TAGGED: -2d-materials-and-metals

-

-

May 10, 2025 at 2:03 am

891348308

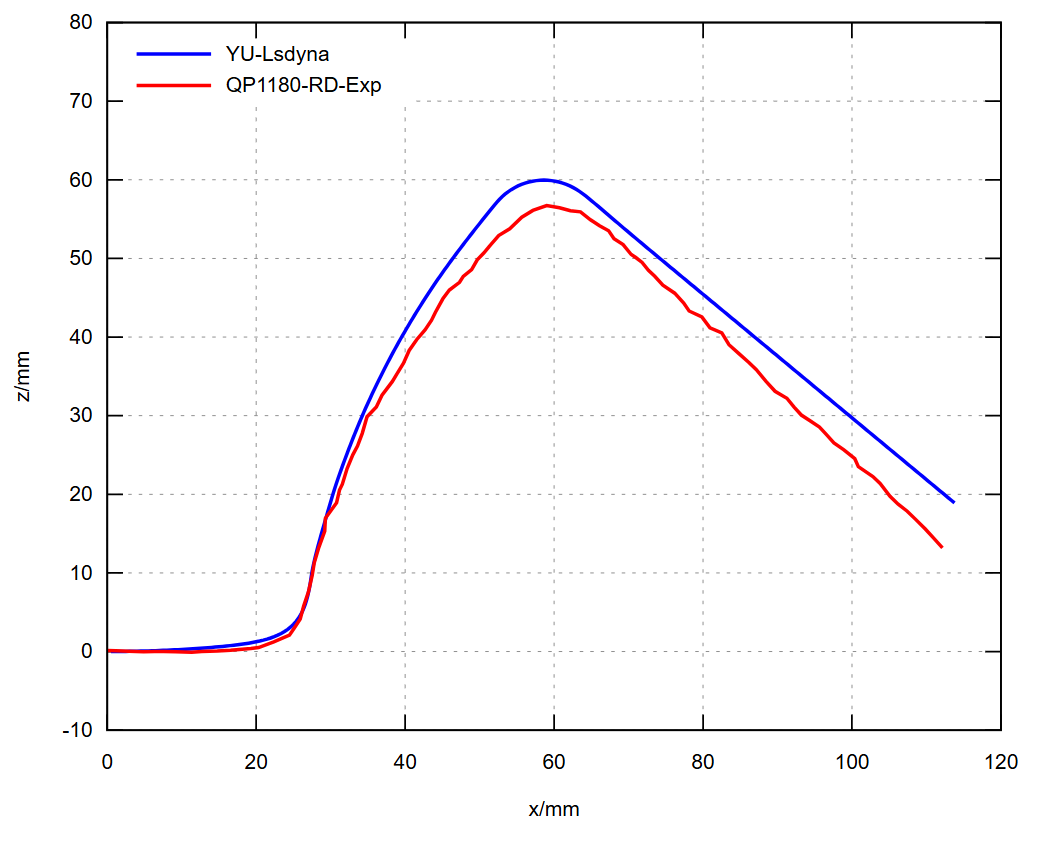

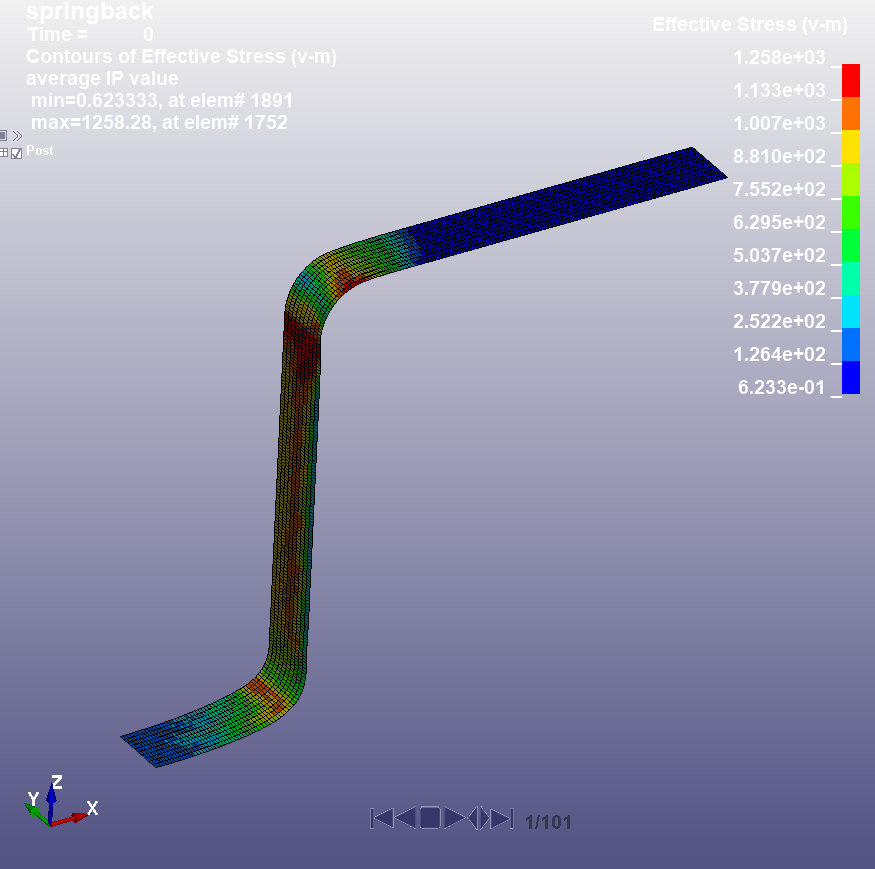

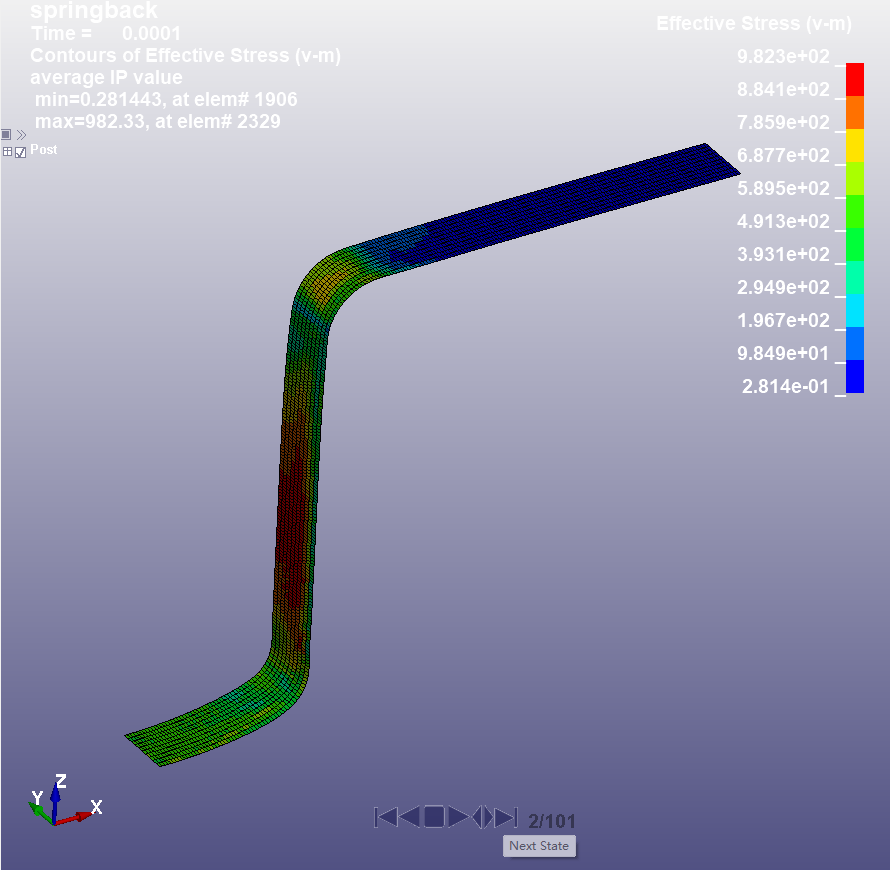

SubscriberI am working on the analysis about U-bending and spirngback of sheet metal. I used explicit analysis for forming stage and implicit analysis for springback stage(dynain method). But I found the springback smaller than experiment. When I lookeg into the springback process, The running window found negeative eigenvalue, and the first springback step revealed a rather unreasonable stress distribution. I referred to many tutorials and essays but didn't solve the problem. By the way, the material I am using now is MAT125.I would be very appreciate if anyone can help.

