-

-

July 29, 2024 at 12:08 pm

-

July 29, 2024 at 12:44 pm

Armin

Ansys EmployeeHi Ji,

Could you describe more about your model, like how and where the forces are applied as well as any other boundary conditions utilized in the model?

-

July 29, 2024 at 1:29 pm

1617836513

SubscriberHi,

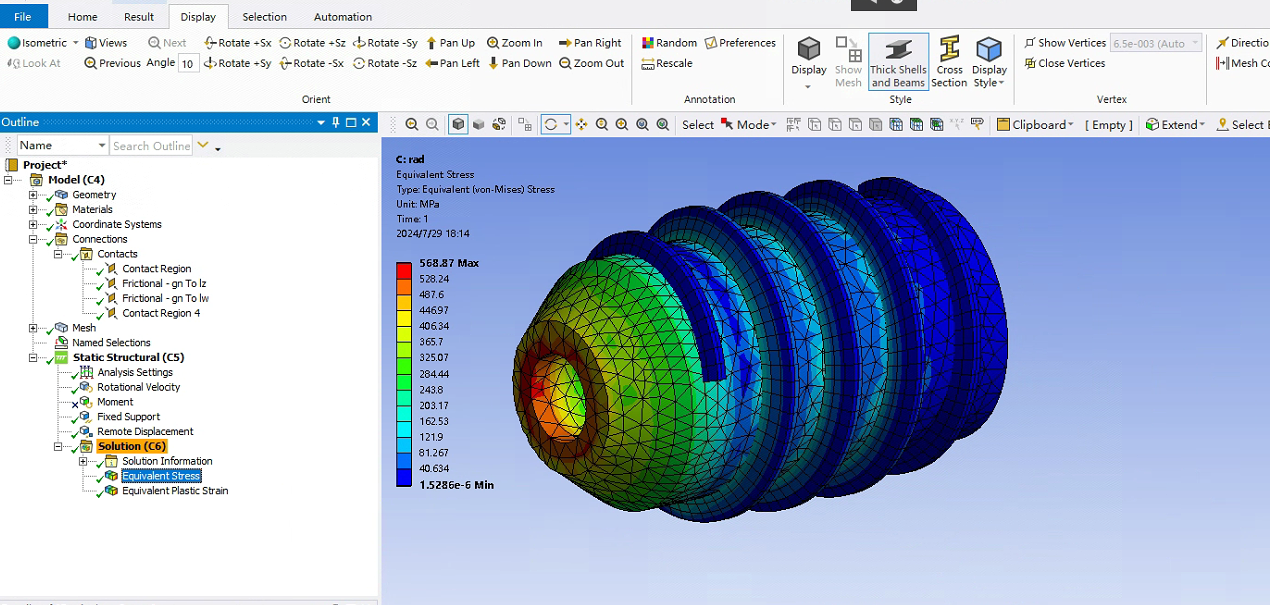

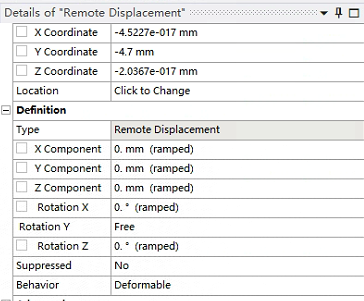

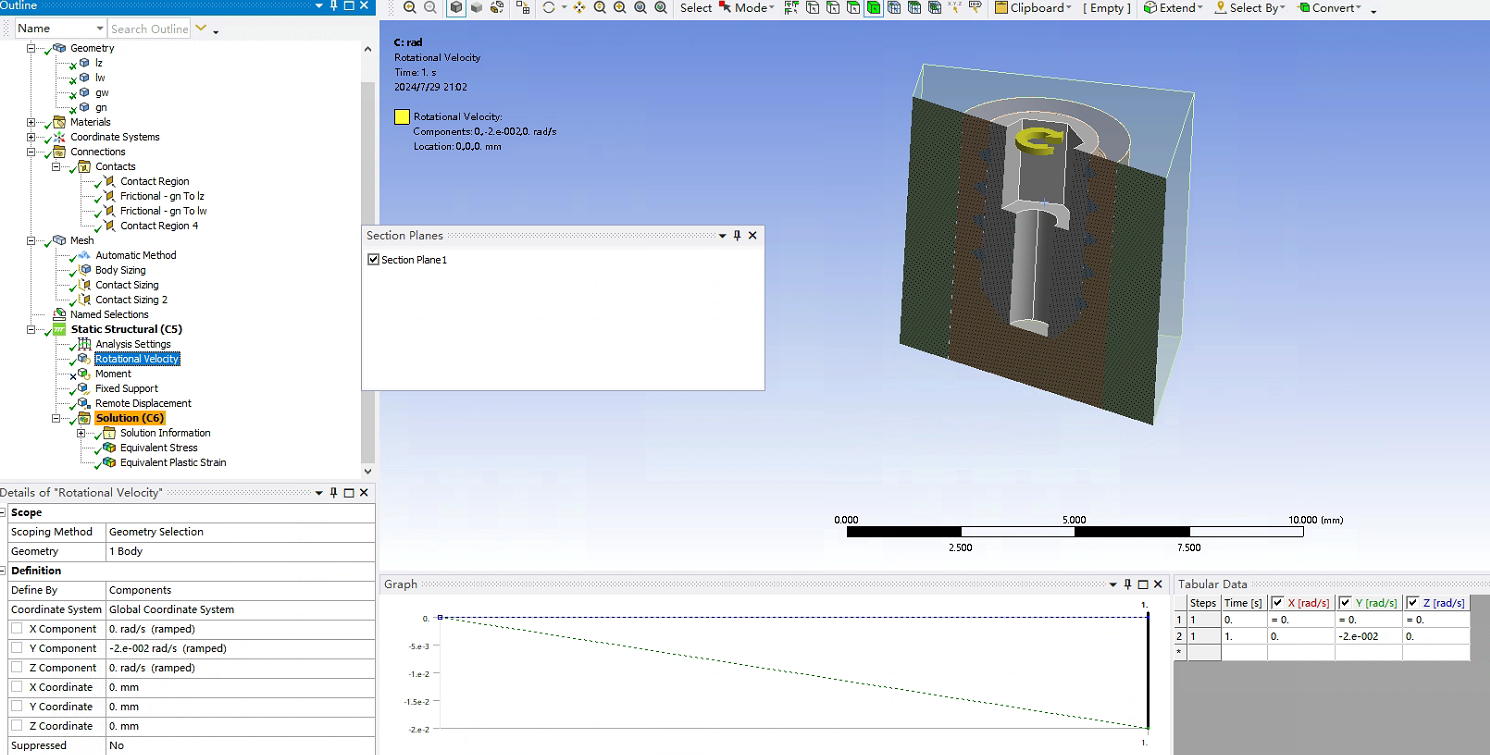

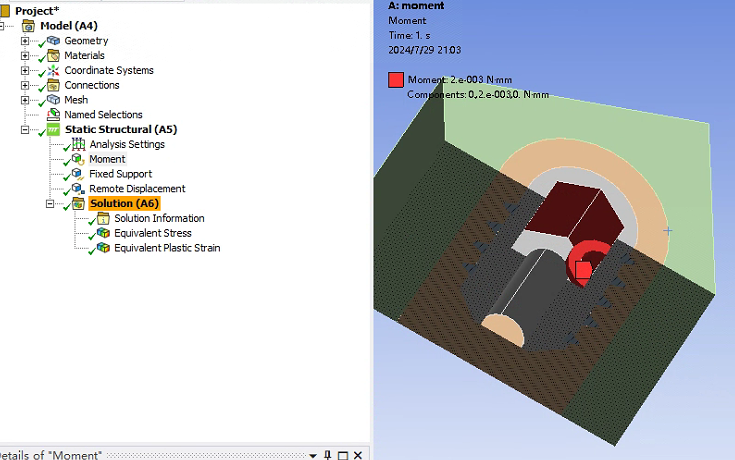

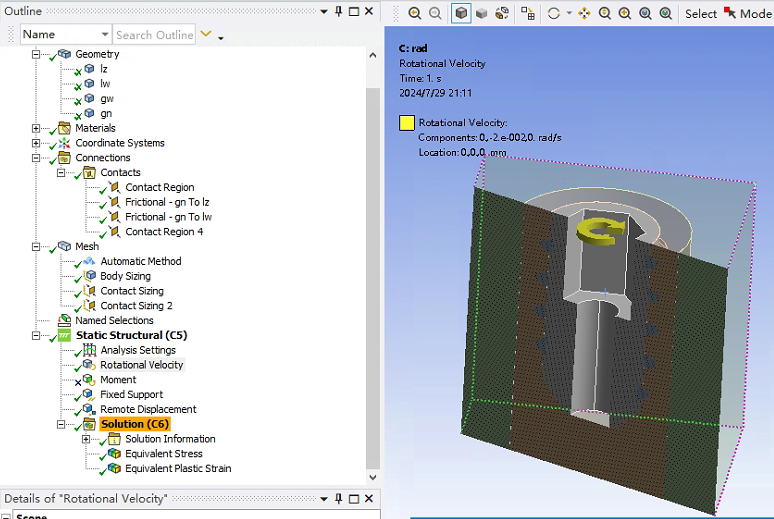

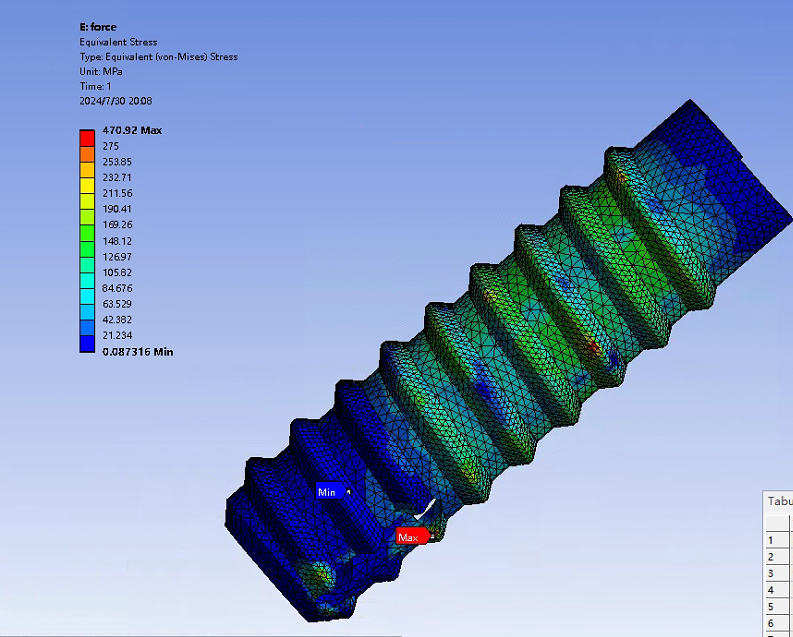

I am trying to simulate a stress analysis of a screw screwed into a piece of bone. The constraints are to fix the bottom of the bone and allow rotation around the y-axis at the bottom of the