-

-

November 3, 2025 at 9:14 am

SR786

SubscriberHello,

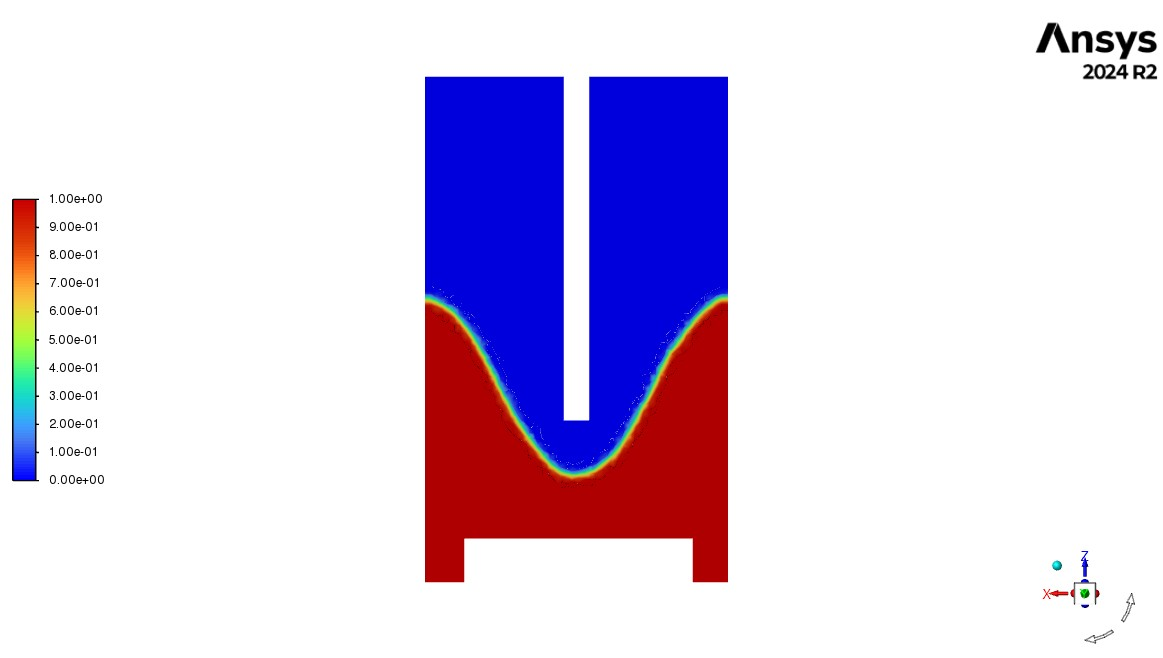

I am modelling an unbaffled stirred reactor in ANSYS Fluent where I am simulating semi-batch feeding. I initially used the homogeneous VOF framework to track interface between air and water (no feed, only considered batch mode of operation) and got a converged solution. Next I activated species transport equation and used mixture template with 3 species (water, calcium ion and oxalate ion). The oxalate ion is pre-charged in vessel and was therefore patched with concentration 0.04 M. The calcium ion was fed from feed pipe (positioned above vortex) at 4 L/h and 0.04 M with 2 L being added to vessel. There should be no discharge of material and there is no reaction. What I am noticing is that for the pre-fed species (oxalate) the mass (computed from mass integral of mass fraction of oxalate) seems to be continuously increasing despite there being no specified inlet flow for this species (I have double checked all boundary conditions) after short period of process time 0.74s. Mass increase reported from 0.0069274 kg to 0.0069328 kg which would lead to wrong transient behaviour as dilution effect isnt captured due to volume increase. I have tried adjusting time step size and URF to check the effect it would to no avail. The residuals look good as they are decreasing to < 10^-5 at each time step. It is only this artificial increase in mass of oxalate. I have attached some images below of geometry, mesh and vortex shape.

This is my set-up:

Solver: Homogeneous VOF (Implicit)

B.C: Veloicty-inlet (mass fraction of oxalate = 0), pressure outlet (backflow volume fraction of air = 1, mass fraction of species = 0), No-slip (0 mass flux)

Discretisation: Green gauss node based, compressive (volume fraction), second order upwind

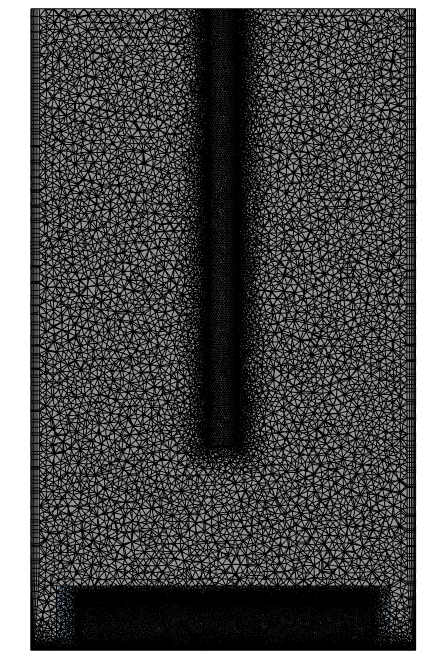

Mesh: Unstructured tetrahedral ~ 2 million cells

URFs: 0.3

Timestep size: CFL < 1

-

November 3, 2025 at 3:46 pm

jcooper

Ansys EmployeeHi:

It sounds like your timesteps and residuals are quite low, but if the species accuracy that is required to honor the mass balance translates to a tiny massfraction amount, ie: 1.0e-06 and lower, the residual criteria you are using may still not be strict enough. Transient error is unfortunately additive, so species solutions that run over long flow times can be quite sensitive to this type of error buildup.

