-

-

May 16, 2024 at 9:42 am

Antonio Sola

SubscriberHello!

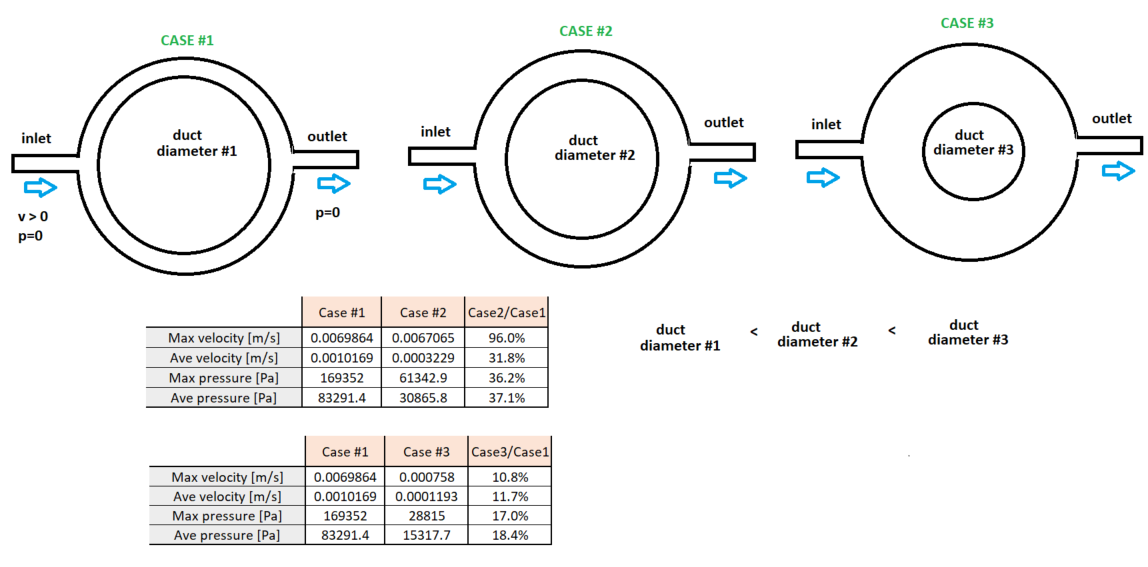

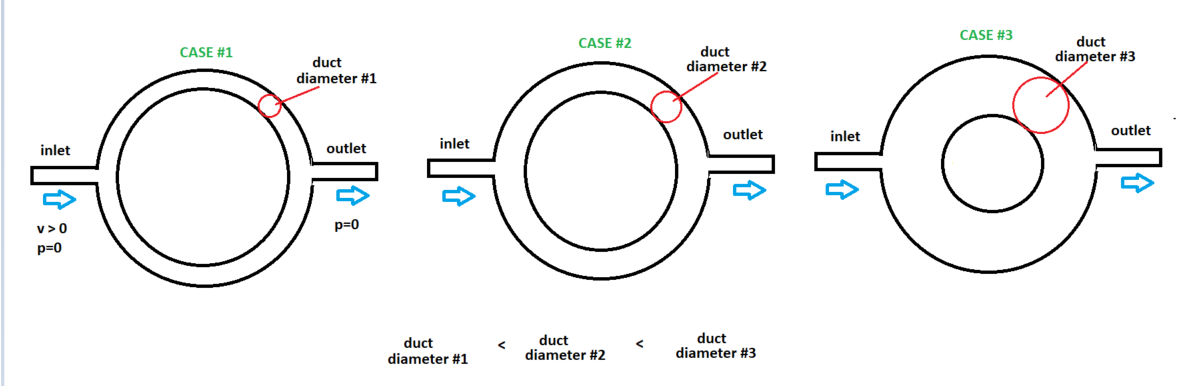

I'm simulating a laminar flow crossing a device in different cases (with modifications of its internal geometry).

