-

-

April 21, 2020 at 4:46 am

nshepard6

SubscriberHello,

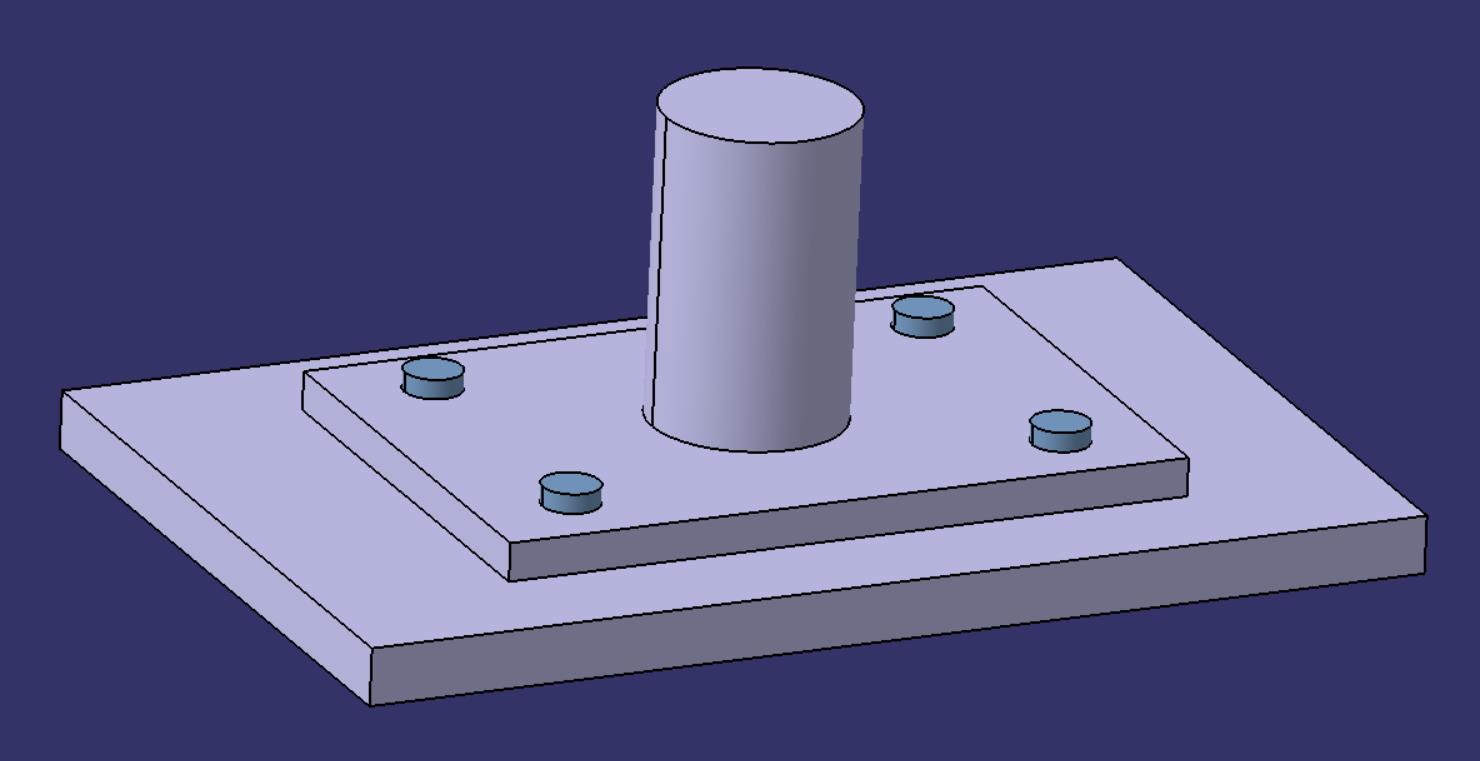

I'm trying to create a simplified 2D representation of a plate-bolt assembly where two plates are bolted together with a bolt pretension applied and a cylinder applies a force to the top plate. I've attached a picture of the 3D model. When I went to model the assembly in a simplified 2D version, I created mid-plane surfaces for the two plates and a beam element for the cylinder. I've included a picture for what the 2D assembly looks like and its loads/constraints.

The defined contacts are a manual bonded contact between the line/beam element's bottom vertex and the top plate's surface as well as a manual friction contact between the top and bottom surfaces. For the friction contact, I've tried to change it to "Adjust To Touch" as well as "Add Offset, No Ramping" and it still errors out. The top and bottom surfaces have bolt holes connected by beam contacts with a corresponding pretension applied to match the 3D model. The bottom plate has a fixed support applied to the face. I have tried to model the beam contacts as rigid or as the beam behavior and the solution errors out before it gets very far. The error message is: "An internal solution magnitude limit was exceeded. Please check your Environment for inappropriate load values or insufficient supports. Please see the Troubleshooting section of the Help System for more information."

I have tried looking at this multiple ways but I can't find where the insufficient supports would be. Can you help me troubleshoot this?

Thanks in advance!

-

April 21, 2020 at 4:43 pm

Wenlong

Ansys EmployeeHi,

For a troubleshooting purpose, I would suggest starting with a simpler model. For example, you can first suppress other parts but only leave the beam and the yellow plate. If it works, you can try adding back the blue plate. This may help you narrow down where the problem could be.