screw. I first set a torque of 2N/m on the six internal surfaces of the screw and the results are shown in the figure. After that the other conditions did not change and I changed the torque to apply 0.02 rad/s to the screw as a whole, but the results did not change . Until I changed the normal contact stiffness from 0.5 to 0.1 and the stress maximum from 556MPa to 568MPa.

-

-

July 29, 2024 at 1:14 pm

1617836513

SubscriberI am trying to simulate a stress analysis of a screw screwed into a piece of bone. The constraints are to fix the bottom of the bone and allow rotation around the y-axis at the bottom of the screw. I first set a torque of 2N/m on the six internal surfaces of the screw and the results are shown in the figure. After that the other conditions did not change and I changed the torque to apply 0.02 rad/s to the screw as a whole, but the results did not change . Until I changed the normal contact stiffness from 0.5 to 0.1 and the stress maximum from 556MPa to 568MPa. -

July 29, 2024 at 1:48 pm

Armin

Ansys EmployeeThank you. Here are a few suggestions:

- To verify whether the torque magnitudes are being updated as a result of changing the Rotational Velocity, you can examine the reaction moments at the Fixed Support (drag-and drop Fixed Support onto the Solution branch after the solution is complete).

- I'm not sure if the Remote Displacement is necessary in your case since the screw appears to be well-constrained within the bone.