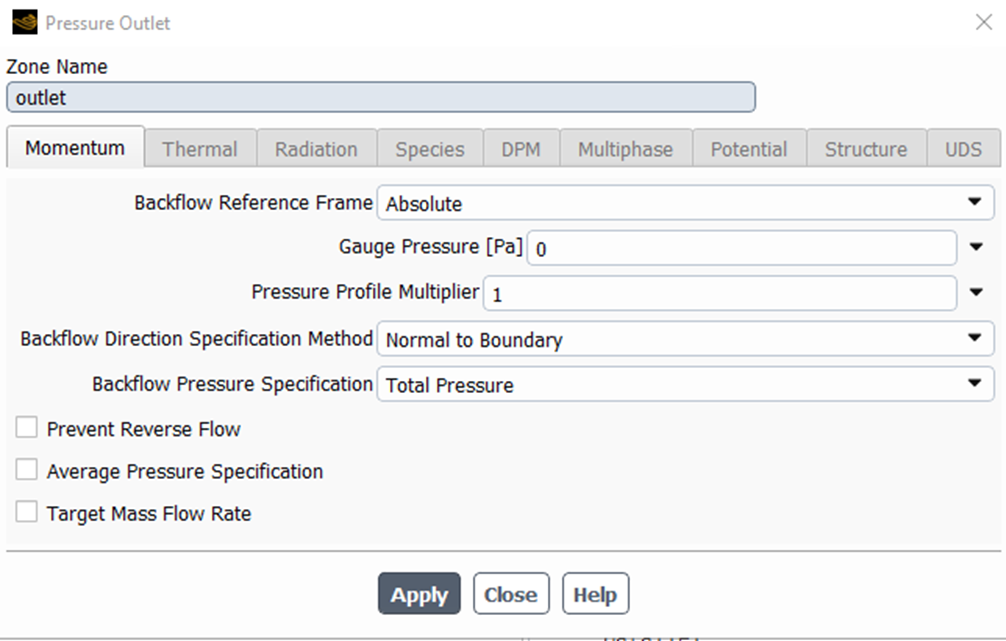

In case of a widening of the ducts of the internal geometry, the average velocity tends to decrease (It has sense because the diameters of the ducts are bigger). But the average pressure results show also the pressure tends to decrease and I don't know if it has sense, considering the pressure should increase with the widening of the ducts... The boundary condictions are: inlet velocity>0; inlet pressure=0; outlet pressure=0, for all cases.

My question is: what type of pressure measure Fluent? and, has it sense the pressure and the velocity decrease at the same time?

In a third case, with already bigger ducts, the effect is the same: average velocity and also pressure of the flow decrease...

Here is the system schematically:

Thank you in advaced.

-

May 16, 2024 at 11:12 am

Rob

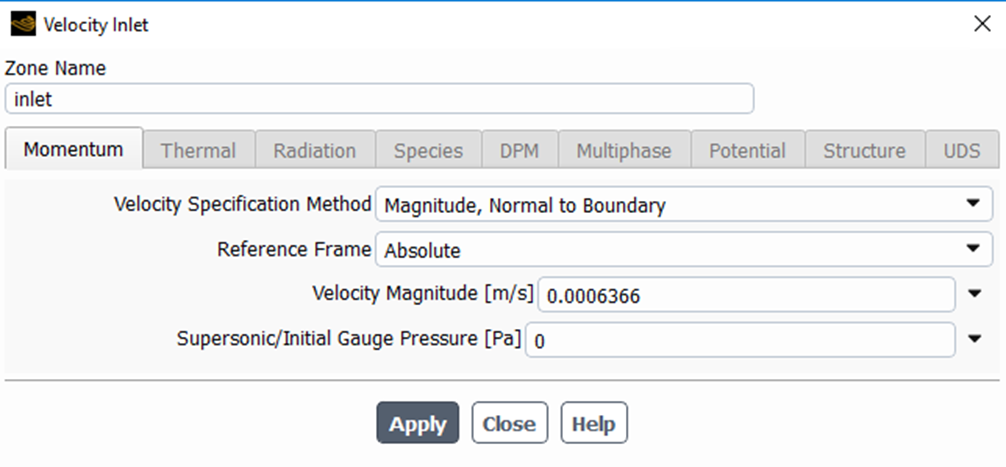

Forum ModeratorWhat are you setting on the inlet in each case?

-

May 16, 2024 at 12:40 pm

-

-

May 16, 2024 at 4:11 pm

Rob

Forum ModeratorThat's fine. Why would pressure loss increase with a wider duct? Be wary of maximum values without checking where those values are. If you check the area average on the inlet how does it compare across the cases? How do the velocity & pressure contours look?

-

May 20, 2024 at 10:58 am

-

May 20, 2024 at 11:00 am

Antonio Sola

SubscriberAt any point of the domain the behaior is the same.

-

May 20, 2024 at 11:12 am

Rob

Forum ModeratorSo as the annular flow channel becomes larger the overall pressure loss decreases.

