-

-

July 2, 2025 at 1:28 pm

youssef.badran

SubscriberHello,

I am trying to simulate the flow of a liquid inside the mesh shown below. I have applied a rotating boundary condition in Fluent without using a rotating mesh region.

However, I am encountering some issues with the liquid flow, which seem to be related to the mesh and/or the moving boundary.

Do you have any suggestions to help improve the results? Do you think I should use a refined mesh for the teeth and define this region as a rotating mesh zone with a sliding interface to the rest of the mesh?

-

July 3, 2025 at 8:23 am

Rob

Forum ModeratorSet the outer fluid zone to rotate using Mesh Motion (Cell Zone condition - it's the second option). I also hope that's not the mesh you were trying to use! If it was, please have a look at the various meshing courses on Learning.

-

July 3, 2025 at 12:41 pm

youssef.badran

SubscriberThank you very much for the information !

-

July 3, 2025 at 2:38 pm

youssef.badran

SubscriberI watched the following tutorial:

https://www.youtube.com/watch?v=FElQIvgDmLc&list=PLtt6-ZgUFmMKsQ-dh1SjyuiazlB9_aa-E&index=2

Do you think I should mesh the teeth separately using the 'body size' control type in Fluent Meshing, and apply a specific growth rate toward the center of the geometry?

-

-

July 3, 2025 at 3:38 pm

Rob

Forum ModeratorPossibly, try it. I'd probably just use size functions to start with. Have you also read up on sliding mesh?

-

July 3, 2025 at 4:16 pm

youssef.badran

SubscriberOK, thank you for your help.

Yes, I read about the sliding mesh approach, and as you suggested, I imposed mesh motion on the outer region—it seems to work.

I'm now working on improving the mesh quality, as you proposed. -

July 4, 2025 at 4:51 pm

youssef.badran

SubscriberHello,

I tried to mesh the outer region in SpaceClaim and obtained good element quality using hexahedral elements.

Please see the attached mesh. The geometry includes two solids: one for the outer region and one for the inner region (as shown in the second attached image).

I would like to mesh the inner solid using tetrahedral elements. However, when I do so, the mesh of the outer region is modified.

Could you please advise me on how to mesh the inner solid without affecting the outer one?

-

-

July 8, 2025 at 11:03 am

Rob

Forum ModeratorDon't use SpaceClaim meshing. If you use Ansys Meshing (in Workbench) or Fluent Meshing (check for a 2.5D option) you can use hex/tet in the former or extruded poly in the latter. You may want to move the split between the toothed and core volume a little too to avoid over constraining the mesh in the gap.

-

July 10, 2025 at 12:43 am

youssef.badran

SubscriberThank you very much for your help.

I increased the size of the outer region and used ANSYS Meshing in Workbench. Please see the attached screenshots. For the inner solid, I used tetrahedrons with an element size of 0.7 m. For the outer solid, I applied the Sweep method (which gave better element quality than tetrahedrons) with an element size of 0.1 m. I also applied a refinement on the outer face of the inner solid to reduce the error at the interface between the two solids.

Do you have any suggestions to improve the mesh quality?

I wanted the inner solid to have the same cell size at the interface as the outer solid and for the cell size in the inner solid to gradually increase toward its center. However, I was not able to achieve that.

-

-

July 10, 2025 at 7:56 am

Rob

Forum ModeratorI'd make the outer region even deeper so you can keep most of the liquid in the rotating zone. Keeping boundaries and changes in cell type away from areas of interest is generally a good idea as it means any odd results are likely correct and not a result of an (user) error in the settings.

In terms of the meshing approach you've chosen a good strategy. However, the cell size at the sliding interface contact needs to be roughly the same size. So, if it's 0.1m for hex your surface mesh wants to be that on the tet side: you can set a surface sizing. For good resolution of a free surface you need sufficient mesh in that region and you don't have that at present.

-

July 10, 2025 at 7:05 pm

youssef.badran

SubscriberThank you very much for your help.

I would increase the size of the outer region.

I tried using face sizing with an element size of 0.1 m to ensure the same cell size on both sides of the sliding interface. However, the mesh quality still seems to be low, as shown in the attached screenshot.

Do you have any suggestions for improvement?

Also, is there a way to gradually increase the cell size in the inner solid when moving toward the center?

