-

-

December 4, 2025 at 8:38 pm

johannes.bauer

SubscriberHello, I'm no beginner to Ansys static-structural analysis. However I recently stumbled upon a rather odd behavior of a model I created including frictional contacts. I couldn't explain why the model behaves like this and therefore I decided to post my first forum entry. I am working with version 2025R2.

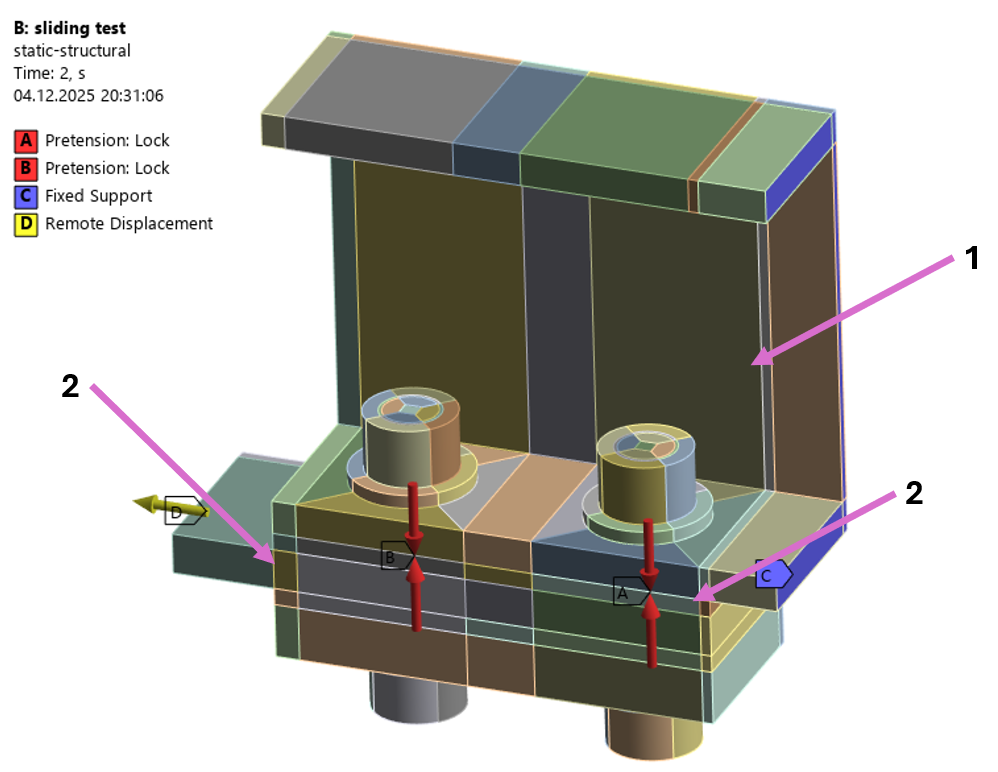

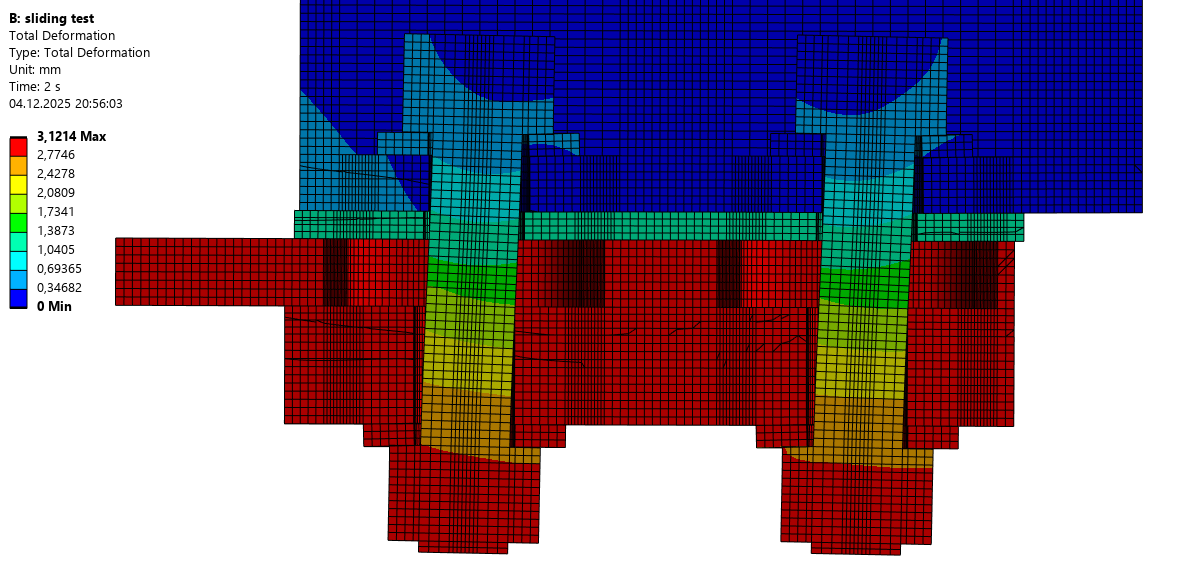

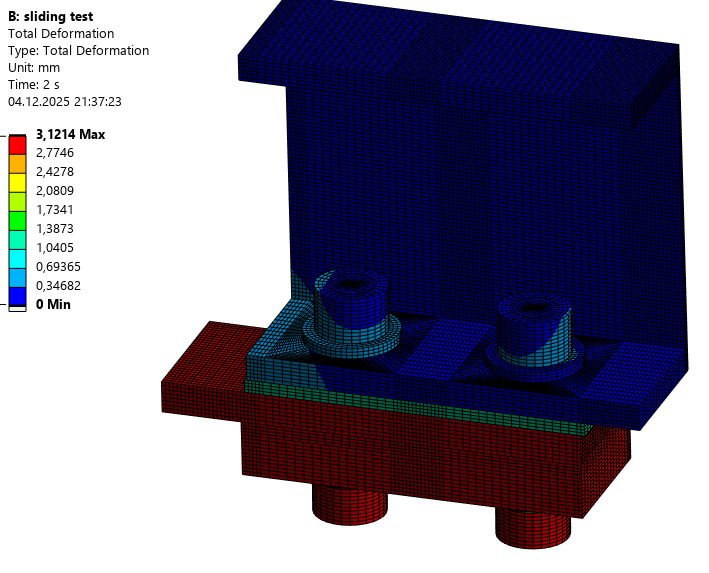

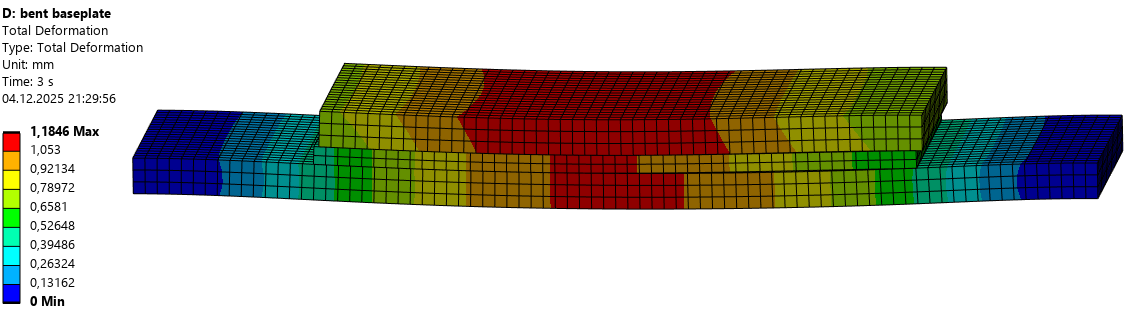

The setup is as follows: I have several plates (all defined by frictional contact on the interfaces to each other), which are bolted to a beam (1). The bolts are pretensioned in the first load-step. In the second load-step I apply a displacement of 3 mm to the middle plate (2). I use the direct solver with large deflections turned on. Please see the figure below concerning boundary conditions. The mesh consists of linear solid hexahedrons. The model is symmetric, hence I employed a symmetry region at the back of the beam (1). The model has good convergence and does not yield any concerning warnings or errors. The model is validated by checking contact forces and balance of forces.My question is regarding the behaviour of the sliding of the middle plate (2) between the beam (1) and the plate that is displaced by the boundary condition (3). The plate is sliding on both contact surfaces and when reviewing the displacement I can see that this is true. Also the frictional force reached is consistent with the normal force following couloumb's law. It stays constant during sliding. Also I should mention, that the displaced plate has slotted holes instead of conventional bolt holes, as can be seen in the results of the total deformation in the next figure with the section plane.