-

May 20, 2024 at 12:13 pm

Antonio Sola

SubscriberExactly

-

May 20, 2024 at 1:21 pm

Rob

Forum ModeratorI'm lost - in the original post you thought the loss shouldn't decrease?

-

May 20, 2024 at 1:29 pm

Antonio Sola

SubscriberSorry.

So as the annular flow channel becomes larger the overall pressure loss increases. That is the point.

-

May 20, 2024 at 1:54 pm

Rob

Forum ModeratorBut in the images the flow channel is smallest in #1 ? Please post some Fluent results images.

-

May 21, 2024 at 10:06 am

Antonio Sola

SubscriberBeginning again... We have three cases:

Essentially are the same (same inlet and outlet channels diameters, same initial velocity at the inlet).

The unique difference is the diameter of the circular internal duct (circular duct diameter of case #1 is the smallest).

The problem I see is that increasing the diameter of the internal circular duct, the average pressure is smaller (when I think should be bigger, because the velocity should decrease and the pressure increase).

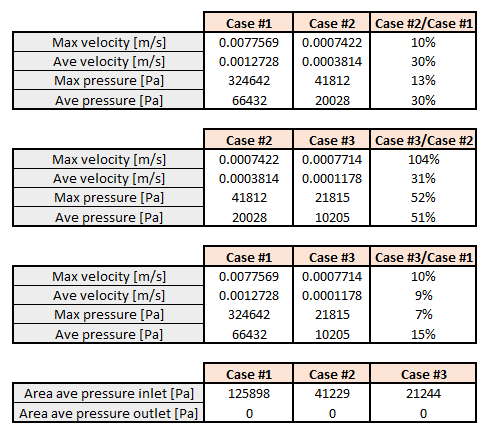

Here are new relations between the values gotten in the different cases:

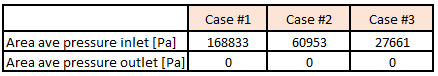

As we can see, the average pressure decrease when circular duct diameter is bigger (it doesn't have sense for me).

