TAGGED: #fluent-#ansys, #multiphase_models, fluent-dpm, spray

-

-

August 29, 2025 at 9:33 am

makarand.srinivas24

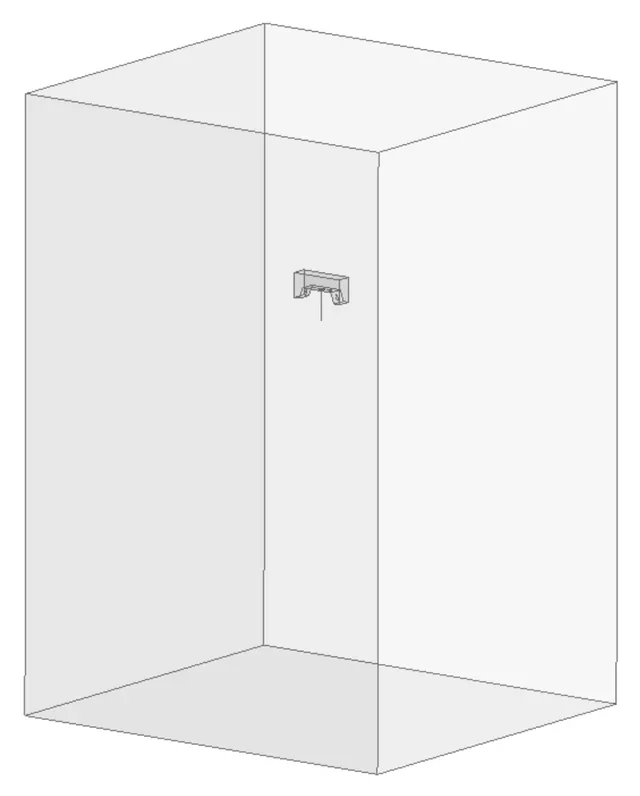

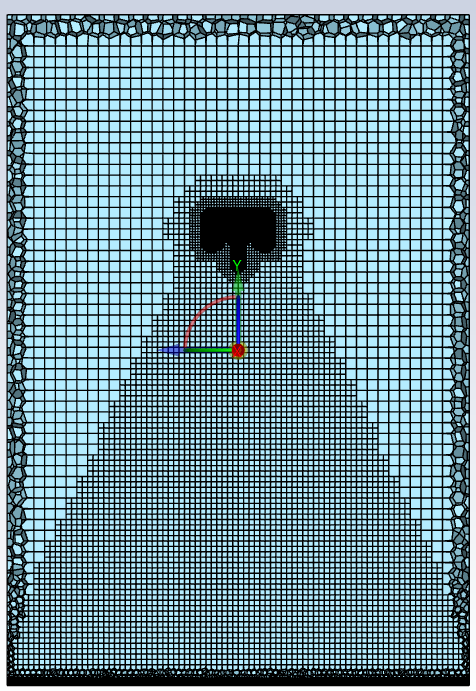

SubscriberI am conducting a CFD analysis of the Electrostatic spray coating process in ANSYS Fluent, and I am currently facing an error of floating-point exception (image 1) after 8.5 hours of runtime. As there are many parameters to tweak, I'm getting confused about what to change now.

The following are the details of geometry and boundary conditions:

