TAGGED: #fluent-#cfd-#ansys, mesh, wind-turbine, wind-turbine-cfd

-

-

December 5, 2024 at 10:48 am

safiya.cheick_ismail

SubscriberHi everyone,

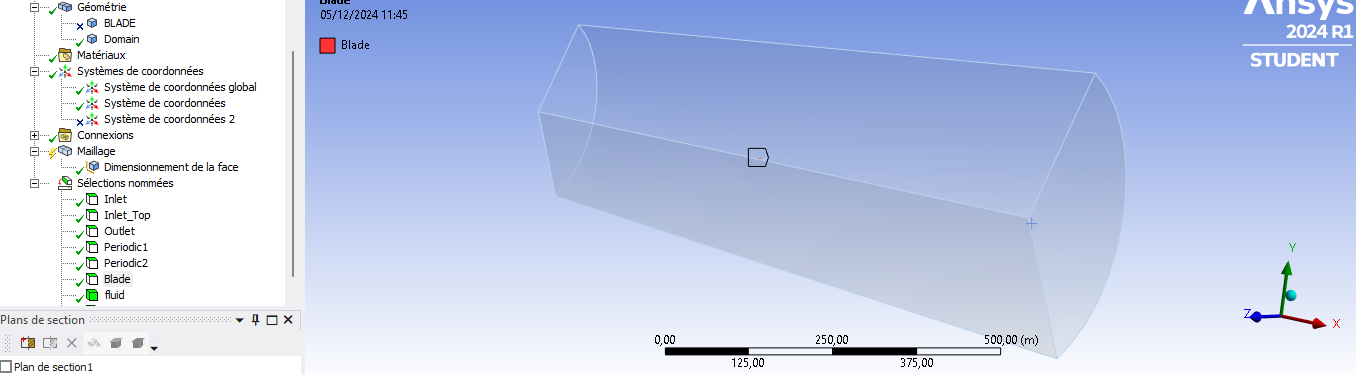

I'm trying to simulate flow around a wind turbine blade using cyclic symmetry in ANSYS. Here’s what I’ve done so far:

- Imported the blade geometry as a STEP file into DesignModeler.

- Created a 1/3rd cylindrical fluid domain and subtracted the blade from it to define the flow region.

The problem arises during meshing. While I can successfully mesh:

- The fluid domain,

- The edges of the blade,

I’m unable to mesh the surface of the blade itself. I’ve tried the following steps without success:

- Applying Named Selections to the blade's face.

- Directly selecting the face of the blade geometry for meshing.

- Tried multiple mesh sizes.

No matter what I do, the surface meshing fails, and I can’t identify the root cause of the issue.

Has anyone encountered a similar problem or have any advice on how to resolve this?

Thank you!

-

December 5, 2024 at 11:43 am

Rob

Forum ModeratorCheck the minimum cell size you're using. With a 10m blade in a 500m domain you may struggle with cell count.

-

December 5, 2024 at 12:06 pm

safiya.cheick_ismail

SubscriberI use a minimum local mesh size of 0.5m for a 30m blade and a global mesh size of 50m for a 900m domain.