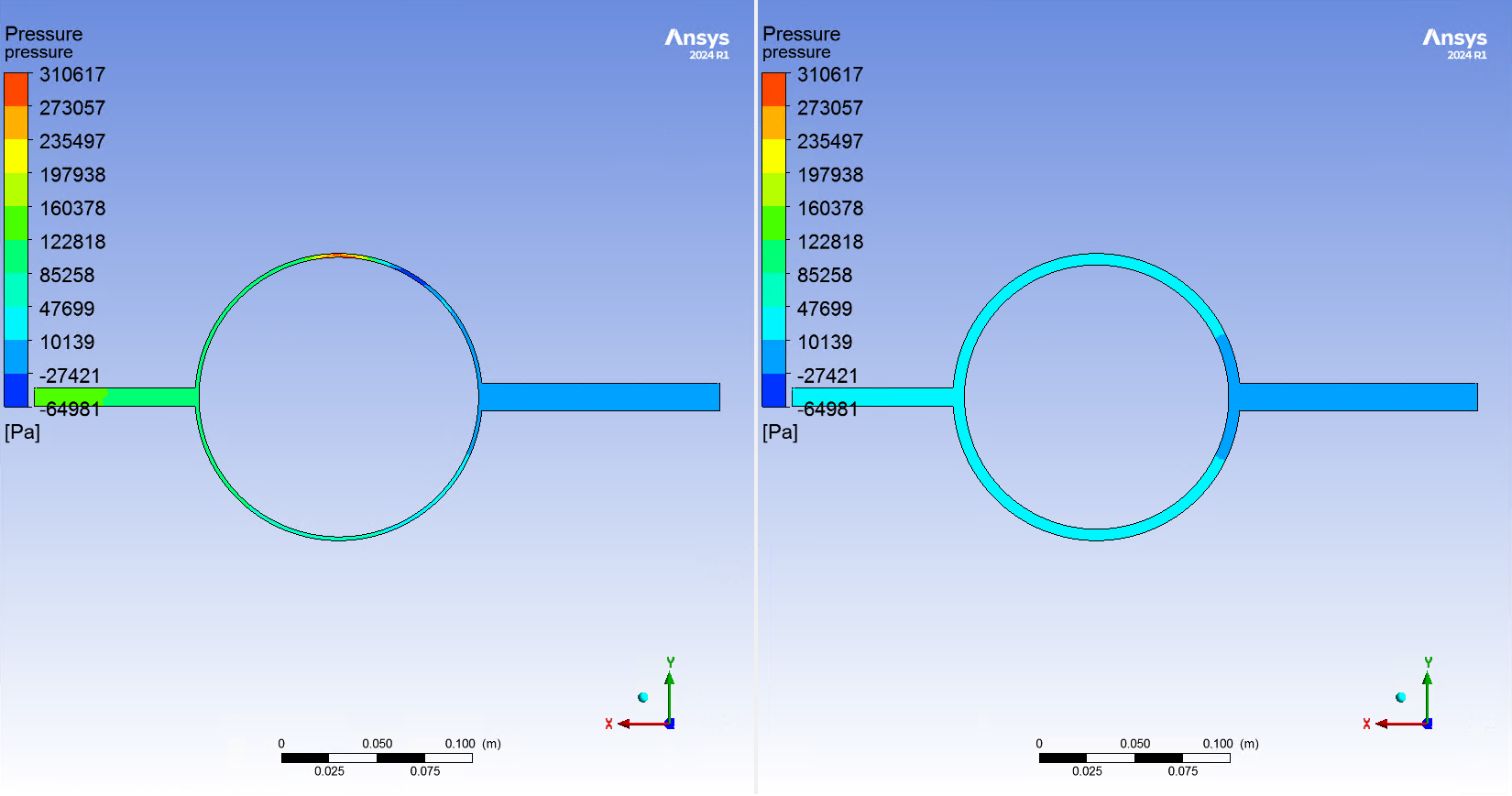

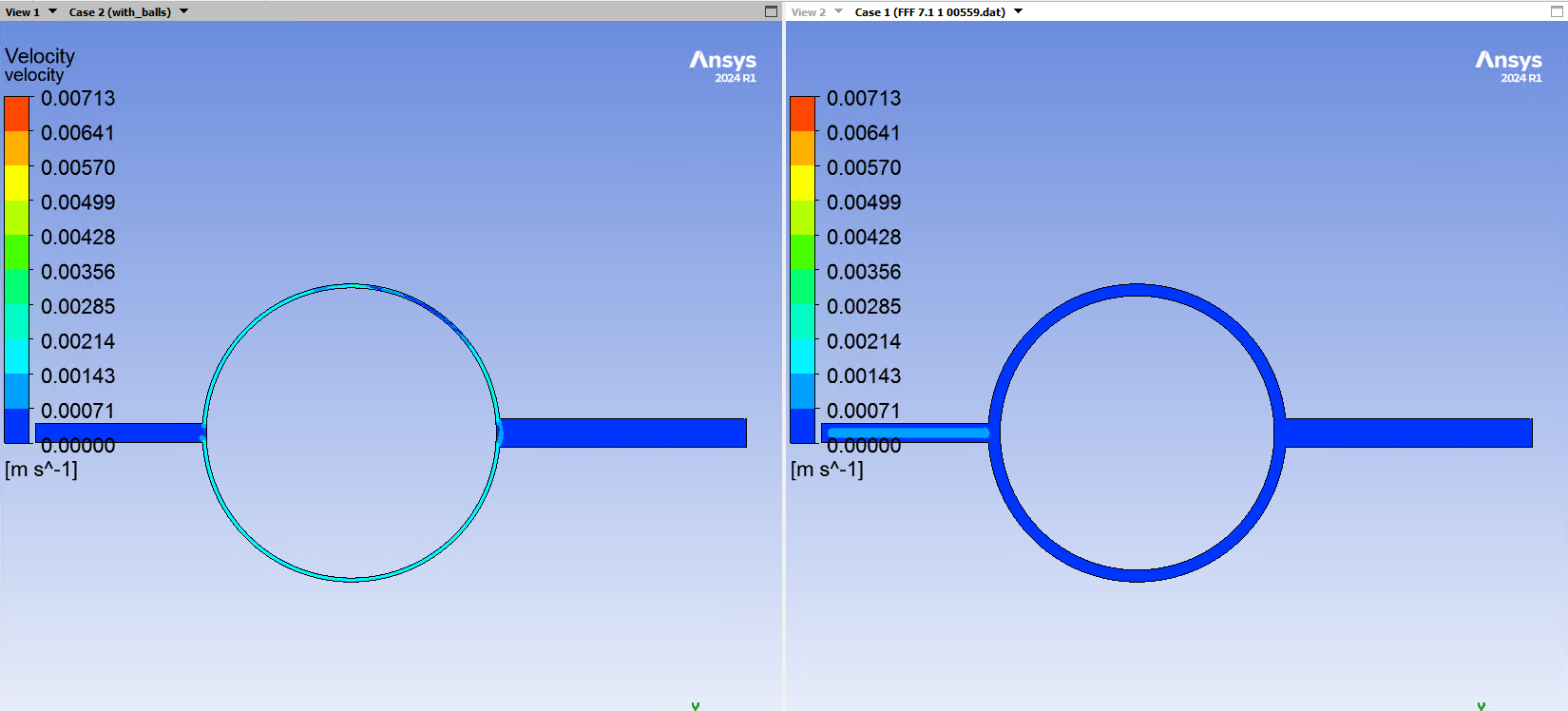

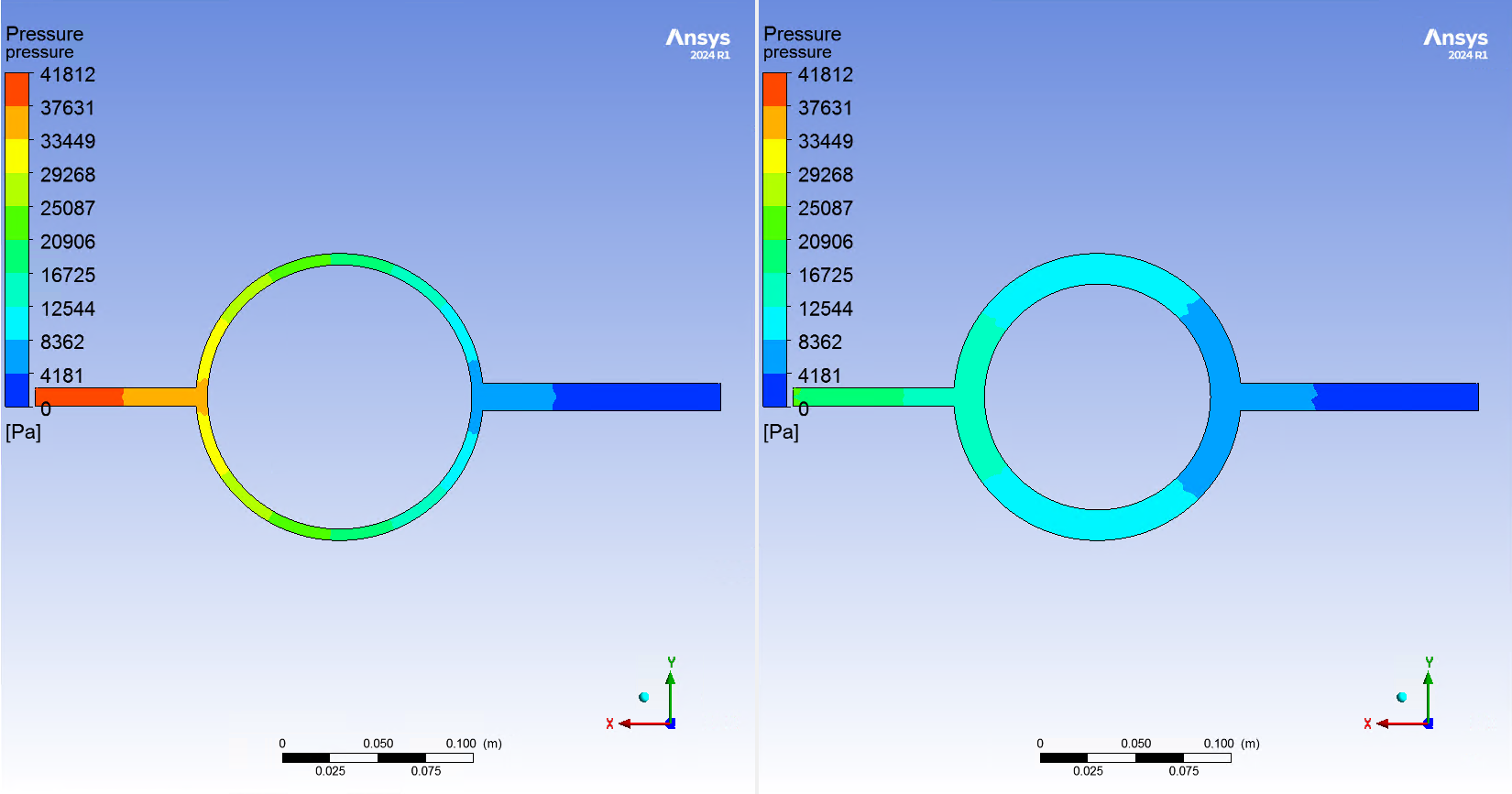

