-

-

June 5, 2024 at 5:38 pm

javat33489

SubscriberProblem with tension, SPG mesh and fatigue

Hi all. I previously published a topic:

/forum/forums/topic/problems-with-fatigue-calculations/

about fatigue analysis, there were a number of problems with outcome indicators such as fatigue life and fatigue cycles.

The topic has dragged on and become confusing. Since then, I found a clue to the problem and would like to post it in a separate post, maybe someone will have a similar problem. It will be easy to find the answer.So here it is. I made some interesting observations.

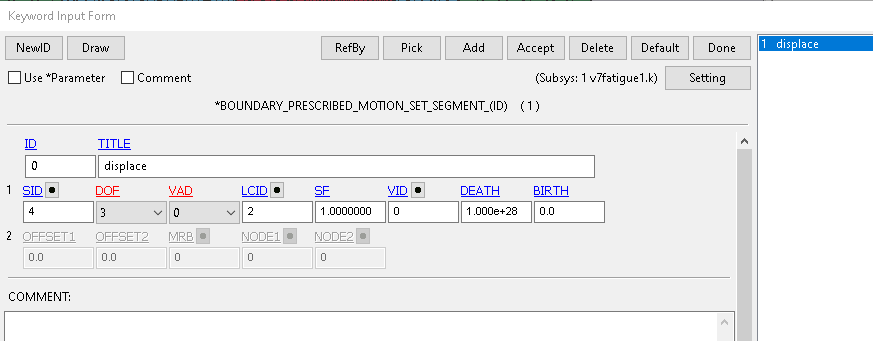

When calculating the fatigue of drilling a concrete slab, I removed the rotation and included only the downward movement to simplify the task and clearly see what is happening with the drill, because The area being examined is a drill.

