TAGGED: ansys-mechanical

-

-

December 18, 2024 at 2:09 pm

shailesh.fulse

SubscriberHello,

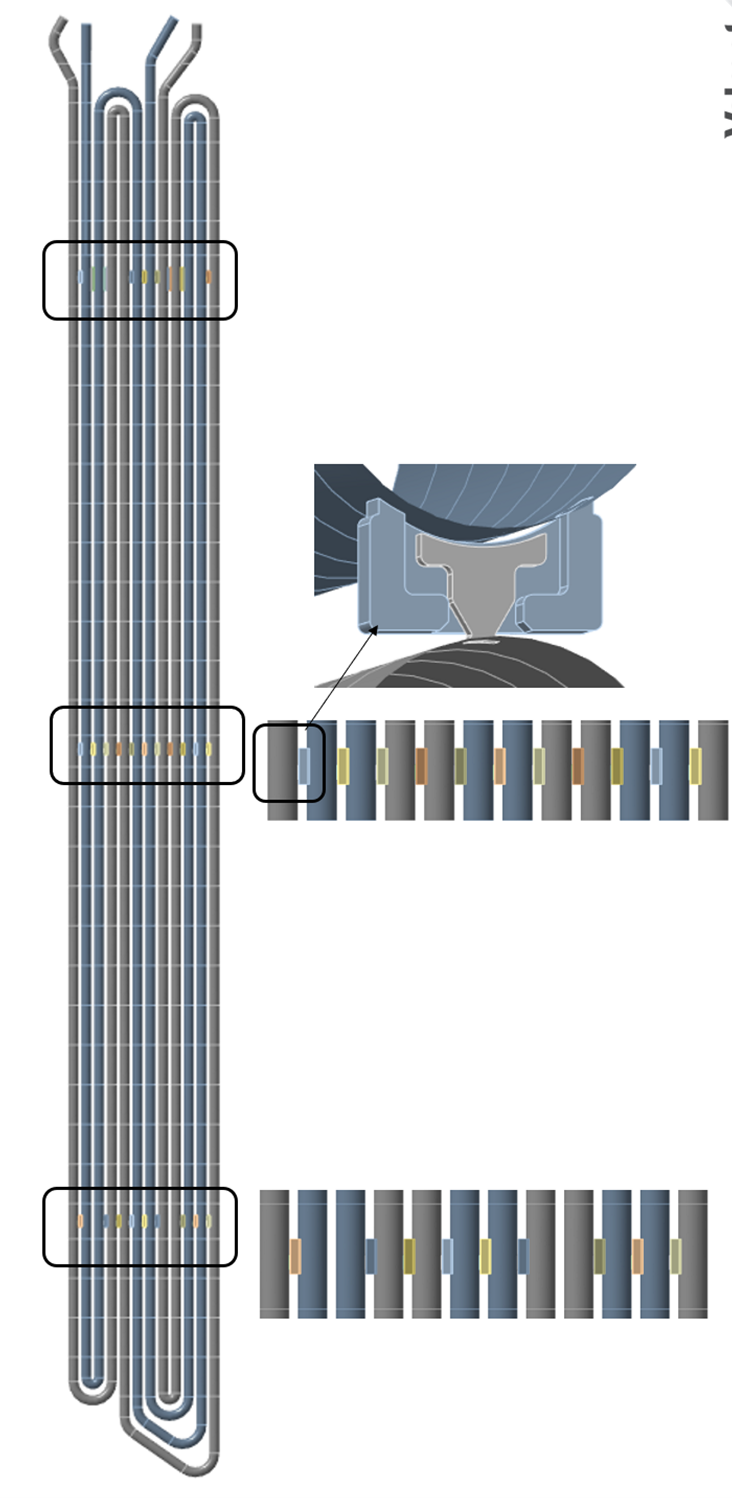

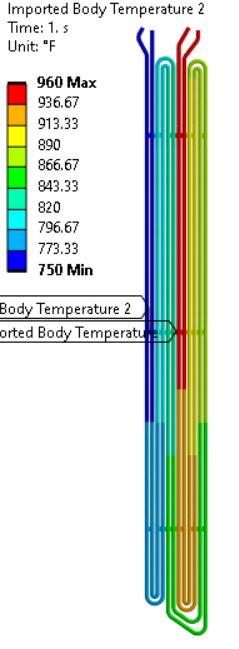

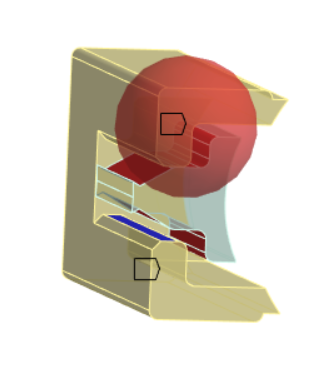

I am doing an analysis of tubes under high tempratures (varying across length) as shown below. Tubes have some sliding connection to each other (sliding inner and sliding outer) and . They can expand vetically. Lateraly sliding parts have some gap, which allows some movement. Tubes are fixed at top. SMall tie

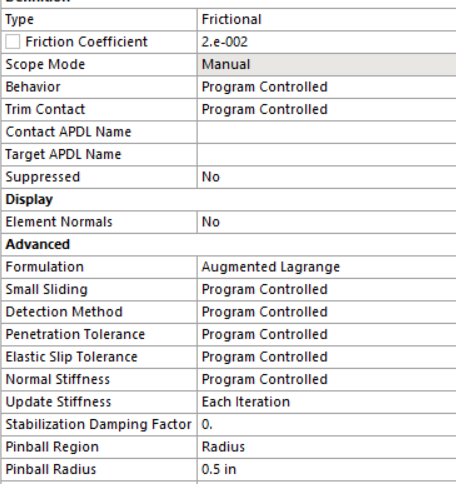

Inner sliding is bonded with one tube and outer sliding with adjuscent tube. I have created frictional contact between two sliding parts with very small friction (0.02), I have kept pinball radius also large so intial contact can be created. There is also few more friction contact which are close and can come in contact.

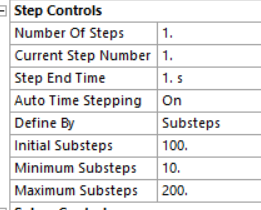

Analysis settings are like following

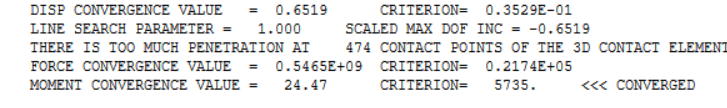

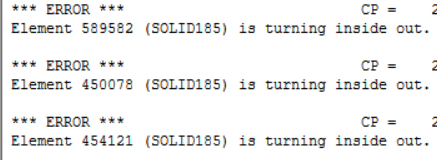

But I am getting follwoing errors at first step.

I have tried to change normal stiffness fraction but still not able to solve. I fixed few connection which is not correct situation but it was giving lot of penetration at few location and some frictional contact were not working.

Mesh is fine at the contacts, but still I am getting this error.

How to fix this issue

-

December 19, 2024 at 11:37 am

Ashish Khemka

Forum ModeratorHello,

