-

-

November 5, 2024 at 7:34 am

abdullahhassan

SubscriberHello,

I am trying to simulation a shell side condensation with tubeside thermal BC in Fluent.

Initially, i used the simple model to simulate and make the physics right and after achieving good results, i have gone into a little complex geometry.

I have used the VOF-implicit model, k-epsilon and for around 20 30 timesteps(500 iterations), the simulation runs smooth and then reverse flow started in the domain, later after 10 20 timesteps (total of 1000+ iterations), turbulent viiscosity ratio started to appears in the simulation, its increases to a high value and then decreases to zero and repeat again until the solution gets diverge.

1- I have tried to reduce under relaxation factors,

2- Or tried to change the scheme from PISO to Simplec

3- or reduce the timesteps size to min 6e-7 & max 1e-5 with adaptive scheme (multiphase specific) where timestep size = min cell size / velocity is around 3e-5.

4- Tried to change (3 - 4) geometry structure & remesh it and simulate but this turbulent viscosity ratio and divergence is permanent.

5- One thing to note is, the simulation is stable with Eulerian multiphase flow more then VOF but the turbulent viscosity ratio and divergence achieved within 5000-10000 iterations.

I am not sure where is this thing going wrong as the same model works on a simpler geometry very well.

Can you guide me here please.

-

November 5, 2024 at 10:07 am

Rob

Forum ModeratorVOF may be less stable as you're tracking a free surface as opposed to a volume fraction. You may also be building up pockets of liquid to then slug: Eulerian may be more suitable to handle the regime change in the flow.

Stick with PISO, it's better for transient models. I know SIMPLEC has been improved over the years, but still tend not to use it.

Turbulent viscosity ratio is a warning, but may give you some idea of where the problems are being triggered. Have a look at the local flow field.

Simple geometry tends to suggest a simple mesh, and far fewer opportunities for poor quality cells, or poor mesh. A complex geometry typically has regions where things need far more care.

-

November 5, 2024 at 3:31 pm

abdullahhassan

SubscriberThank you Rob,

One thing I need to add: with divergence, sometimes temperature limited to 1.00e1 warning also appears and the divergence happens with divergence detected in AMG solver: k or epsilon or vof and finally Floating point exception error came.

Will these things also highlight to some issues?

Eulerian has Coupled and Phase Coupled Solver and I am trying Phase Coupled Solver right now.

Local Flow Field means checking of velocity vectors inside domain? As the turbulent viscosity is increasing or decreasing so its contour is also changing. how should I know which mesh to improve and from where should i start to improve this divergence?

-

November 5, 2024 at 3:41 pm

Rob

Forum ModeratorWhich is a different warning and may, or may not be caused by the turbulence warning. More likely the energy equation (temperature field) isn't stable and that's causing the rest of the solver to struggle and then fail.

With condensation you're changing phase (fairly obvious). But... That also may result in a large volume change and also large amounts of energy being absorbed or released (latent heat). If the time scale of condensation isn't being captured or you're trying to add too much liquid/vapour to a small cell things can begin to go wrong. Hence looking at contours of temperature, phase, velocity etc inside the domain. You need to see where problems are coming from, and from that figure out what needs changing to obtain a good result.

-

November 7, 2024 at 9:24 am

abdullahhassan

SubscriberHello Rob,

So, I have checked the warning issues further by checking temperature, velocity, turbulent viscisity ratio contours at 450 iterations and 600 iterations and I think the problem is the outlet of the shell side.

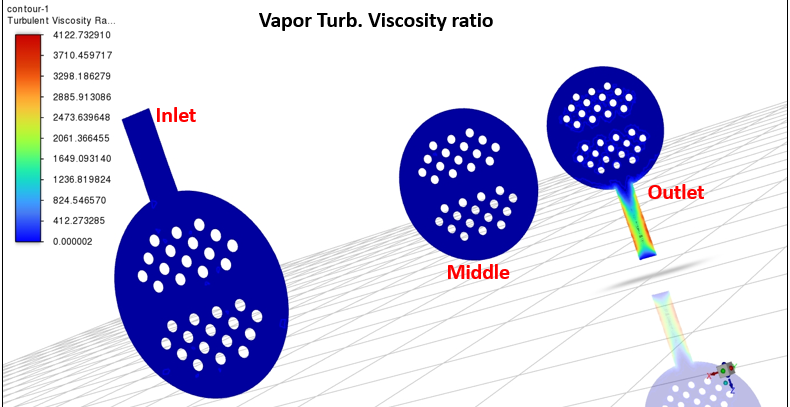

At 450 iterations, turbulent viscosity ratio was limited to less then 10 cells. Below are the turbulent viscosity ratio contour at inlet, middle and outlet of shell side.