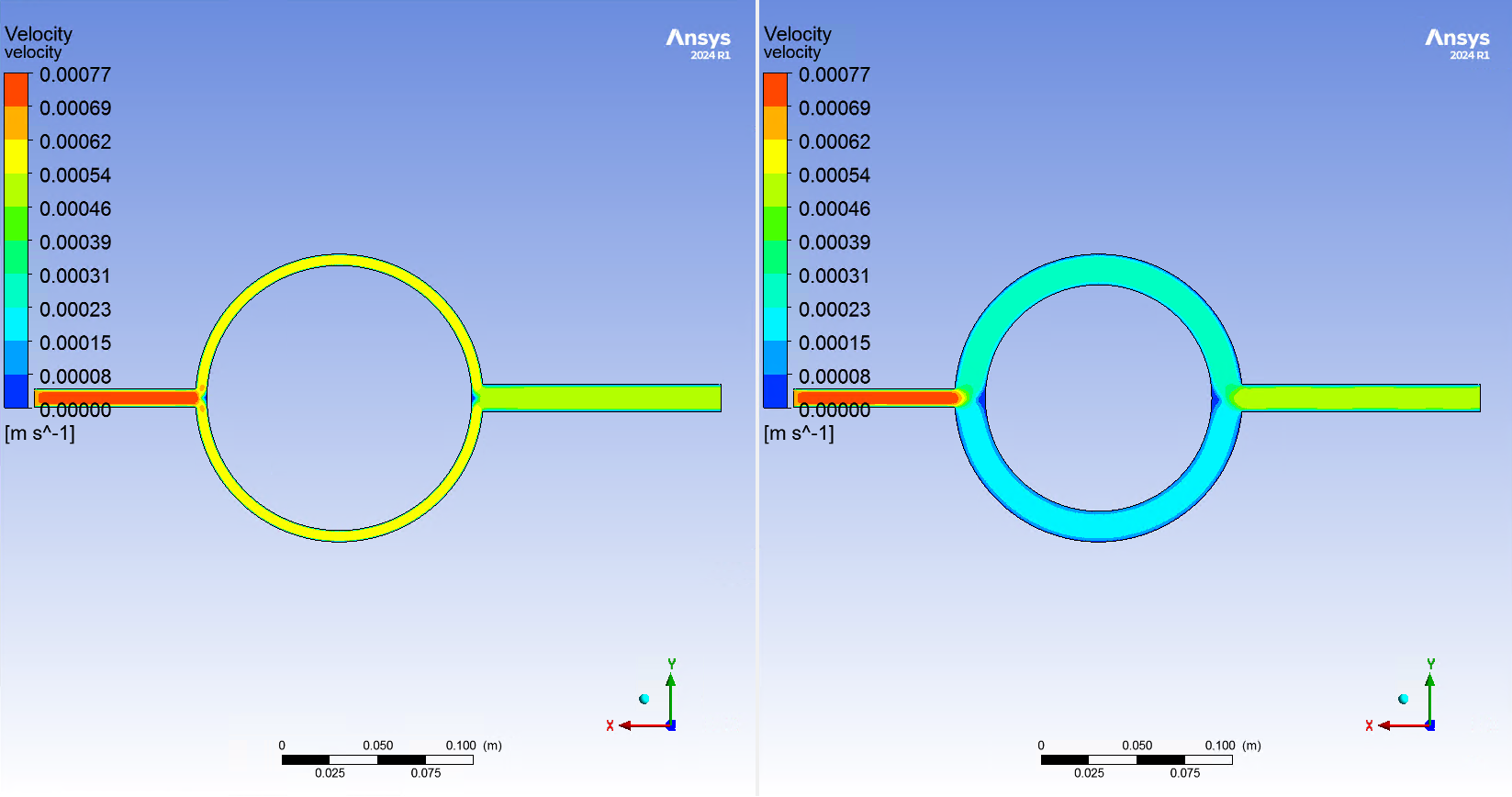

Some images about the velocity and inlet profiles:

Comparison between Case #1 (left) and Case #2 (right):

Comparison between Case #2 (left) and Case #3 (right):

Thank you for your interest and best regards.

