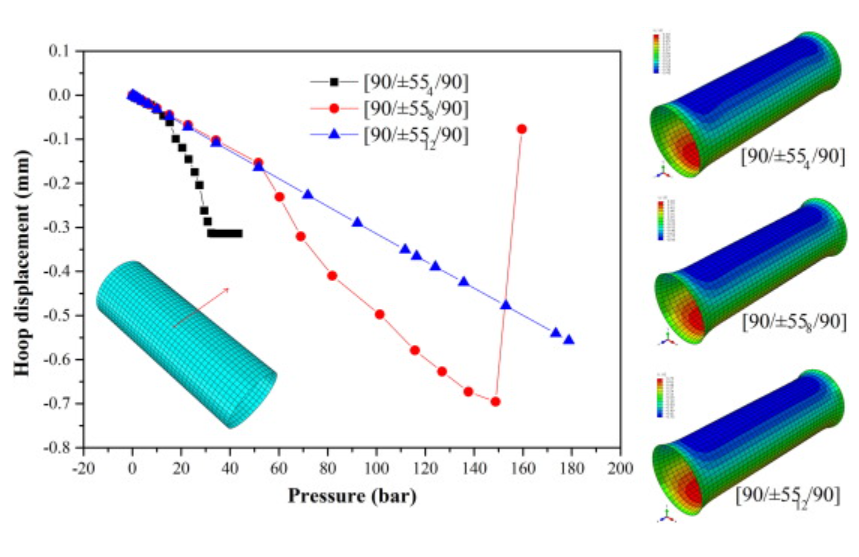

SubscriberI am trying to copy a simulation or model from a research paper https://www.sciencedirect.com/science/article/pii/S0264127516302003 Damage and failure in carbon/epoxy filament wound composite tubes under external pressure: Experimental and numerical approach. I am doing this so that I can confirm that I am properly able to use ANSYS Mechanical or specifically ANSYS ACP. I am trying to simulate a composite pressure vessel under external pressure. I am on a student engineering team and have full access to ANSYS and am doing this to confirm that I can match a proven experimental model so that when I move to the real project, I can have more confidence it wont explode. I have no education or real training for ANSYS so I will try to give as much info as possible. when i first tried to up load this it wouldnt let me because my image files were too long so i will try submit them after this.