Do you have mid-side nodes for the mesh? Please check and see if you are using a programmed controlled mesh.

Regards,

Ashish Khemka

-

December 19, 2024 at 1:48 pm

shailesh.fulse

SubscriberHello,

There are no midside nodes. I have kepy element order linear for this.

-

December 19, 2024 at 1:52 pm

Ashish Khemka

Forum ModeratorHi Shailesh,

Try using a mesh with mid-side nodes (program-controlled/ non-linear).

Regards,

Ashish Khemka

-

December 19, 2024 at 4:55 pm

shailesh.fulse

SubscriberHi Ashish,

I tried with Programme control mesh, the solution is not converging. It is bisecting in first iteration and then run turminates.

Defromation of unconverged solution is also very high.

Solution not converged at time 5.E-03 (load step 1 substep 1).

Run terminated. -

December 20, 2024 at 12:35 am

Ashish Khemka

Forum ModeratorShailesh, for the frictional contacts: Turn off small sliding, and reduce pinball radius (current one looks too large). Check the initial contact status: Does the model has penetration?

If yes, then you will need to resolve it first (setting the first step to resolve the penetration), then importing the temperatures and then allowing for sliding.

If not, then try to use a coarse mesh and try to debug why the model is not converging. You may try using Newton Raphson Residuals as well to look for locations of force imbalance.

9.6.8.3. Addressing Non-Convergence

Regards,

Ashish Khemka

-

- You must be logged in to reply to this topic.

-

5279

-

1885

-

1403

-

1262

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.