How is the species mixture density being handled? If the species are dilute with water as the carrier fluid, make sure to change the species mixture density from the default incompressible ideal gas treatment to a weighted density formulation after creating it. (Ideally you should also use weighted mixture rules for the other mixture properties to reflect the changing nature of the mixture, especially molecular weight.) Note that capturing these property changes in a very dilute mixture will also require very sensitive residual criteria.

Another factor may be the mesh. If this is an axisymmetric problem with lots of solid body rotation in the flow, then a rotationally-swept hexahedral mesh will generally perform better. Tetrahedral meshes tend to be more diffusive than hex meshes, with the result being that gradients get smeared out. This can also contribute to mass losses in VOF cases. Before committing to a hex mesh, which can take longer to generate, I would suggest trying a radical mesh refinement like 2x finer to see if the mesh is a factor here. (In the grid-independent limit, hexes and tets should perform the same, but a lot more tets are often required for this than anyone realizes.)

Regards,

Judy

-

November 3, 2025 at 3:58 pm

SR786

SubscriberHi,

Thank you for the reply. I am using weighted mixture for density and viscosity. I have refined the mesh further and ran a simulation but the same effect occurs. I have also tried turning off the feed and just patching initial concentration of oxalate in domain but the issue still persists in terms of mass accumulation

Changing mesh type from tetrahedral to hexahedral will be unfeasible for me as I am a PhD student and my previous work over the past 2-3 years (hydrodynamics, batch mixing) has involved using tets on domain.

-

November 3, 2025 at 4:15 pm

jcooper

Ansys EmployeeHi :

Where are the outlets in your simulation? Is this an axisymmetric geometry what you are solving? Also, what are your exact bounday conditions in terms of velocity, pressure, mass fraction and temperature (inlet and outlet)? Are you getting any backflow messages for the inlet or outlet?

I am also curious how you are imparting rotation to the flow? Is this via a moving wall, or are you solving in the rotating frame?

-

November 3, 2025 at 4:25 pm

SR786

SubscriberHi, this is a semi-batch reactor so there are no outlets to remove liquid. Instead liquid level rises with respect to time. At the top is a pressure outlet condition which allows removal of air as it replaced by liquid mass fracions of species are set to 0 here. The pipe inlet is set using a velocity inlet boundary condition, mass fraction of calcium ion is set to 0.0016 and mass fraction of oxalate ion is set to 0. Rest of tank B.C are walls with no-slip. The case is isothermal. I am solving full 3D cylindrical geometry (image is shown of 2D plane)

-

November 3, 2025 at 6:20 pm

jcooper

Ansys EmployeeWhat is producing the shape of the liquid surface? Is there rotation?

-

November 3, 2025 at 6:58 pm

jcooper

Ansys EmployeeIf the liquid level is rising, then I would expect there to be an accumulation. Maybe the accumulation of the specie is coming from an issue with one of the other species, since they all must add to 1.0? What is your constraint specie? I would use the water, so that you can offset the significant digits required for the small mass fractions. I would also solve with double precision and the coupled pseudo transient solver rather than SIMPLE (segregated) methods.

-

November 3, 2025 at 8:14 pm

SR786

SubscriberThe free surface shape is produced by rotation of magnetic rod stirrer (multiple reference frame). The two liquids that are mixing are aqueous solutions composed of water and dissolved ions. Feed pipe contains calcium ion and water (no oxalate). Bulk liquid in tank contains oxalate ion and water initially (no calcium ion). I am unsure of what you mean by constraint species? The solver is solving for N-1 species, so calcium and oxalate ion are being solved (though there are 3 species in the liquid phase including water). I am using double precision mode in fluent and SIMPLE algorithm in transient mode. Accumulation should not occur as oxalate ion is not being consumed or removed. What should happen instead is dilution where as liquid volume is increased and assuming mass stays the same then the concentration of oxalate ion in the tank should decrease. The accumulation of mass for oxalate masks dilution and is physically unrealistic.

-

November 3, 2025 at 10:18 pm

jcooper

Ansys EmployeeIt sounds like your constraint specie (the one not solved) is water, which is a good choice.

If you add no calcium, and just stir the solution, does the oxalate remain constant?

If the calcium mass fraction is initially zero and gradually rises, the accuracy required at the beginning of the calculation will be larger than later on. The residual targets should account for this. RMS Residuals are deceptive because they don’t tell you much about areas that may still be unconverged at the end of a timestep. Monitoring the calcium mass fraction in a few key areas should tell you if you are truly reaching convergence or if the mass fractions in those locations are still trending near the end of a timestep. (You could monitor total mass of calciumat each timestep iteration, which will make any nonconvergence easier to detect.)

Some simulations require the incoming specie to be injected via a volume source to reduce the species gradient at the inlet, as well as mesh refinement at the species inlet. If you find that calcium is disappearing, then this strategy may work for your case.

-

- You must be logged in to reply to this topic.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Issue to compile a UDF in ANSYS Fluent

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

-

4167

-

1487

-

1363

-

1194

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.