-

-

July 16, 2024 at 5:26 am

-

July 16, 2024 at 2:16 pm

Ashish Khemka

Forum ModeratorHi,

I am assuming that the discrepancy is due to difference in material model/ modeling technique between the two. If you can elaborate on what you mean by ACP method then it might help to comment further.

Regards,

Ashish Khemka

-

July 24, 2024 at 4:06 am

Ro.hi

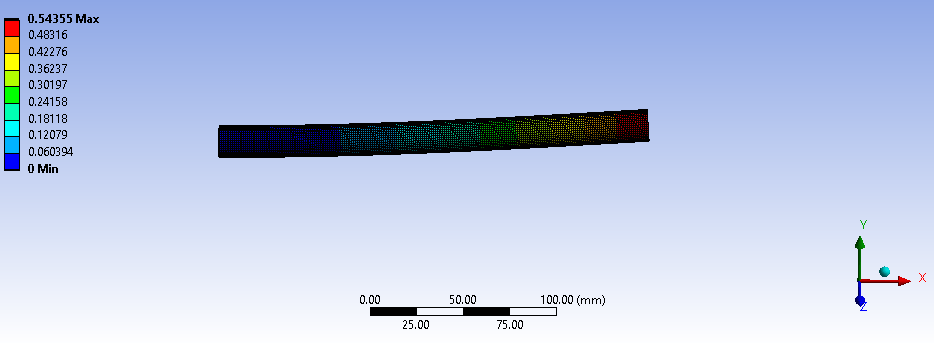

SubscriberBasically, I have two hollow tube for bending testing and their dimension is same OD=16; ID=14& L=230mm. I try to simulate the tube under two methods Static Structural and ACP pre.

In static structural, I applied material as Epoxy carbon woven (230Gpa) Wet. And I fixed one end of the tube and appling the force(9.81N) on the other end.

And, In ACP-pre i tried to appling the 5-types of layer for laminating under 0°,45°,90°,-45°,0° and the thickness is 0.2mm per layer. After all process, I share file to Static Structural path.then I follow the same instruction for previous static structural way.

-

- The topic ‘Static Structural vs ACP pre’ is closed to new replies.

-

4607

-

1510

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.