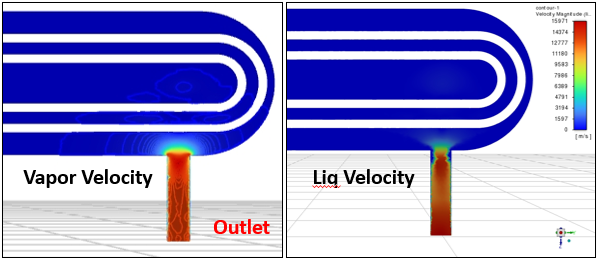

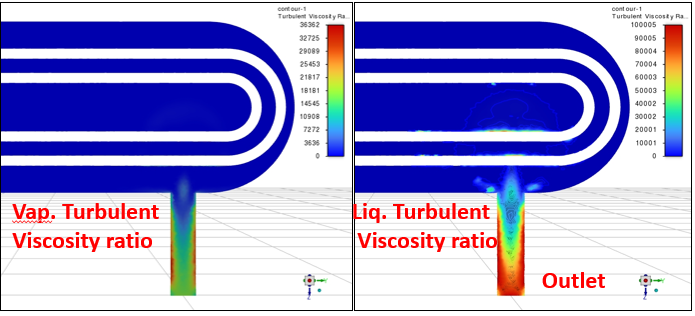

at 600 iterations, turbulent viscosity ratio increases to almost 2700 cells. below are the liqud & turbulent viscosity ratio contours and Liq. Turbulent Viscosity reaches 1e5 limit.

Do I need to improve the mesh at the outlet, I have drawn polyhedra mesh with zero inflation near shell wall.

Or I need to increase the length of the outlet?

What do you think on that?

-

November 7, 2024 at 3:29 pm

Rob

Forum ModeratorWhat is the backflow setting on the outlet? If you have phase change on the shellside where does the vapour go?

-

November 8, 2024 at 1:29 am

abdullahhassan

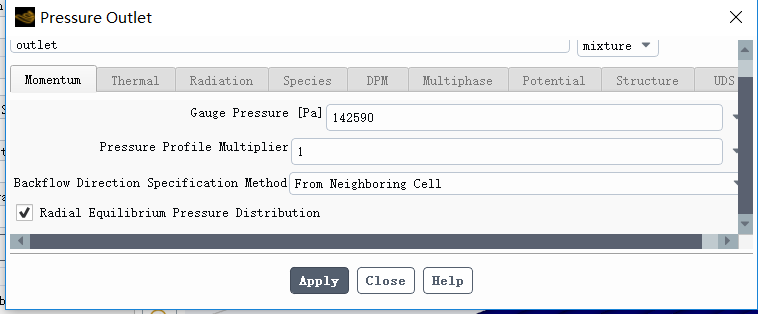

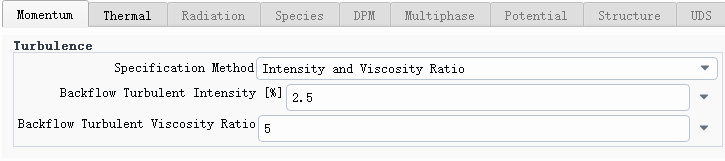

SubscriberThe outlet conditions are:

Pressure (Lower then inlet pressure) , Backflow VF for both liquid & vapor = 0

Backflow Direction: I tried to solve with normal to boundary but then alot of liquid starts to come back from outlet. so i choosed From Neighboring Cells.

backflow turbulence is same for liquid and vapor.

-

November 8, 2024 at 10:28 am

Rob

Forum ModeratorHow can backflow for liquid AND vapour be set as zero?

-

November 8, 2024 at 4:31 pm

abdullahhassan

SubscriberOoh. You are right.

But I didn't put liquid as a backflow due to the fact the majority of the vapor is going out of the domain. so i thought, it might confuse software. but yeah i didn't give it a try. I will give it a try now.

for vapor, I want maximum condensation so that's why i didn't put vapor as a backflow.

-

November 8, 2024 at 4:40 pm

Rob

Forum ModeratorI usually am..... ;)

Except that with vapour as the backflow fluid you're fighting buoyancy on the outlet.

-

- You must be logged in to reply to this topic.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Issue to compile a UDF in ANSYS Fluent

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

- Continuing SAG Mill Simulation with New Particle Batch in Rocky

-

4512

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.