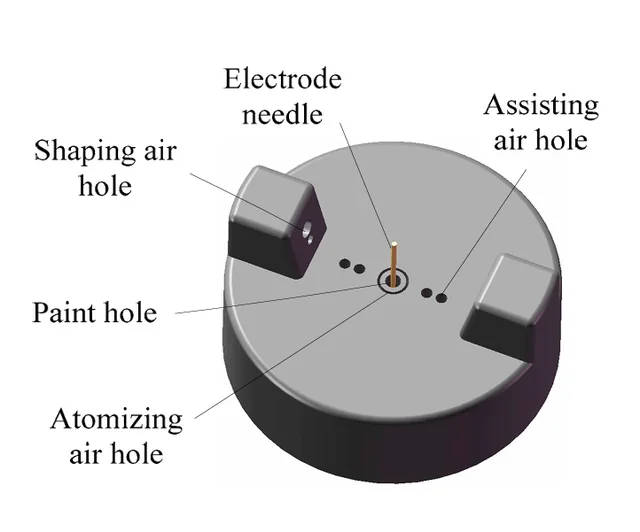

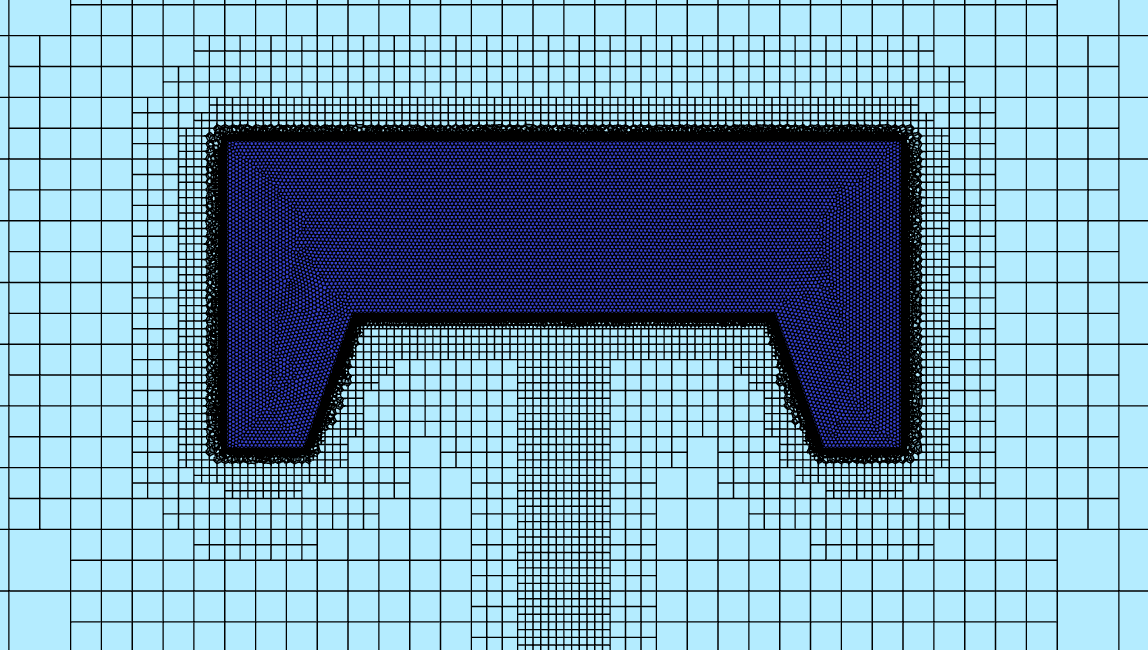

Geometry (image 2): domain of 0.3 x 0.3 x 0.4 m. The distance from the spray nozzle tip to the substrate (plate to be coated) is 0.25m.

Models used:

Multiphase > Dense discrete phase model > Phases: 2 - Air (Primary phase), Paint (secondary phase).

Turbulence model > SST k - omega

DPM > interaction with continuous pahse>ON

Injections> ring cone type (inert particle)> velocity=18m/s, mass flow rate=0.0132kg/s, particle mean dia=65 microns distribution pattern: Rosin ramler

Potential > ON

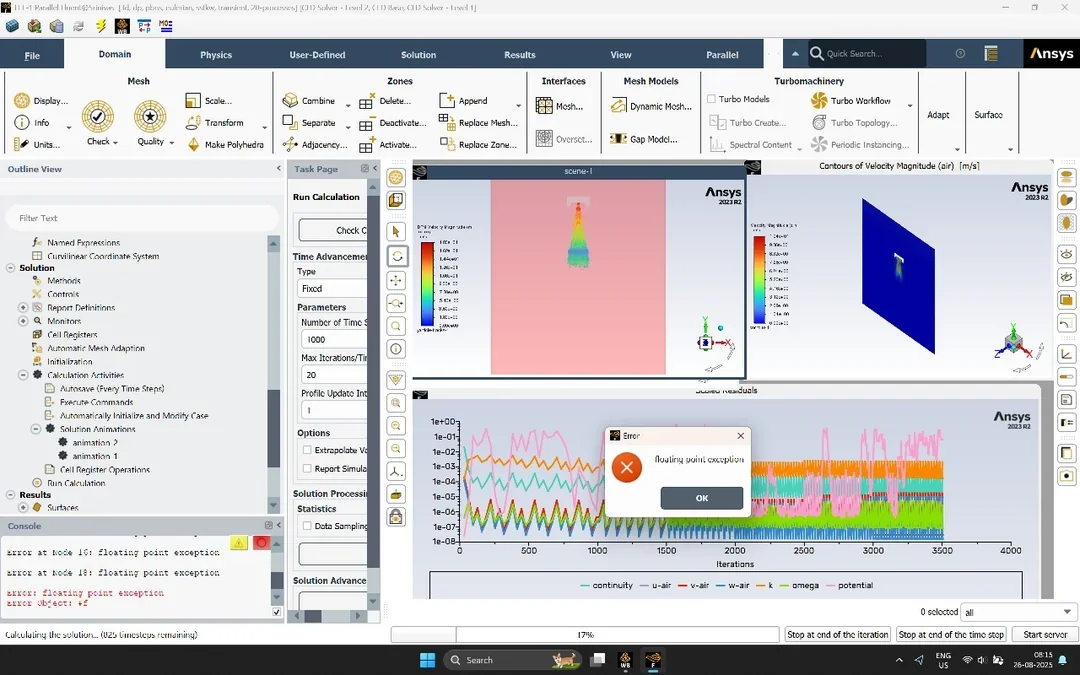

Boundary conditions (image 3);