-

May 12, 2025 at 12:45 pm

Ram Gopisetti

Ansys EmployeeHi,

For implicit spring back, are you using proper implicit controls as given here https://lsdyna.ansys.com/wp-content/uploads/2024/09/Ansys_LS-DYNA_implicit_guideline_2024R2.pdf

Also, I see the curve given by dyna is close enough to the experiment ( expecting a one-to-one match with experiments might not be realistic in some cases), and perhaps tuning some tolerance parameter from the above guide should improve the condition.

Cheers, Ram

-

May 13, 2025 at 12:12 pm

891348308

SubscriberThank you a lot for admitting my work and your answer is really helpful to me. By referring to the manual and switching to full Newton approach, the negative eigenvalue warning no longer pops out.

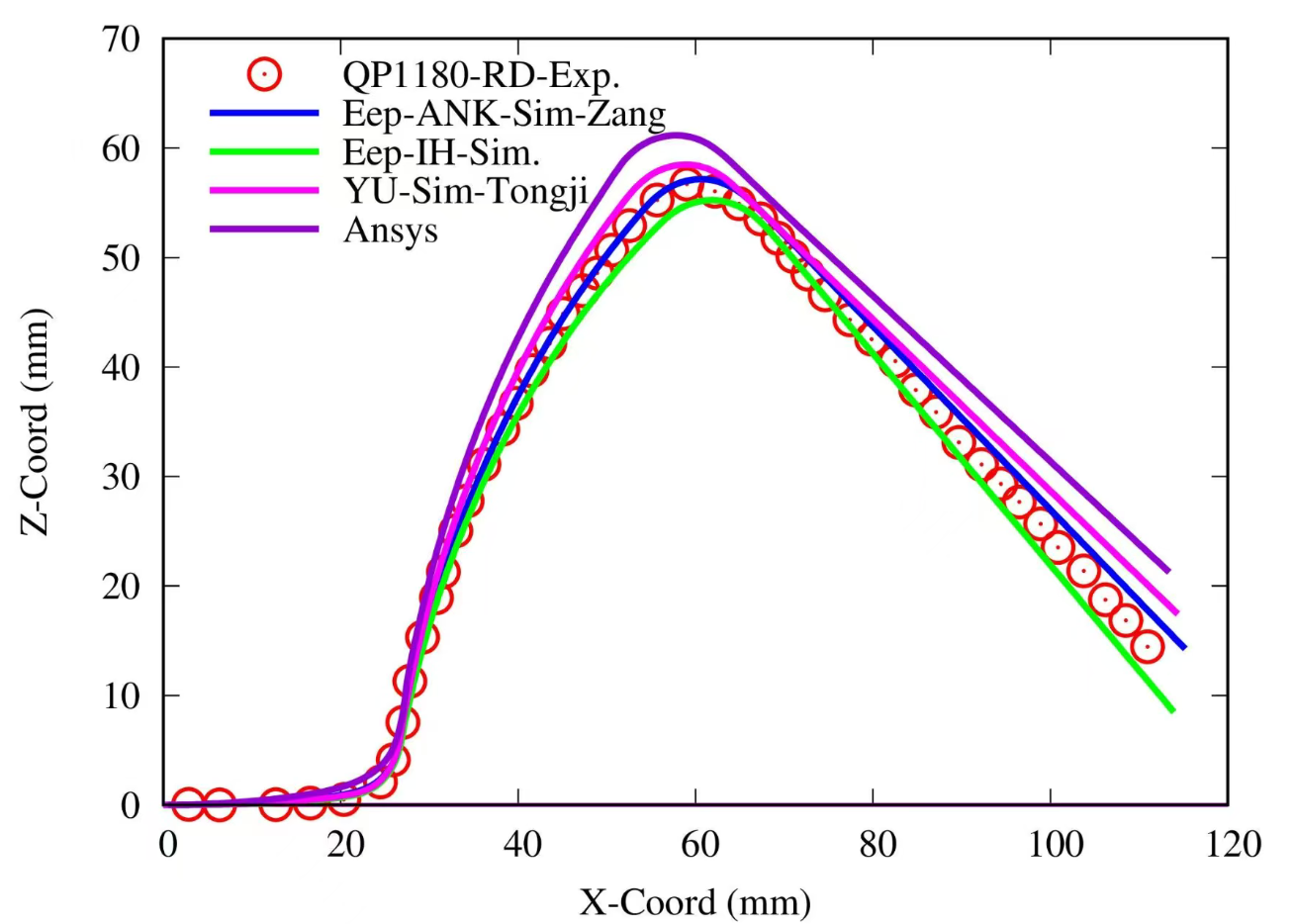

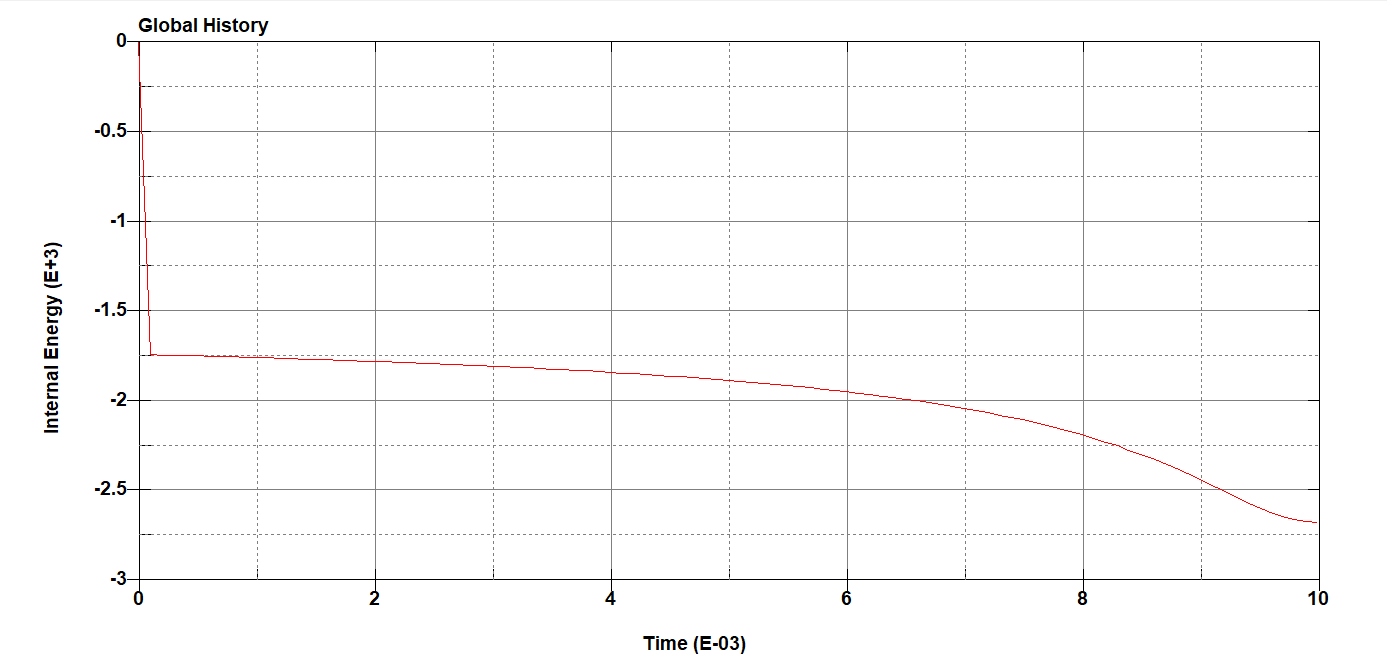

However, the spring back shape(Ansys plot in fig.1) didn't seem to improve, still less than expected(YU-Sim-Tongji plot in fig.1) even though I tried to modify the tolerance parameters. I looked into the springback process and found the first step have a greater deformation than the following steps and the internal energy dropped significantly(fig.2) at first. How did this happen and was this the main reason for the underestimated spring back?

Thanks again for your professional help!

-

-

- You must be logged in to reply to this topic.

-

3044

-

971

-

884

-

858

-

792

© 2025 Copyright ANSYS, Inc. All rights reserved.