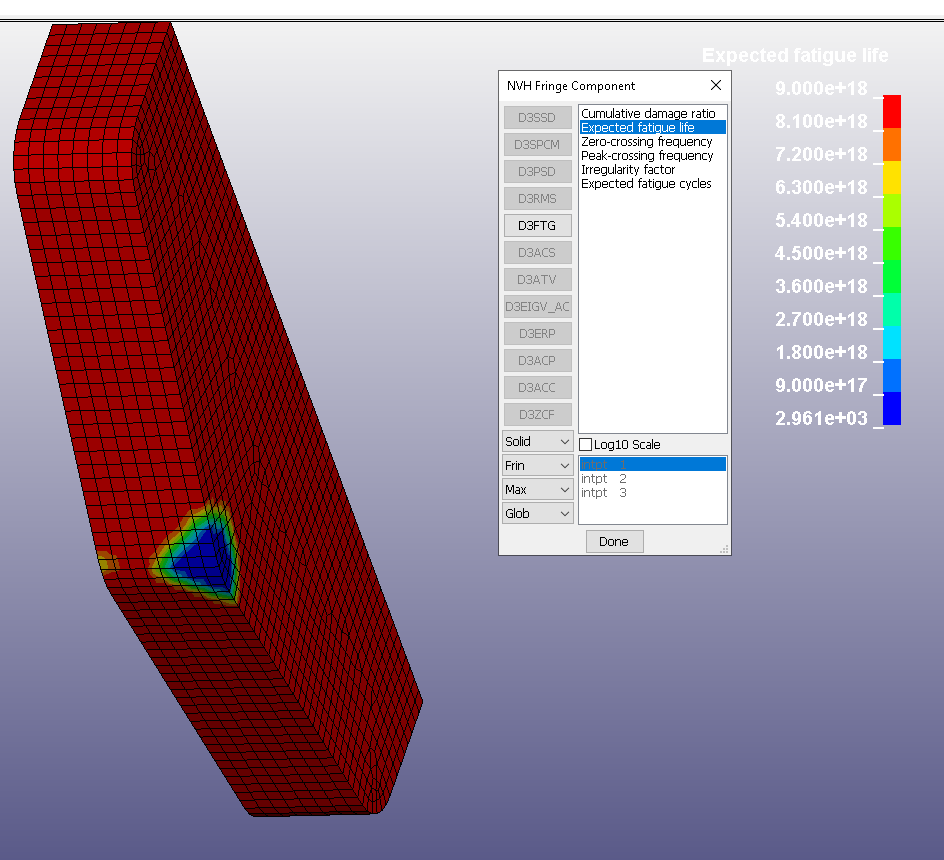

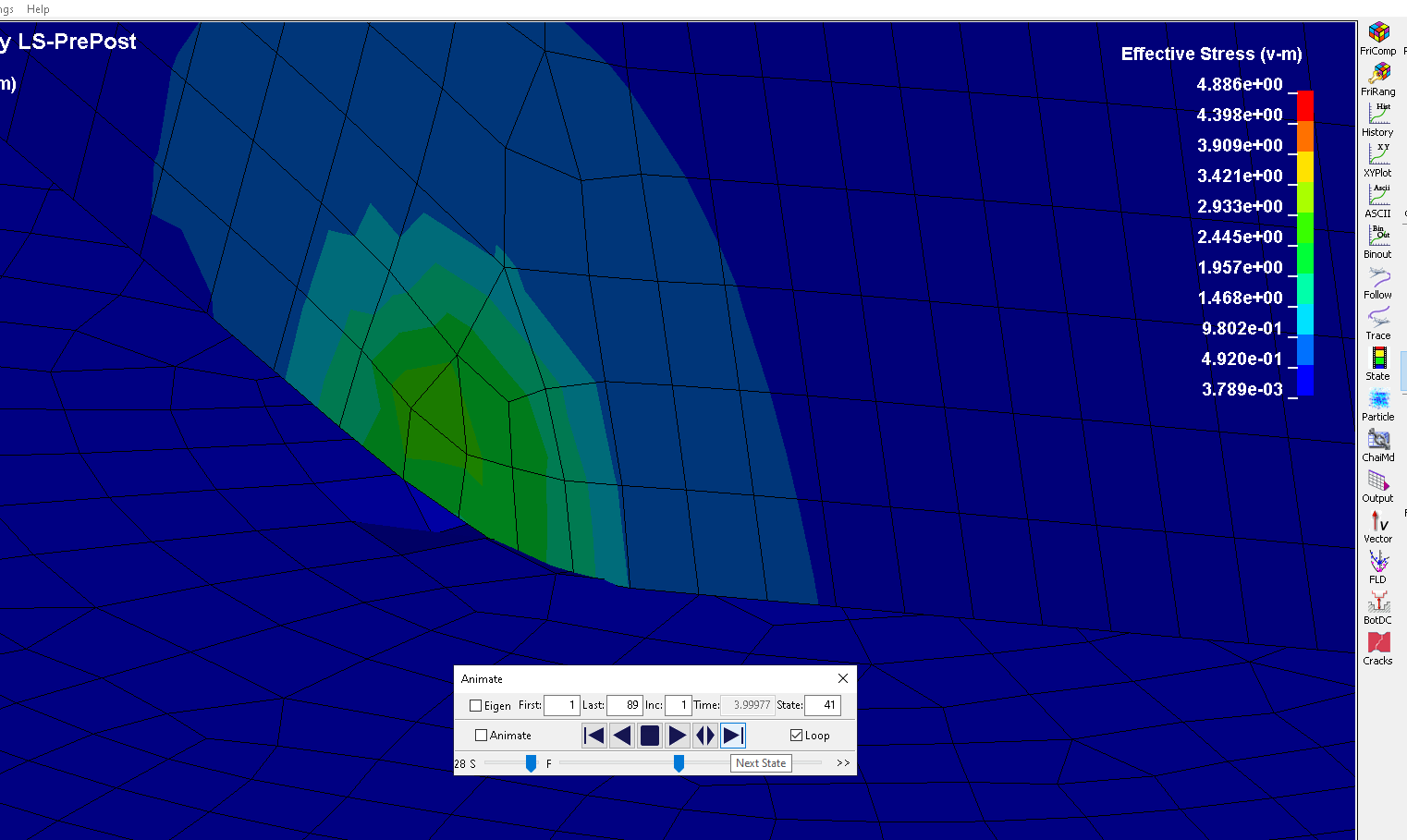

The drill is pressed into the die. For some reason, the voltage is only on one side of the drill:and therefore fatigue life is also greatly reduced in this area.

