-

-

December 21, 2024 at 8:15 am

Alassedi

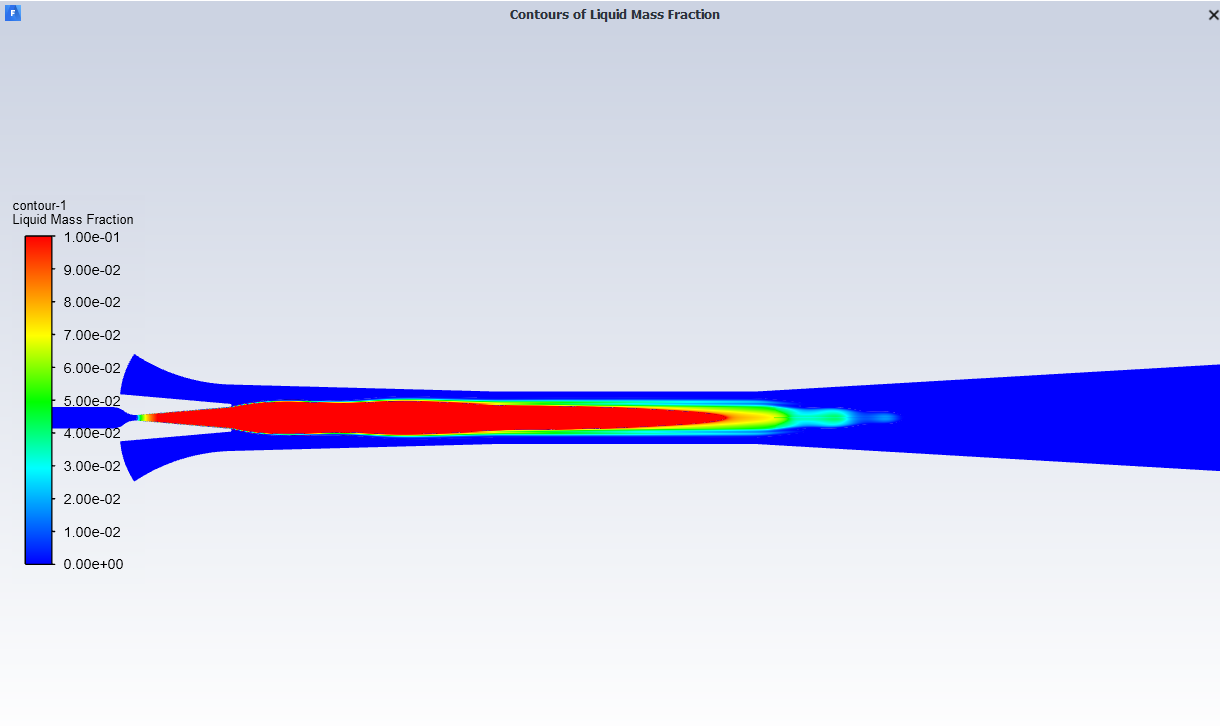

SubscriberResidual Convergence Challenges for Liquid Fraction in Wet Steam Ejector Flows

I am currently conducting a computational fluid dynamics (CFD) simulation of wet steam flow through a Sriveerakul nozzle. The following boundary conditions have been specified:

· Multiphase Model Type: the built-in wet steam model

· Turbulence Model: k – ω SST

· Primary Inlet: Pressure inlet at 198,665 Pa, temperature at 393.15 K, and a liquid mass fraction of 0.1%

· Secondary Inlet: Pressure inlet at 1,228.18 Pa, temperature at 283.15 K, and a liquid mass fraction of 0.1%

· Outlet: Pressure outlet at 3,000 Pa, temperature at 283.15 K, and a liquid mass fraction of 0.0%

· Spatial Discretization: second-order upwind schemes for momentum and energy

· Pressure-Velocity Coupling Method: Coupled

· Initialization: hybrid initialization

· Mesh Type: structured

· Mesh Quality: Max skewness 0.36, Min orthogonality 0.84

· Refinement near critical regions (nozzle throat, shock regions, wall boundaries)

Despite using these conditions, the residuals for the liquid mass fraction have not converged. I would greatly appreciate any insights into potential reasons for this lack of convergence and suggestions on how to achieve a stable solution for the liquid mass fraction in wet steam simulations.

-

December 23, 2024 at 11:19 am

Rob

Forum ModeratorPressure boundaries tend to me more difficult to converge as the mass flow becomes part of the solution which can create feedback issues. Is the model transient? Note, ejectors tend to be fairly difficult in that you have high speed, phase change and dead space in the domain. You may also need a lot more mesh in the core region to capture shocks etc. The two equation models aren't always well suited for this type of flow, you may need to review RSM too.

-

December 23, 2024 at 2:14 pm

Alassedi

SubscriberThank you for your response. The model is steady-state. The issue appears to stem from a constraint on the liquid mass fraction, which is currently capped at 0.1. Could you please advise on how to redefine this limit to fall between 0.0 and 1.0 so that the simulation can accommodate the full range of physically expected values? Please note that the liquid mass fraction limit does not appear in Solution > Control > Limits...

-

December 23, 2024 at 2:21 pm

Rob

Forum ModeratorWhy would the liquid fraction be capped at 0.1? How have you acheived that?

-

December 23, 2024 at 2:35 pm

-

December 23, 2024 at 2:38 pm

Rob

Forum ModeratorYou've also got streaking in the contour so I'd run on. Check the contour scale settings too.

-

- You must be logged in to reply to this topic.

-

4607

-

1515

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.