- Is your goal to simulate the whole screwing process with the screw penetrating into the bone? If so, explicit dynamics analysis, using Ansys LS-DYNA for example, might be a better option than the current implicit solution.-

July 30, 2024 at 3:59 am

1617836513

SubscriberOkay, thank you very much for your advice. I would also like to ask again, inside this self-designed screw simulation, such as screwing in a screw, or pulling out a screw, do I need to consider adding bolt pretention? If so, how do I set the amount of bolt pretention?

-

-

July 30, 2024 at 1:24 pm

Armin

Ansys EmployeeNo problem Ji. If I'm not mistaken, you're simulating the whole screwing process so the pre-load is expected to be developed in the screw as an outcome of the simulation, but if you're interested about the bolt pre-tension object in Ansys Mechanical, please check the following document: https://innovationspace.ansys.com/courses/wp-content/uploads/2020/10/2.2.3_Bolt-Pretension-Object_new_brand.pdf

-

July 30, 2024 at 3:18 pm

1617836513

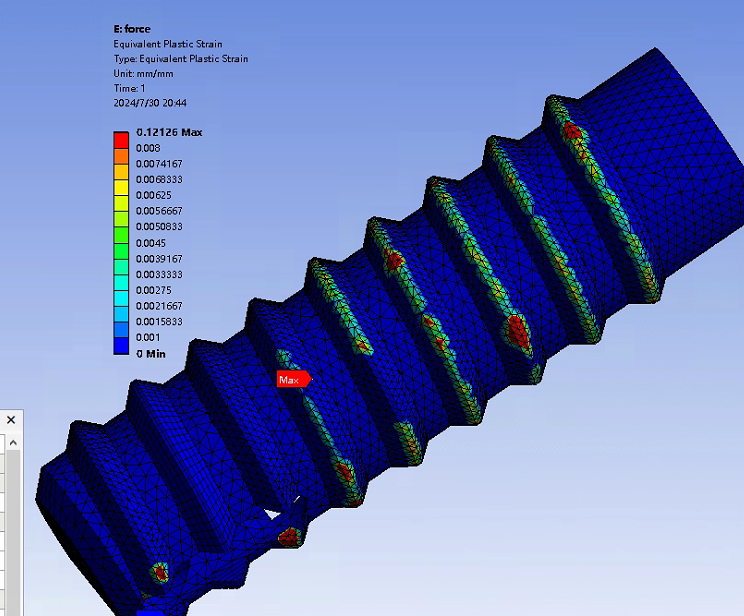

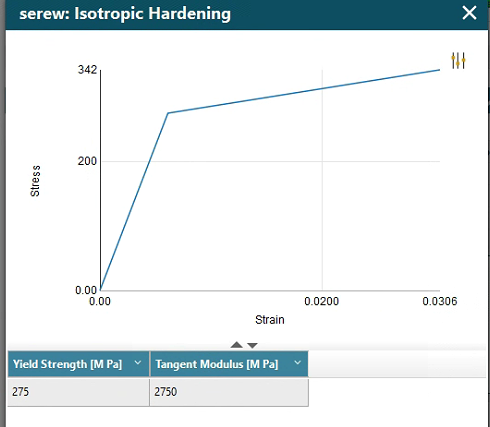

SubscriberThank you! May I ask why I have plastic deformation in this model in some areas where the stress does not reach the yield strength? The yield strength is 275MPa, and how can I see the stresses at Gaussian points in workbench? I am new to finite element simulation, so please forgive me for asking such a simple question.

-

July 30, 2024 at 3:52 pm

Armin

Ansys EmployeeNo worries, I just responded to your other post about plastic deformation.

Stress is calculated at the integration points and then extrapolated to the nodes. What you see reported in Mechanical is the averaged values of stress at each node. For a detailed discussion on this topic, please see the (long) thread below: https://innovationspace.ansys.com/forum/forums/topic/integration-point-results-option-in-equivalent-stress/ -

July 30, 2024 at 4:46 pm

1617836513

SubscriberArmin, thank you very much!

-

-

August 2, 2024 at 1:20 am

1617836513

Subscriberhi, can you tell me in the simulation of bolt preload, a torque is applied to the bolt, how to set it to output the preload of the bolted connection

-

-

- The topic ‘why calculations are the same for different load sizes or types’ is closed to new replies.

-

4838

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.