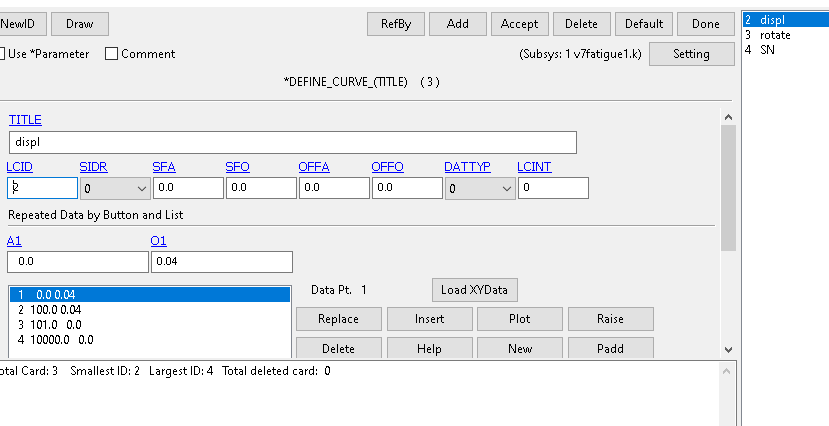

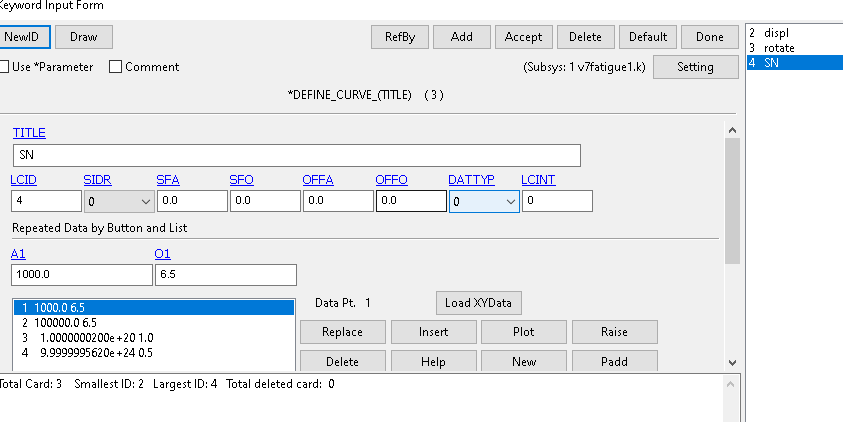

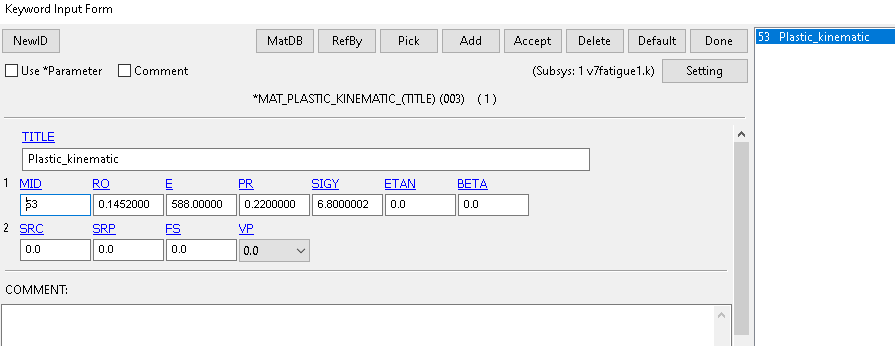

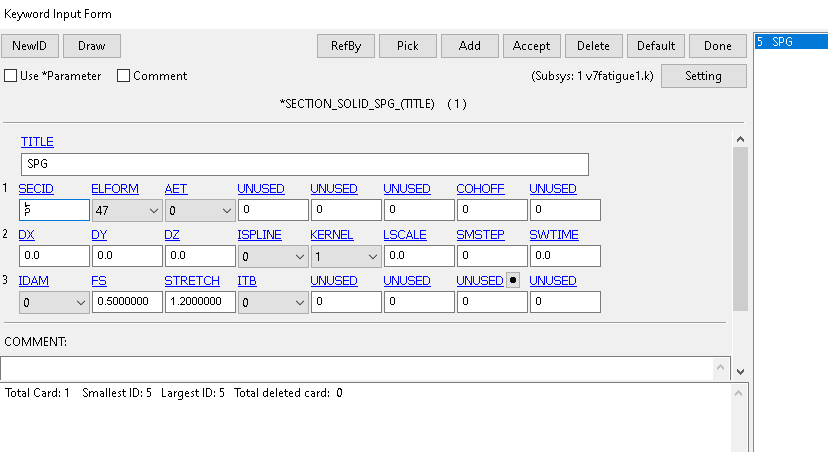