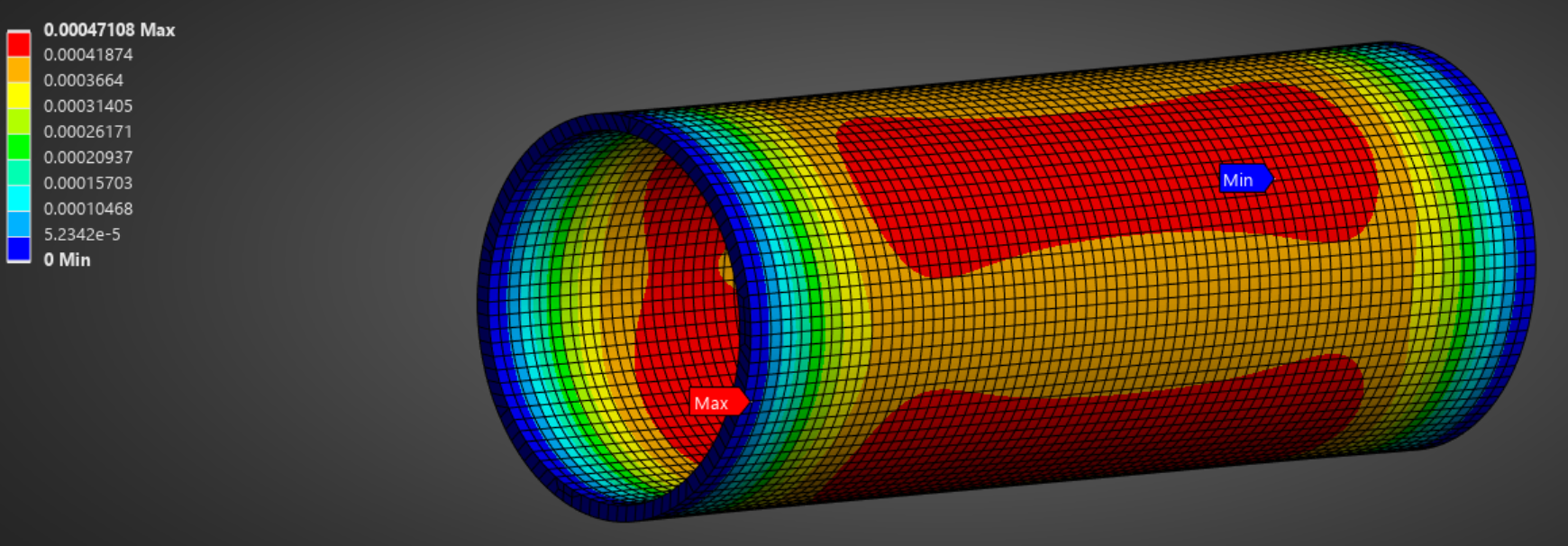

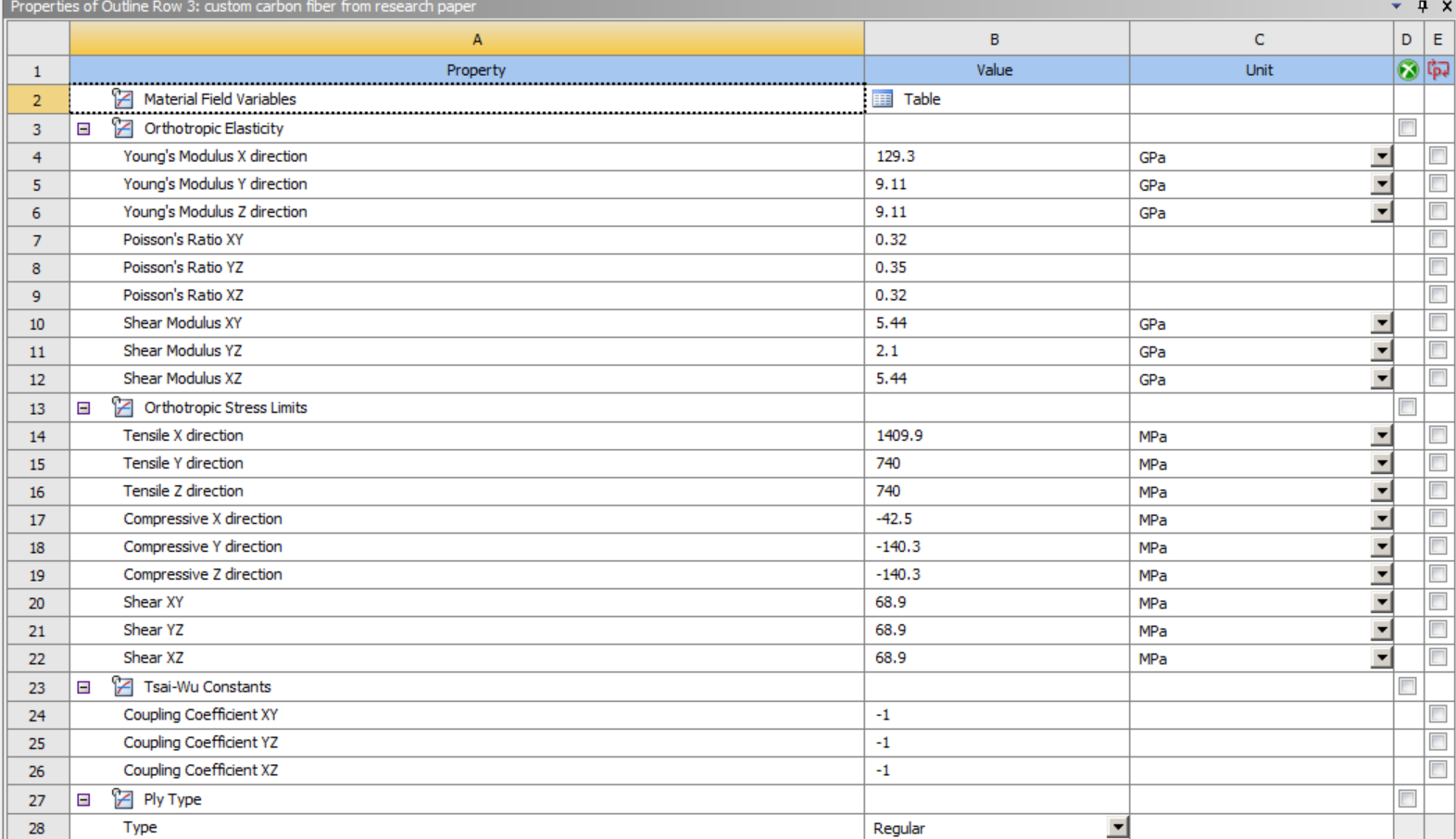

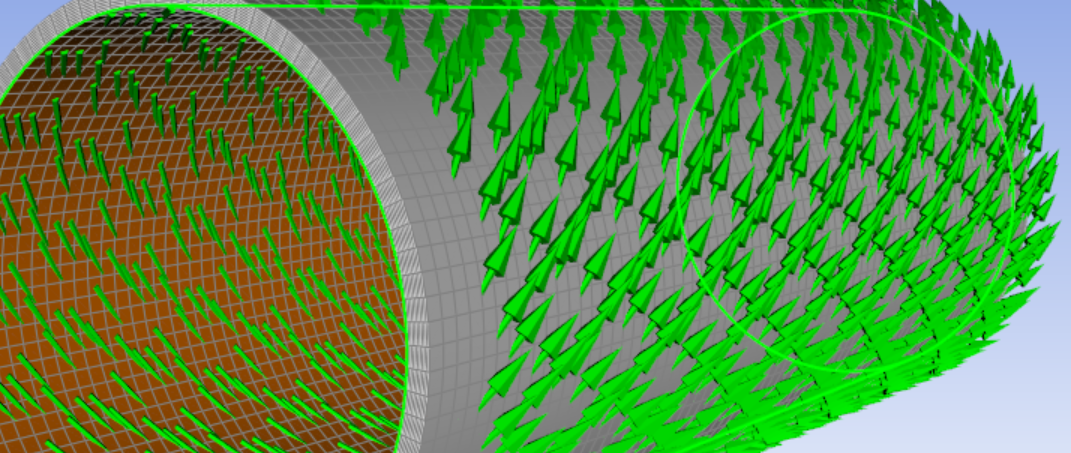

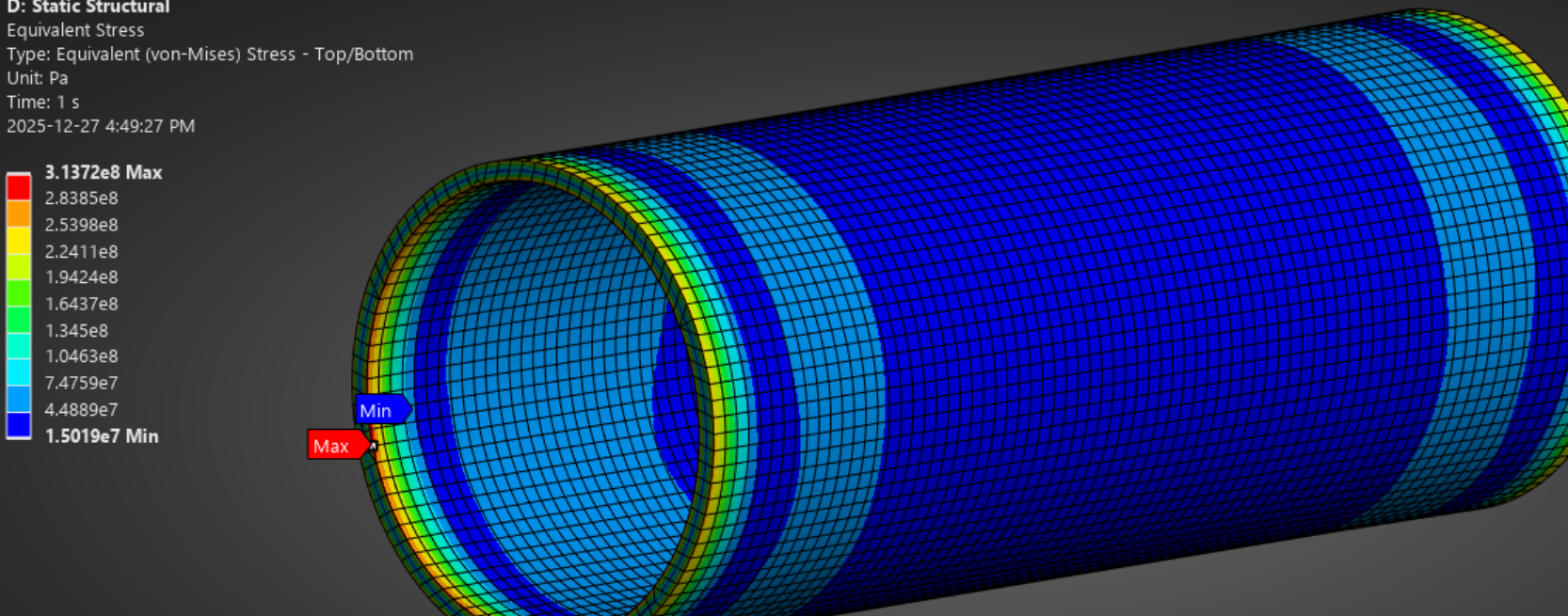

My model is not radially symmetric and the paper does not show anything like my results in terms of deformation. You can see the red areas aligned perfectly with the x and y axis. My two theories for this are: material has something wrong with it since the strengths are determined in the x, y, and z directions so instead of following the proper ply it just makes it one hunk of orthotropic material; second theory, I have done something wrong with the ACP (pre) Setup. I can't find any issues but I can imagine if I made some mistakes with the ply it could make unusual stress concentrations. I have 10 layers in [90/±55/8/90] arrangement. I have given an image of it.

