-

-

March 21, 2020 at 6:03 pm

momidor

Subscriber

Dears,

I've bumped into contact/mesh/ect problems. It's my first two steps simulation: thermal and structural, and since this morning I have not cope with flood of errors.

All hereunder errors refers to bonded contacts only. All this happen on the first step where I have three in total. Actually in first substep even. I have 10 substeps.

Thanks in advance for tips

-

March 21, 2020 at 7:34 pm

peteroznewman

SubscriberDrop a Modal analysis on the Transient Structural Model cell. Drag down the support from the Transient Structural branch to the Modal branch. Solve the Modal and see what the frequencies are for the first six modes. Are they all practically zero?

-

March 21, 2020 at 8:22 pm

-

March 22, 2020 at 2:15 am

peteroznewman

SubscriberWhy do you need contact elements? Why don't you just have elements connected to nodes?

-

March 22, 2020 at 6:40 am

momidor

Subscriber -

March 22, 2020 at 11:16 am

peteroznewman

SubscriberIf you have two bodies that have coincident faces, each body is meshed with its own set of nodes and elements. Then you have contact elements created between the two faces that connect the nodes on the face of one body with the nodes on the face of the other body. The nodes don't have to be coincident.

Instead of using Contact elements to bond the faces together, use Shared Topology. That means one set of nodes are created on the coincident face and elements from each body use those shared nodes to connect the two bodies together. Then you don't need Contact elements.

Share is a button on the Workbench tab of SpaceClaim. Then in Workbench, the mesher will automatically create a shared set of nodes on coincident faces.

-

March 22, 2020 at 11:48 am

-

March 22, 2020 at 2:52 pm

peteroznewman

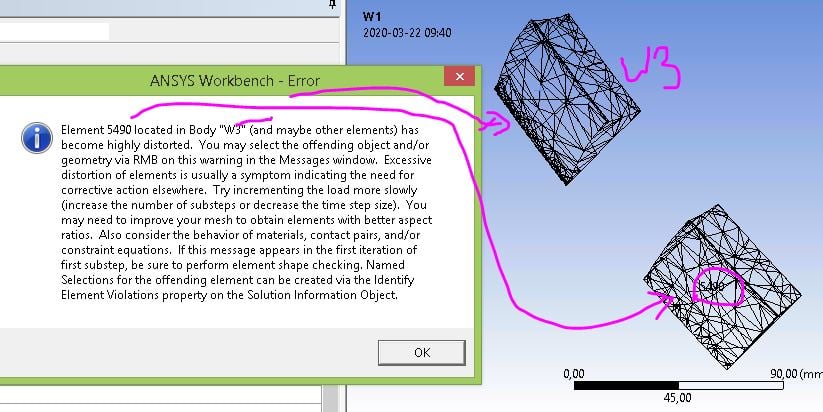

SubscriberNow you need to follow the advice given in the Error message.

The problem is in Step 2.

Under Analysis Settings, set the Current Step number to 2.

Change the Auto Time Stepping to On.

Change the Initial Substeps to 100

Change the Minimum Substeps to 100

Change the Maximum Substeps to 1000

Change Large Deflection to On.

Under the Solution Information Folder, set the Newton Raphson plots to 3 and set the Element Violations to 3.

The last item automatically creates a Named Selection at the end with the elements that failed.

When you see those, remesh with smaller and better shaped elements.

-

March 24, 2020 at 5:12 am

momidor

SubscriberHi,

I did it but is working extremely slowly. First second from 40 in total took a half day. I applied a Steady-State Thermal - and - Static Structural.

Should I used Thermal Transient and transient Structurla to accelerate it ?

Thanks in advanced.

Jurek

-

- The topic ‘Transient Thermal / Structural’ is closed to new replies.

-

3767

-

1333

-

1168

-

1090

-

1014

© 2025 Copyright ANSYS, Inc. All rights reserved.