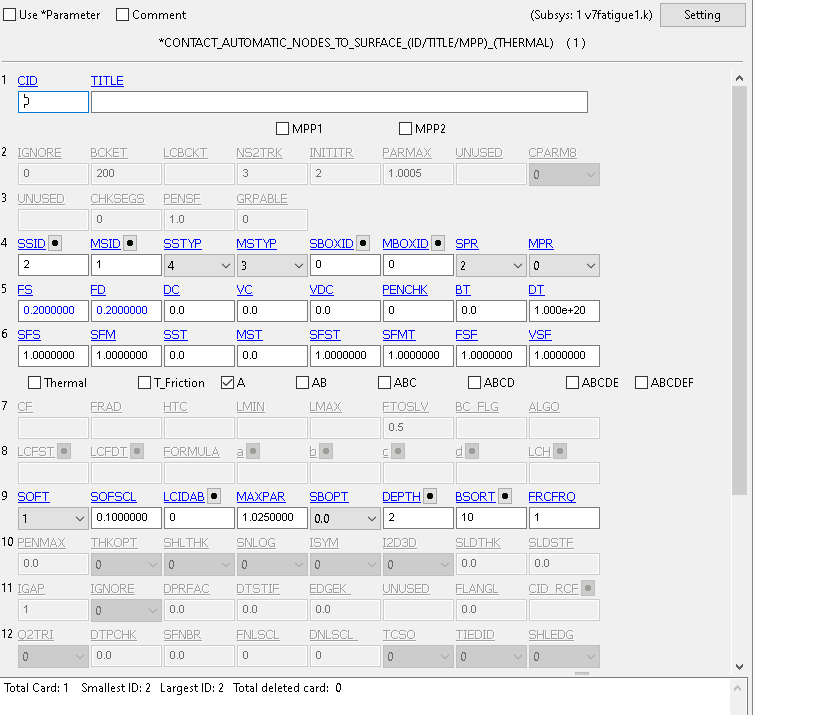

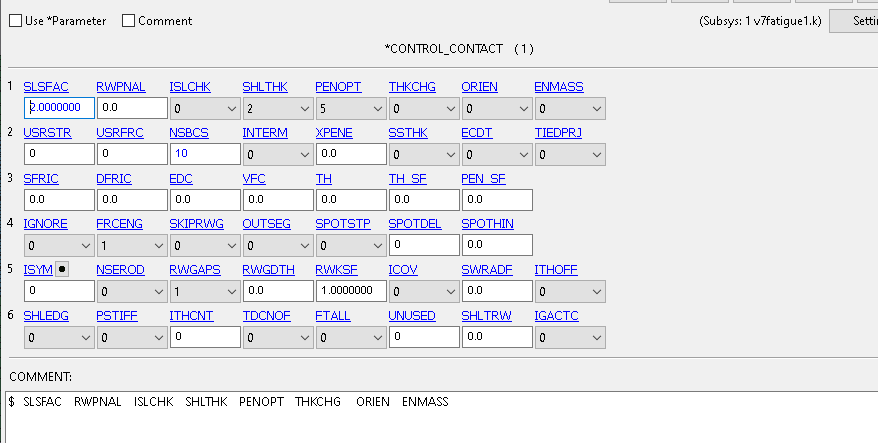

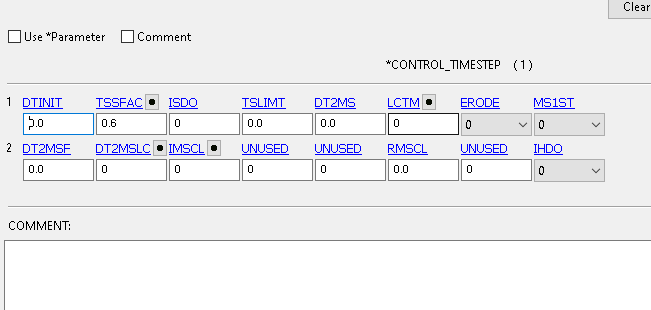

I use the following settings for material, movement, SN, analysis and contact:

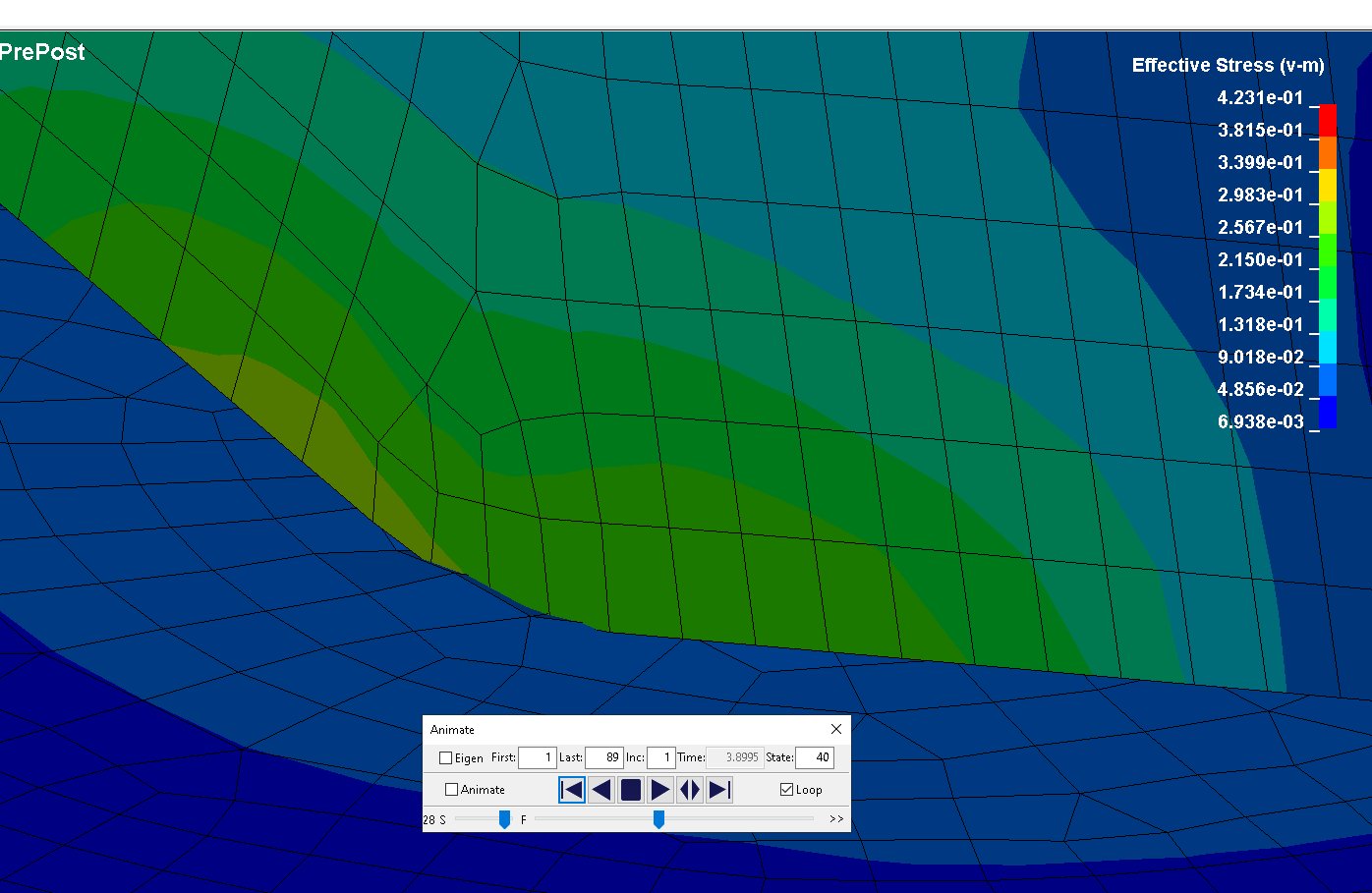

Then I began to look at each step of the drill’s movement and noticed that at step 40 everything was still good, the stresses were symmetrical, but at step 41, the mesh on the surface of the die seemed to break or turn inside out and the stresses on the drill sharply concentrated in one place, and so on until the end of the calculation:

Could this behavior of the mesh be the reason that the stresses turn into a concentrator and that is why when performing fatigue calculations there is the weakest point?

I assigned the SPG material to the die via a section. Why does the program pay attention to this strange grid behavior? Can this be disabled for SPG? -

July 8, 2024 at 3:44 pm

Ram Gopisetti

Ansys EmployeeHi,

SPG operates on the background FEA mesh. In areas prone to erosion or where contact occurs, the mesh needs to be finer. Additionally, the SPG solution should be presented as particles rather than a mesh.

The SPG card parameters used are incorrect, especially in lines 4 and 3. It's recommended to use coupling_spg_to_surface cards for the contact.

For drilling applications, we typically use SMSTEP = 5, IDAM = 5, KERNEL = 1, DX, DY, DZ = 1.8. ITB can be set to 3 or 1. Please note that fatigue may not be considered for SPG.

Cheers, Ram

-

- The topic ‘Problem with tension, SPG mesh and fatigue’ is closed to new replies.

-

4728

-

1565

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.