The model doesn't have the same strength as the one in the paper. The paper has a graph of pressure vs hoop displacement. I looked at that then compared the maximum displacement of the ANSYS model with the paper and they disagreed. It should be in the linear region at 37.5 bar. The paper has 0.1 mm as the displacement and mine was 0.47 mm.

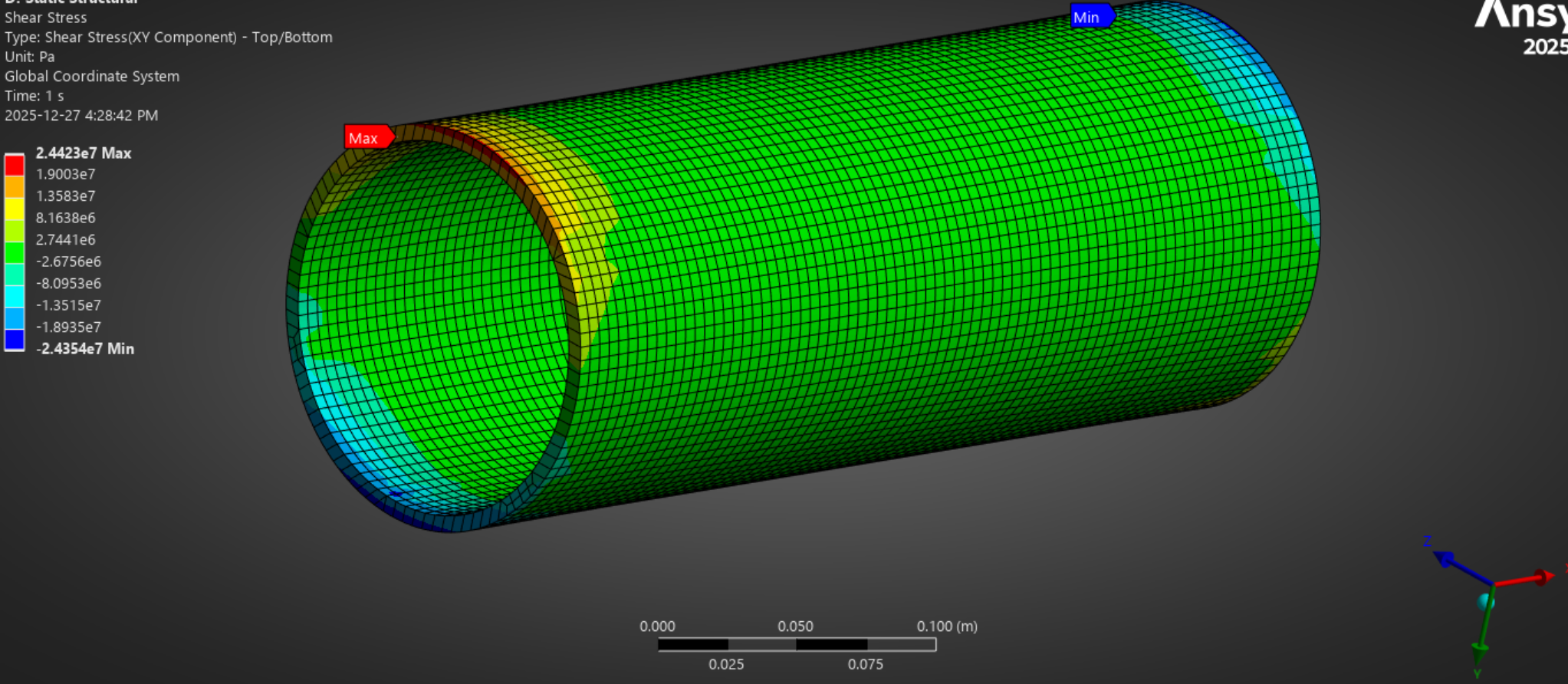

Many of the solutions I have give very unusual results. I can give more of them if needed but like say the shear stresses look weird. Everything about the model is radially symmetric, yet near the ends it has large opposite shear like pictured. The actual stress looks pretty normal like it is radially symmetric even if slightly weird. This makes me think that it is the material that is causing the weird deformations that don't look like the paper.

I understand that there are many issues. I just tried to give the broad strokes of what would help for diagnosis. Please ask if you need more details. Thank you for helping me and have a wonderful holiday season.

-

December 28, 2025 at 1:14 am

-

December 28, 2025 at 1:15 am

-

December 28, 2025 at 1:18 am

-

December 28, 2025 at 1:19 am

-

December 28, 2025 at 1:21 am

-

December 28, 2025 at 1:22 am

-

- You must be logged in to reply to this topic.

-

4683

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.