-

-

November 25, 2024 at 10:52 pm

Saeed

SubscriberHello,

I conducted a series of Fluent-Rocky simulations for a mixing tank to investigate the effects of fluid viscosity on particle behavior. In these simulations, the particles were less dense than the fluid so they tend to go upwards and float on top of the tank, and viscosity was varied between 1 cP and 100 cP, while all other parameters remained constant. Contrary to expectations, increasing the fluid viscosity resulted in fewer particles remaining at the top of the tank and improved particle distribution. This behavior is unexpected, as higher viscosity is typically associated with greater resistance to particle drawdown. Can you please help me with it?

Thanks

-

November 26, 2024 at 11:57 am

Rob

Forum ModeratorWhat is the flow field showing you? Higher viscosity will tend to reduce the likelihood of particles not following the flow.

-

November 26, 2024 at 4:00 pm

Saeed

SubscriberI compared the abs velocity of the particles and by increasing the viscosity it decreases but particles spread out and distribute in tank more and better by increasing the viscosity which is not correct.

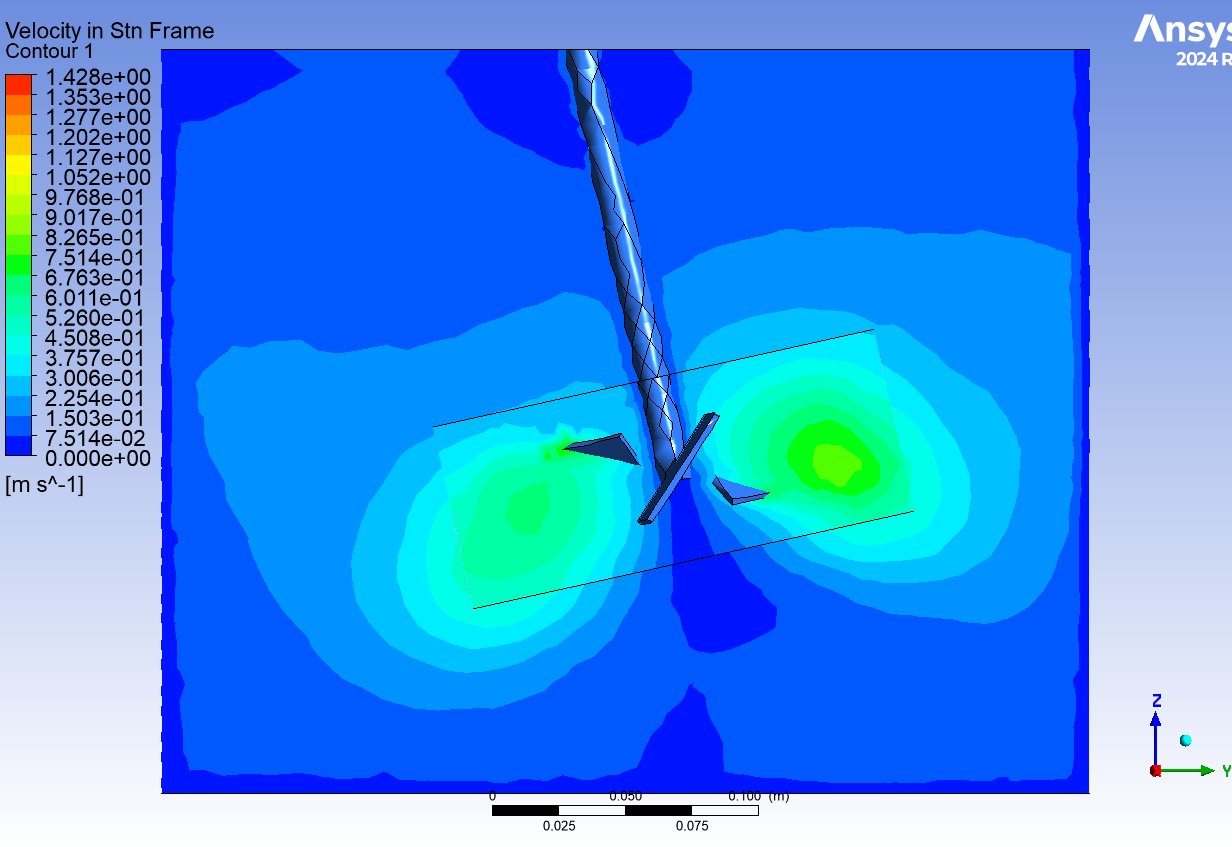

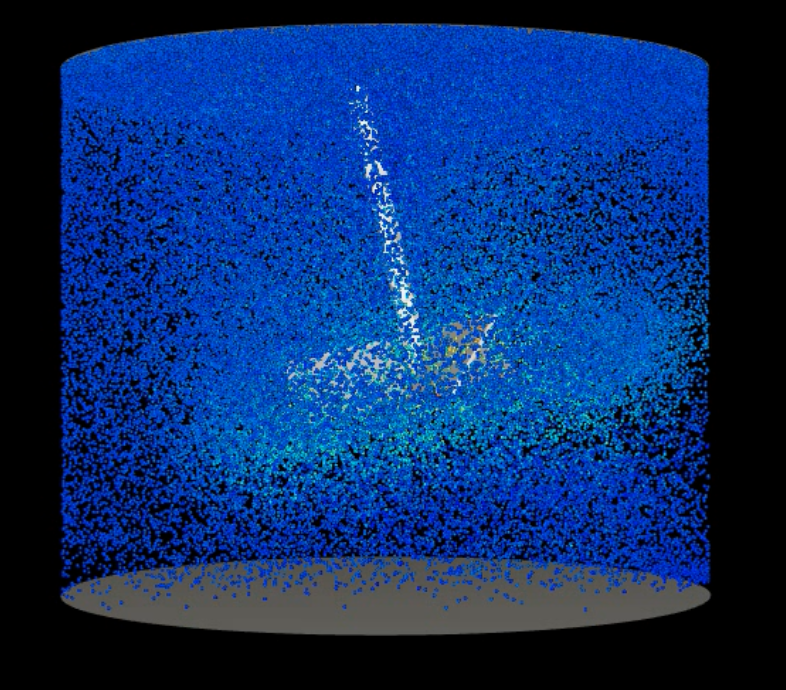

Attached is the velocity contour and Rocky screen shots.

Can you please help me with it ?

viscosity : 100 cp

Viscosity: 1 cp

-

November 26, 2024 at 4:10 pm

Rob

Forum ModeratorYou need to post process over the whole simulation to understand what the flow is doing, and then what the flow is doing to the particles. Increasing viscosity will potentially alter the flow but has a more significant effect on drag. What does your project supervisor/Prof think?

-

November 26, 2024 at 4:19 pm

Saeed

SubscriberOur experiments and the publications in this area shows that for suspensions where particle density is less than fluid, by increasing the viscosity , particle distrubution is less and reduces mixing efficiency.

Do you have any suggustions for this problem ? could altering any Rocky parameters help with the results ?