Regards,

Wenlong

-

April 21, 2020 at 5:37 pm

nshepard6

SubscriberWenlong,

Thank you for responding. I tried suppressing everything except the yellow plate and the beam with the load. Since I removed the bottom plate with the fixed support, I moved the fixed support to the yellow plate. When I tried that, I got the below errors which isolate the problem to the beam element but I'm still confused.

"An internal solution magnitude limit was exceeded. Please check your Environment for inappropriate load values or insufficient supports. Please see the Troubleshooting section of the Help System for more information.

An internal solution magnitude limit was exceeded. (Node Number 34044, Body BarBeam (Circle), DOF UY) Please check your Environment for inappropriate load values or insufficient supports. You may select the offending object and/or geometry via RMB on this warning in the Messages window. Please see the Troubleshooting section of the Help System for more information."

I'm not sure what supports the beam would need. It is connected to the yellow plate by a bonded contact but there is a gap between the 2D objects (when viewed in 3D as with the mesh they are touching if that helps).

Thanks again,

Nick

-

April 21, 2020 at 6:25 pm

Wenlong

Ansys EmployeeHi Nick,

There are several things you can check:

1. Make sure the beam and the plate are bonded. I guess this is already handled since you are using "adjust to touch". For the yellow plate, are you using shell? I ask because if it is solid, there may be some issues constraining the rotational DOF of the beam node. A beam node has 6 DOFs and a solid node only as 3 DOFs, and that may be the reason it shows insufficient supports.

2. Can you please share an image of the load you applied to the beam? Did you apply it as a step load? In that case, it may also cause an issue as the load is applied in a sudden manner and the solver is not able to find the force balance. If that is the case, you may try slowly ramp up the load within a certain period of time.

3. In the analysis settings, have you turned on automatic time stepping? It may help to define many substeps (For example, you may try "initial substeps=10, min=5, max=100) and in that case, the governing equation is solved for a small increment at once.

FYI, the beam you have is still a 3D object, although it is just a line. This is because it can move in all x, y, and z directions.

Regards,

Wenlong

-

April 21, 2020 at 6:41 pm

nshepard6

SubscriberWenlong,

I think the issue must be with the beam element not properly bonded to the plate. Below shows the bonded contact information. I think the plate is a shell element. In SpaceClaim, I took the 3D solid plate and performed the midplane operation on it to get the surface element. The second image is the loading step where it was just a step load. I even decreased the load to 200 lbf in case the loading was too high. I will apply your recommendations for 2 and 3 but it seems like the bonded contact is the source of the issue.

Thank you so much!

Nick

-

April 21, 2020 at 6:54 pm

Wenlong

Ansys EmployeeHi Nick,

To check the contact, you can right-click on "Connections"-->insert-->"Contact tool", then right-click on "contact tool", and insert an "initial information". Click on the contact tool, then click on that "Add" button as shown below.

Then right-click on "initial information" -->"Generate initial contact results", then you will see the status of your contact as shown below.

As you can see my contact status shows "closed", which means they are in contact.

Regards,

Wenlong

-

April 21, 2020 at 7:04 pm

-

April 21, 2020 at 8:06 pm

-

April 21, 2020 at 8:14 pm

nshepard6

SubscriberThe top face was selected and I reran the contact tool again just to make sure. When I checked the distance between the beam and surface in SpaceClaim, it came back as coincident. Any suggestions?

I really appreciate your help on this.

Thanks,

Nick

-

April 21, 2020 at 8:31 pm

Wenlong

Ansys EmployeeHi Nick,

Can you please share a screenshot of your mesh? Thanks!

Regards,

Wenlong

-

April 21, 2020 at 8:35 pm

-

April 21, 2020 at 8:43 pm

Wenlong

Ansys EmployeeOh, so you are not using beam elements. These are solid elements for the column but that's alright. Just making sure, in your current simulation, you only have the following things defined, right?

- You are only modeling the upper column and the yellow plate

- There is a fixed b.c. applied to the plate

- There is a bonded contact applied to the lower surface of the column and the top surface of the plate.

- You applied a load to the top surface of the column.

There is another thing you can try: apply a larger pinball radius. The pinball radius can be visualized and make sure it covers both the column and the yellow plate.

Regards,

Wenlong

-

April 22, 2020 at 3:55 am

nshepard6

SubscriberI realized after your response that I included an old mesh picture that didn't have the beam element. Below is the mesh with the beam element. After going through your last response, changing the pinball radius is what made the beam-top plate assembly work. I added in the bottom plate and beam connections between the top and bottom plate with the assembly still working. I now have the assembly churning out results. Below is a picture of the equivalent stress results for the 2D vs. 3D models. The 2D stress on the assembly is half that of the 3D assembly. Does that make sense or is there something else wrong with the 2D model?

Thank you for all your continued help on this!

Nick

-

April 22, 2020 at 8:21 pm

Wenlong

Ansys EmployeeHi Nick,

In this case, I don't recommend using beam elements. Beam elements are suitable when the length is significantly larger than the cross-section area. In your case, however, the cylinder is too thick. Moreover, you are interested in the stress distribution at the interface of the cylinder and the plate, but using beam elements only considers the end node of the beam for contact (It is visualized in your second image, where only the stress around the beam end node is high).

Regards,

Wenlong

If this answers your question, please check the "Is Solution" button to help others, otherwise, feel free to follow up.

-

- The topic ‘Insufficient Supports on a 2D Simplified Model’ is closed to new replies.

-

3129

-

1002

-

912

-

858

-

792

© 2025 Copyright ANSYS, Inc. All rights reserved.