(top face of enclouser)Downdraft vel (vel inlet): 0.3 m/s

Shaping hole inlet (vel inlet): 10 m/s

Assisting hole inlet (vel inlet): 8 m/s

Atomising air inlet (vel inlet): 3 m/s

Side walls (4 sides): pressure outlet

Substrate (bottom face of enclouser): reflect DPM (all other walls are set to escape for DPM) and voltage of -60,000 V

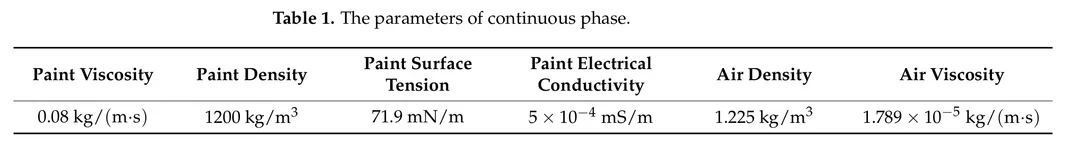

Material properties: image 4

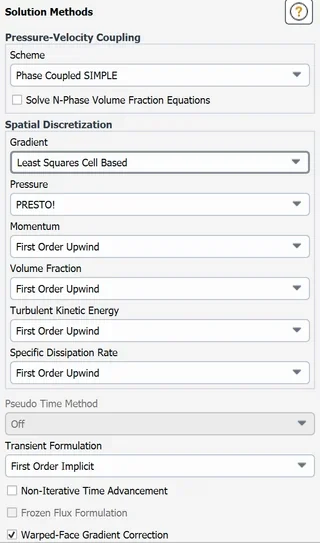

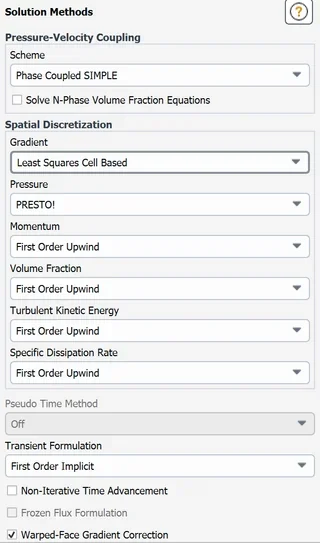

Methods: image 5

Number of Timesteps: 1000

Timestep size: 0.00005 sec

Iterations/ timestep: 20

The error is coming after 175 timesteps. Please help me with this analysis.

-

August 29, 2025 at 10:09 am

Rob

Forum ModeratorThe error is point at an instability in the solution. That could be linked to mesh resolution/quality or time step size. However, the other clue is the potential residual: what's causing it to bounce like that?

You're using DDPM so are interacting with both the DPM and Eulerian Multiphase model: do you actually need DDPM?

-

August 29, 2025 at 5:42 pm

makarand.srinivas24

SubscriberI think I would need DPM, because I'm simulating a spray. Also, mesh resolution is enough as the smallest feature is of 0.5mm, and I've given a face size of 0.2mm with 25 layers of inflation around the nozzle body. Also, I've refined the mesh in the area of flow of spray. Below I've attached an image.

-

September 1, 2025 at 10:44 am

Rob

Forum ModeratorI asked about DDPM. If you just use DPM what happens?

-

September 2, 2025 at 7:34 am

makarand.srinivas24

SubscriberCan you please, according to you, suggest to me a methodology for doing this analysis?

I’m currently trying to validate the analysis done in this paper: https://www.mdpi.com/2079-6412/13/10/1808

Please help me out

-

-

September 2, 2025 at 8:45 am

Rob

Forum ModeratorStaff aren't permitted to follow links. What has your project supervisor suggested?

-

September 2, 2025 at 11:33 am

makarand.srinivas24

Subscriberokay.

So the problem statement is to simulate the process of electrostatic spray coating of SIPIOL UV liquid on a cold plate (device used in a battery management system) and adjust parameters for getting optimum film thickness on the plate.

I am now trying to validate the CFD approach, using a research paper, and then I'll adjust some parameters, such as spray speed and the distance between the spray and the substrate.

so I need help in simulating above process.

-

-

September 2, 2025 at 12:30 pm

Rob

Forum ModeratorHave a look at DPM, and potentially Eulerian Wall Film.

-

September 2, 2025 at 1:29 pm

makarand.srinivas24

Subscriberok sir. I'll ask if I have any further doubts

-

-

- You must be logged in to reply to this topic.

-

3817

-

1388

-

1188

-

1100

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.