Ansys Learning Forum › Forums › Discuss Simulation › LS Dyna › Metal forming (spinning) › Reply To: Metal forming (spinning)

I'm very sorry for not explaining this issue clearly.

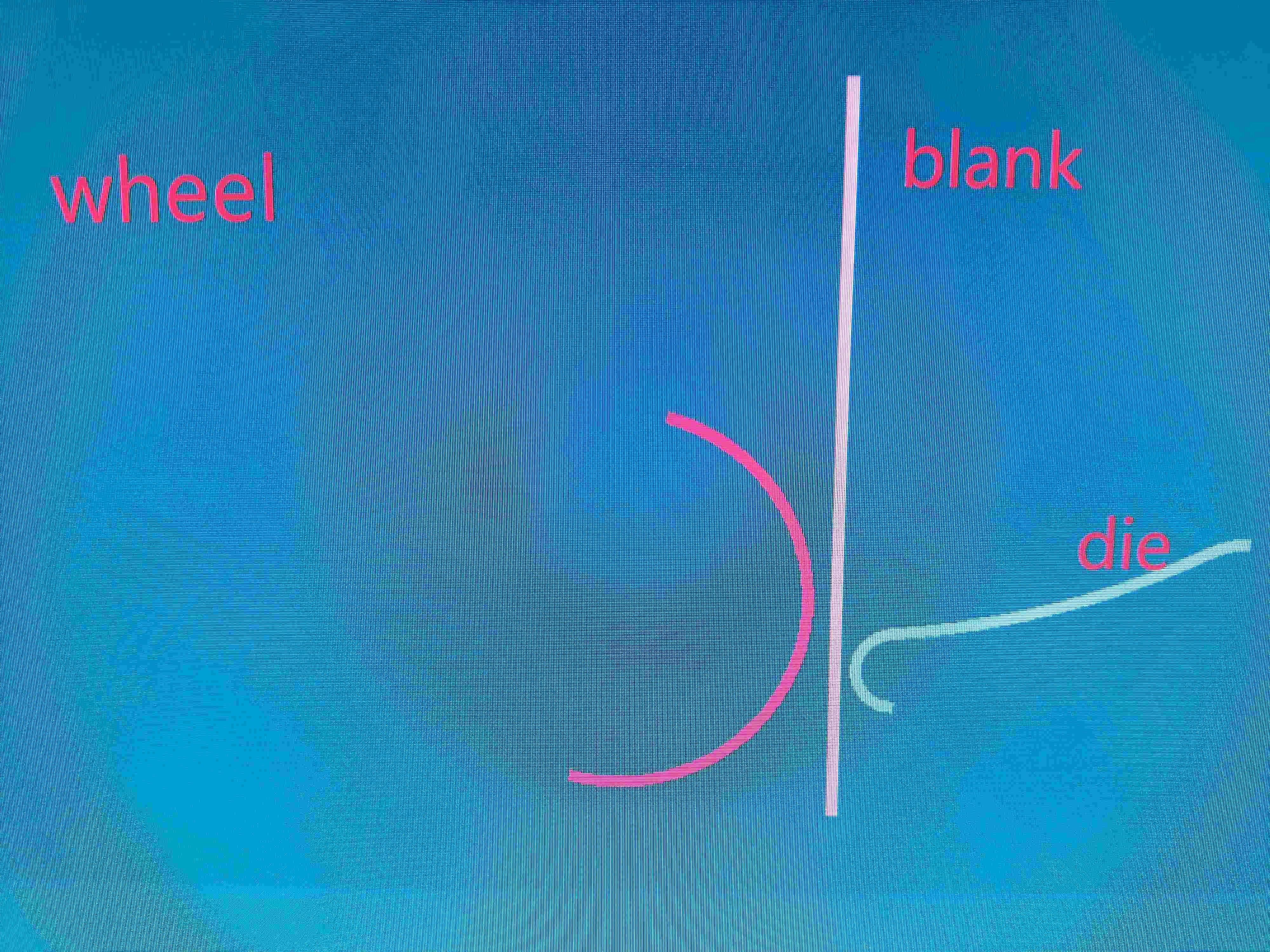

Working condition: Blank and die are connected by *Constrained_EXTRA_NODES-SET. The blank is formed through multiple processing steps by wheel.There are some issues here.

SECTION A:

1、Normal circumstances:Rotating wheel speed 628 rad/min (100r/min), wheel feed rate 40mm//min. The following is the result of my simulation.

This is a normal phenomenon.

2、However, When I adjusted the speed of the die to 3140rad/min (500r/min), the wheel speed remains constant. After being in contact with the wheel for a period of time, the blank detached from contact with the spinning wheel and deformed itself.( Blank,-press down on his own) This is seriously divorced from the facts.

3、At that time, I thought the speed was given too fast, so I maintained a speed of 628 rad/min (100r/min), The wheel speed has been slowed down to 8mm/min. But there are still issues with situation 2, except that the amplitude of deformation of the sheet metal itself decreases.

4、At 500r/min, the blank showed outward drift, but the experimental blank did not show any outward drift. Why does this phenomenon occur ?

I want to know, Wheel, without putting pressure on Blank, What is the reason for Blank's own deformation. At present, I speculate on my own whether it is related to dynamic relaxation phenomenon.But this problem has been bothering me for a long time and has not been solved yet.