As I already mentioned, the middle plate is sliding and is in fact not yet in contact with the bolt shaft. And that is my question: Why does it not perform rigid body motion? When sliding, the plate moves independently, as suggested by the color grading. Also I checked the contact status on both surfaces. There is no sticking. When first looking at the results I was satisfied, since testing of similar setups have shown this kind of sliding behavior in the real world. But then I got confused about how a static analysis should work. There is no inertia present and therefore, when the plate is sliding there should be no stopping it. I know this error, when a model is not constrained properly. It usually yields solver errors and the total deformation shows rigid body motion. Why is this not the case here? (Also I should mention that weak springs are turned off, so this can't be the reason.)

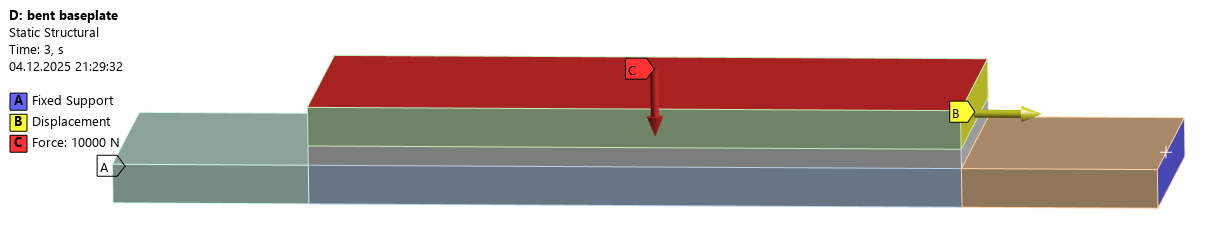

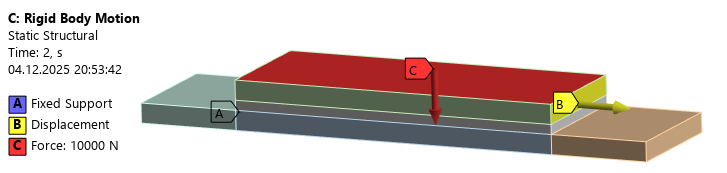

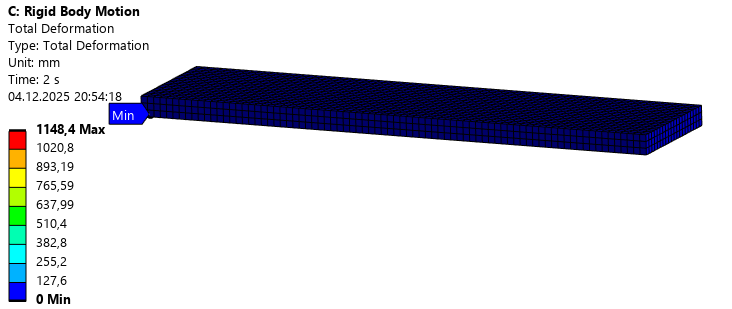

So I got curious and set up an even simpler model as presented in the next figure. Here I see what I would expect: The rigid body motion, since the middle plate is only constrained by the two contact surfaces.

Is it because of the infinite stiffness of the fixed support? I also tried this, but here there is no sliding between the middle shim and the bottom shim. Probably because the slid the middle plate has to pass through is narrower than its thickness due to the bending and therefore stays put. So this also doesn't reproduce what I am seeing in my main model.

So if someone can provide any insight on why my model works (which I am glad about :D) I would greatly appreciate it. Thank you in advance.

Kind regards

-

- You must be logged in to reply to this topic.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

- Test post on Forum – LLM response – SC

- 13-Node Pyramid Element Shape Function

- Element Birth and Death

-

4452

-

1494

-

1376

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.