Thank you

-

November 26, 2024 at 4:25 pm

Rob

Forum ModeratorAs I have no idea what you've set up or how long you've run it for it's somewhat difficult to comment. Have you checked the flow results agree with the experiments, and that all of the properties, boundary conditions etc are the same?

-

November 26, 2024 at 4:36 pm

Saeed

SubscriberYes, all parameters are the same in all simulations. I will explain my set up and I will be grateful if you help me with it.

it is a two-way coupling with CFD time step of 1e-4 and K-e model , production limiter and scalable wall functions are activated. for Dem , possion ratio is 0.25 and young modulus is 1e6 N/M2. material interactions are default. in two way coupling , turbulance disperssion is activated and drag force model is Huilin and Gidaspow. lift force model is Mei. the simulation ran for 10s where it was stable and did not change anymore after 7s. DEM time step is 4.67e-6

Thanks

-

November 26, 2024 at 4:43 pm

Rob

Forum ModeratorAnd the tank size? Impellor speed?

-

November 26, 2024 at 4:44 pm

Saeed

SubscriberThe impeller speed is 20rad/s and tank size is 25 L for all cases.

-

November 26, 2024 at 4:51 pm

Rob

Forum ModeratorHas the system reached equilibrium? Ie have the particles had time to settle/separate? How did you add the particles into Rocky, and how were they added in the experiment?

-

November 26, 2024 at 4:56 pm

Saeed

Subscriberat 7s the system reached equilibrium did not change anymore after that. the particles are added from the top from a circular surface. it was the same for experiments.

-

November 26, 2024 at 5:34 pm

Rob

Forum ModeratorAnd you've confirmed this by...?

-

November 26, 2024 at 5:48 pm

-

November 27, 2024 at 9:54 am

Rob

Forum ModeratorAnd the point data?

Given the number of papers, regression tests etc I don't expect software issues. However, things like convergence, gravity, material properties etc need very careful checking.

-

- You must be logged in to reply to this topic.

-

4858

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.