-

-

July 11, 2025 at 9:05 am

Rob

Forum ModeratorRead up on growth rate for the tet region. Look at minimum size for proximity function, aim for 5-10 cells across a tooth. You need to resolve the flow, and you aren't with that mesh.

-

July 14, 2025 at 3:15 pm

youssef.badran

SubscriberThank you for the information.

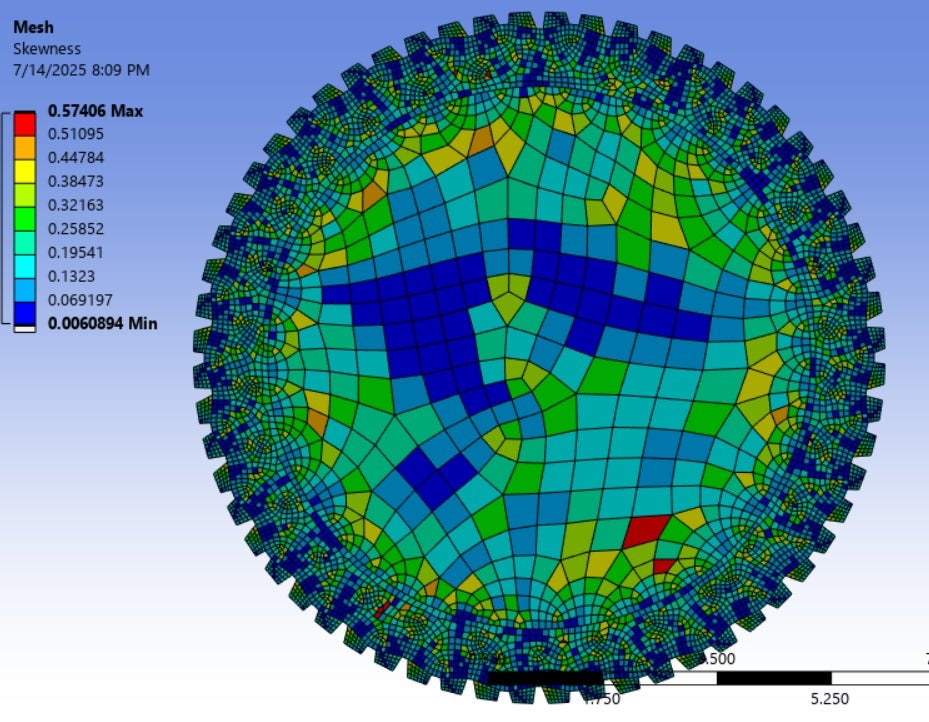

I applied sizing to the edges of each tooth. Please see the attached mesh.

As you can see, the mesh quality in the outer region is good.

For the inner region, I used face sizing with an element size of 0.1 m, which matches the element size in the outer region.

However, the element quality in the inner region is not satisfactory. Do you have any suggestions for improvement?

-

-

July 14, 2025 at 3:26 pm

Rob

Forum ModeratorThat looks better. What sizing did you pick for the inner volume? Use skew for the metric, "element quality" is a Mechanical check.

-

July 14, 2025 at 3:46 pm

-

-

July 14, 2025 at 3:49 pm

Rob

Forum ModeratorHard or soft setting? That's bad; 0.9 is borderline, 0.95 needs fixing and anything above that is really bad.

-

July 14, 2025 at 4:07 pm

youssef.badran

SubscriberSoft.

Ok, thank you for the information. -

July 14, 2025 at 4:12 pm

youssef.badran

SubscriberIn the literature, the tetrahedral mesh is converted into a polyhedral mesh to minimize overall cell skewness. Is there a way to apply this conversion only to the inner solid?

-

-

July 14, 2025 at 4:20 pm

Rob

Forum ModeratorThe poly conversion only works on tets (I think) but isn't widely used now we have a better direct poly mesher. Don't rely on it to fix your problems either - it'll not help with the jump in cell size. Soft shouldn't be that extreme - it's intended to take existing surface mesh first.

-

July 15, 2025 at 11:52 am

-

-

July 15, 2025 at 12:20 pm

Rob

Forum ModeratorThat looks a lot better.

-

- You must be logged in to reply to this topic.

-

3492

-

1057

-

1051

-

965

-

942

© 2025 Copyright ANSYS, Inc. All rights reserved.