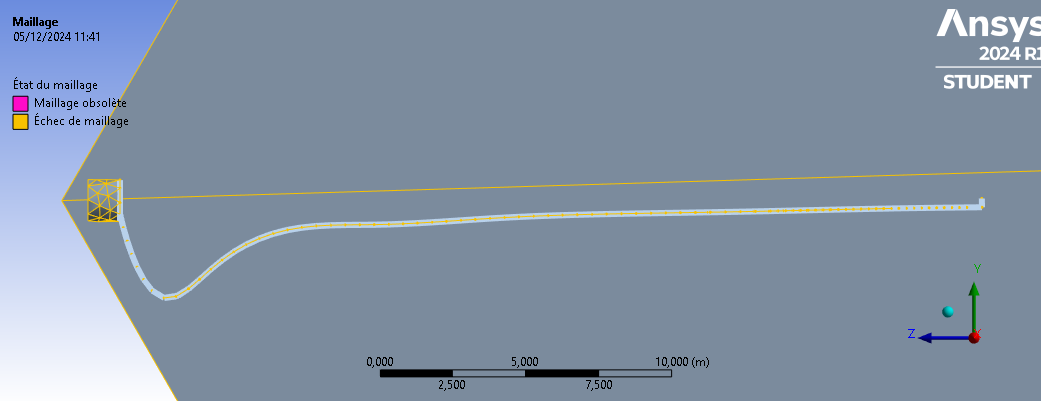

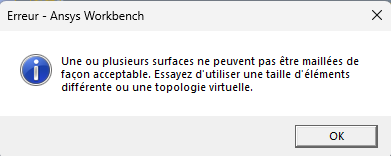

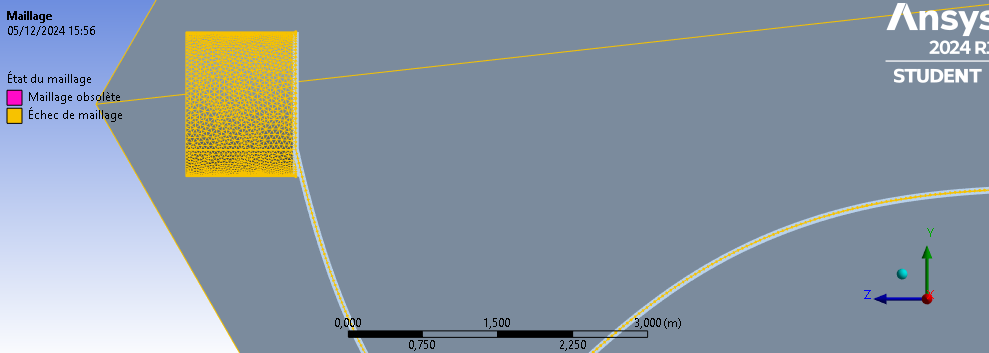

Here are the error messages:

"One or more surfaces cannot be meshed acceptably. Try using a different element size or virtual topology."

Some boundaries of protected topologies have been simplified.

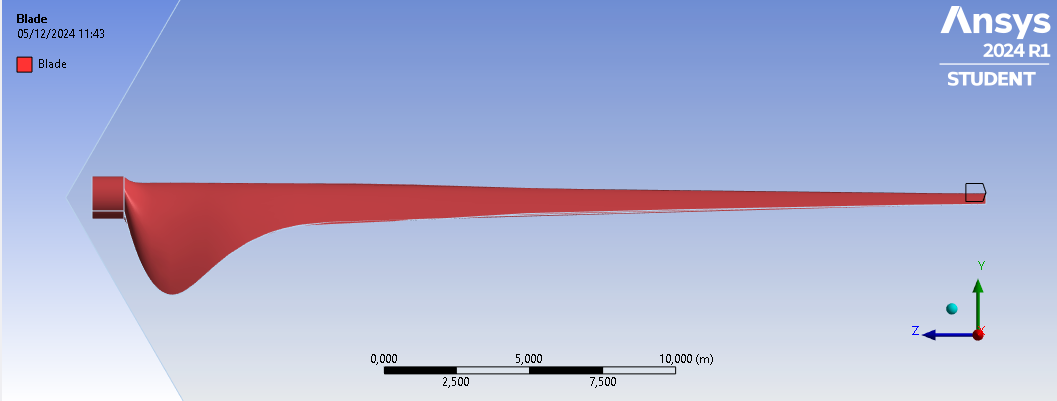

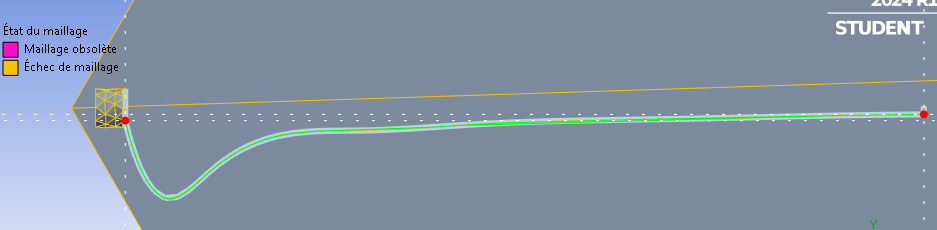

And here is the problematic geometry:

I tried bigger and smaller local mesh sizes but neither worked.

-

-

December 5, 2024 at 2:07 pm

Rob

Forum ModeratorAnd how thick/wide is the blade?

-

December 5, 2024 at 2:13 pm

safiya.cheick_ismail

Subscriberaround 0.1-0.3m

-

-

December 5, 2024 at 2:15 pm

Rob

Forum ModeratorHow well will a 0.5m cell resolve that?

