TAGGED: dpm, periodic-boundary

-

-

October 14, 2025 at 8:49 pm

sjohn

SubscriberMy case is similar to Chapter 2: Modeling Evaporating Liquid Spray in the Ansys Fluent Tutorials, with the following notable exceptions.

- Instead of a an air-blast atomizer, the injection is performed using a pressure swirl atomizer.

- Periodic boundary condition: Instead of 30-degree wedge, my case has a 22.5 degree wedge as the domain.

- Instead of swirling air, air is introduced parallel to the main axis.

For the pressure swirl atomizer injection properties, I have specificd the azimuthal start and end angles as 0 and 22.5 degree. Despite this, the display shows a 360 degree cone and the droplets are sprayed outside the domain (22.5 degree wedge). When I run the case, I also get an error saying the droplets were sprayed outside the domain. -

October 15, 2025 at 9:05 am

Rob

Forum ModeratorThe injection display is "dumb" in that it's just a graphic and doesn't reflect any angle settings - it's an aid to make sure you've got the injection in the right place and point in the right direction. Assuming the sector modelled is 0 to 22.5 degrees and not 90 to 112.5 or similar try reducing the band to 0.5 to 22.0 and see if that changes. Any parcels that miss the domain are automatically fail. It should be a warning rather than an error, and should also show a fraction of mass/parcels that are missing.

-

October 15, 2025 at 2:38 pm

sjohn

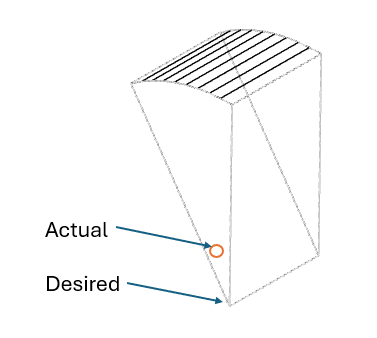

SubscriberI was able to solve this issue by moving the injection point slighly into the domain. Initially, I had set the injection point at one of the vertices of the wedge but it gave me the warning (as mentioned in my first post). When I ran the case after moving the point into the domain, it did not give me a warning but the position of the injection point does not accurately represent my test article because it is not at the vertex (desired) but inside (actual) as shown in my schematic below.

-

October 15, 2025 at 2:42 pm

Rob

Forum ModeratorIf it's precisely on the vertex it may be "outside" due to rounding effects. You should be fine if it's a tiny amount into the first wedge cell. I've seen similar problems on circumferential injections where the defined point is on the curved face but fractionally outside the faceted representation of the curved face.

-

October 15, 2025 at 3:22 pm

sjohn

SubscriberThe issue with my current apporach is that it models an injection point in one wedge, which due to the periodic condition causes there to be multiple injection points. In reality there is a single pressure swirl atomizer at the center (vertex), which sprays fluid into each wedge. This should be a common scenario, wonder how is such a case setup.

-

October 15, 2025 at 3:59 pm

Rob

Forum ModeratorIf you set the injection with a full 360 cone what happens? Make sure you've got more than 64 streams to ensure there are no half-angle effects for parcel injection placement.

-

October 15, 2025 at 11:34 pm

sjohn

SubscriberMy guess is that an injection with a full 360 degree cone would give warning similar to the case in which the injection point was at the vertex and the cone was 22.5 deg (difference between azimuthal start and end angles).

I am using 16 streams total because there are 16 sectors (wedges) of 22.5 deg in reality. I figured it would be good to have only one stream in each sector/wedge. The flowrate specified by me in Injection Settings/Point Properties is 6.88e-05 kg/s.

Can you explain the significance of 64 streams?

-

- You must be logged in to reply to this topic.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- Issue to compile a UDF in ANSYS Fluent

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

-

4077

-

1487

-

1318

-

1156

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.