-

December 5, 2024 at 2:20 pm

-

-

December 5, 2024 at 2:32 pm

Rob

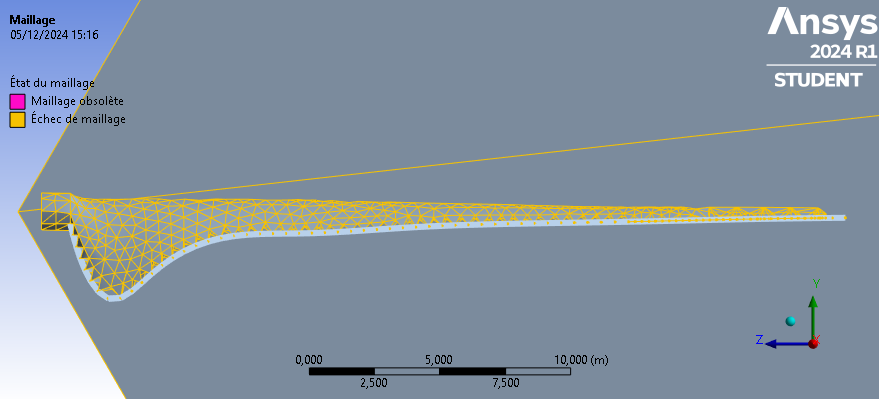

Forum ModeratorTry a minimum size of around 0.05m and see what happens.

-

December 5, 2024 at 2:37 pm

-

-

December 5, 2024 at 2:49 pm

Rob

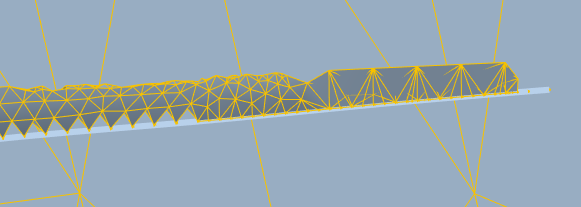

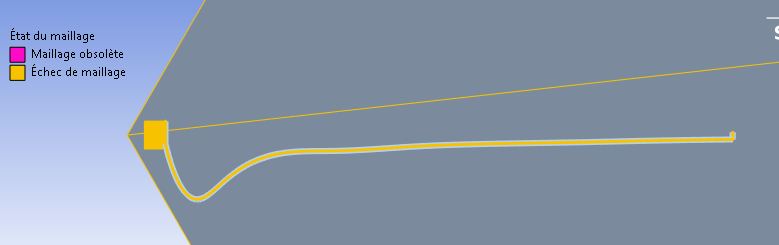

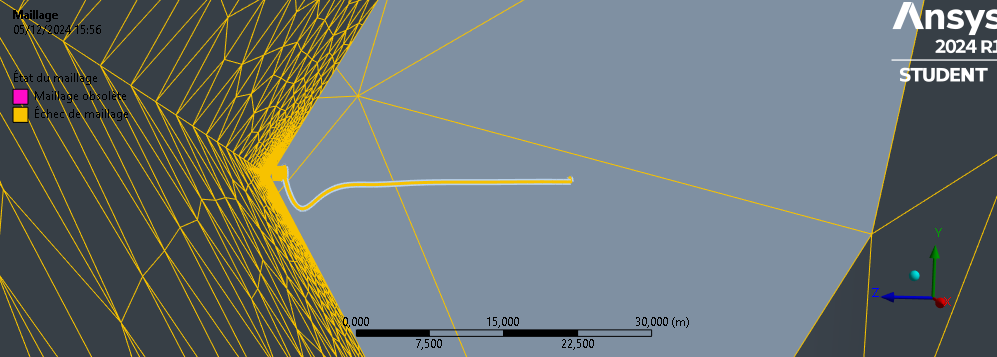

Forum ModeratorIt's yellow? Maybe try zooming in.

-

December 5, 2024 at 2:57 pm

-

-

December 5, 2024 at 2:59 pm

Rob

Forum ModeratorLooks better. How does the rest of the domain look? Note, you may struggle to mesh this in under 1M cells if you're using Student version.

-

December 5, 2024 at 3:03 pm

-

-

December 5, 2024 at 3:34 pm

Rob

Forum ModeratorAnd the geometry checks OK at that stage?

-

December 6, 2024 at 7:34 am

safiya.cheick_ismail

SubscriberYes

-

December 6, 2024 at 2:36 pm

Rob

Forum ModeratorAnd the blade is definitely void? A relatively fine surface mesh should work well, but if it's too coarse it'll not handle the curvature well. You may need an even finer mesh to capture the blade profile.

1375939052's approach has merit, but may be less accurate.

-

-

-

December 6, 2024 at 6:46 am

1375939052

Subscriber是否可以将刀片用作没有厚度的壁?如果您真的没有解决方法,可以试一试。

-

December 6, 2024 at 2:34 pm

Rob

Forum ModeratorIs it possible to use a blade as a wall without thickness? If you really don't have a solution, give it a try.

You can, but that may or may not give the correct drag due to the profile. It's commonly used in mixing tanks where the blades are flat plates (Rushton Turbine).

-

-

- You must be logged in to reply to this topic.

-

4678

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.