-

May 21, 2024 at 10:23 am

Rob

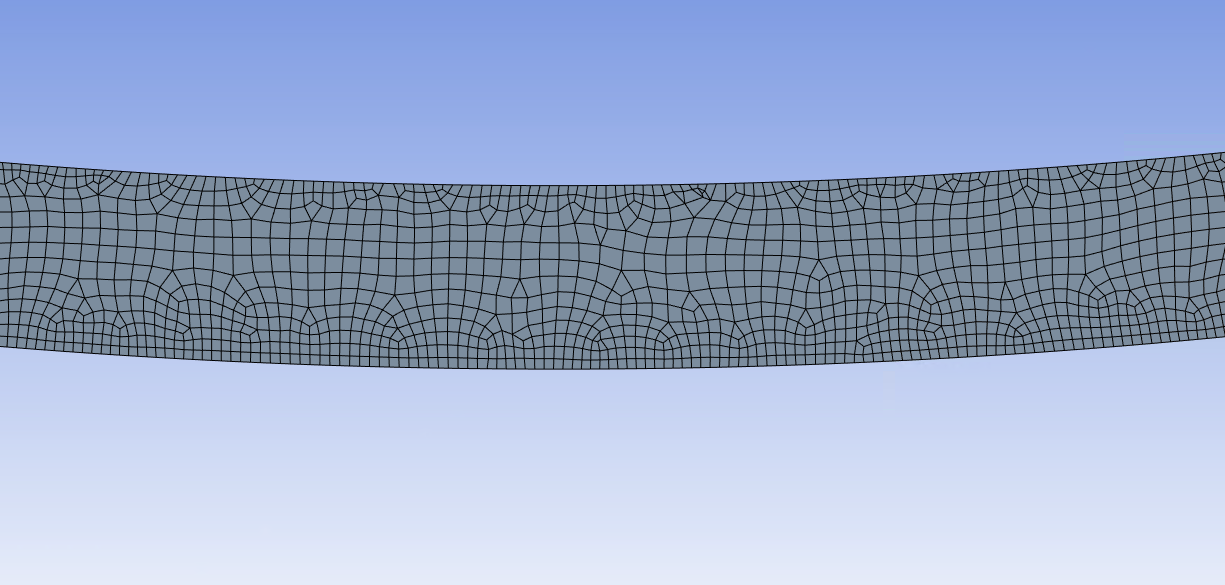

Forum ModeratorInlet pressure will increase with Case 1 - it's a smaller channel so that makes sense. Domain average is a bit more complicated as it's dependent on where the pressure drop occurs. I'd also question the asymmetry in Case 1, how many cells are there in the annular gap?

-

May 21, 2024 at 1:06 pm

Antonio Sola

SubscriberAnd what represents the pressure at the inlet? Why is bigger when the annular duct diameter is smaller?

I understand the domain average is more complecated because I don't have the same number of elements in all models and what you say, but the comparisons using the same scales show the pressure is always smaller (almost at all the points) when the annular duct increase its diameter...

In case 1 there are 13 cels in the annular gap..

Thank you!

-

May 21, 2024 at 1:10 pm

Rob

Forum ModeratorWhat causes a pressure loss in a system? Check your notes, and possibly look up Moody Charts and discharge coefficients.

You may want to review the mesh, it's fairly good but given the flow field you may want to look at growth rate.

-

May 21, 2024 at 1:32 pm

Antonio Sola

SubscriberOk! Thank you for your suggestions.

Could you please confirm me the pressure Fluent is measuring is the total manometric pressure, that means the sum of static pressure + dynamic pressure?

-

May 21, 2024 at 2:47 pm

Rob

Forum ModeratorIt's what you choose to check - "pressure" is static, but you also have other options. They're explained in the User's Guide, Chapter 42.

-

- The topic ‘Laminar flow and pressure measurements’ is closed to new replies.

- JACOBI Convergence Issue in ANSYS AQWA

- Is it able to solve turbomachinery using density-based solver in Fluent?

- Two-way FSI simulation

- Ensight Force_per_unit area_EV

- RIBBON WINDOW DISAPPEARED

- Fluent Meshing Error when .dsco not .stp

- Ansys Fluent for modelling Ocean Wave reactions to Wave Barriers

- Battery Pack cooling

- ISAT ABORT error

- UNASSIGNED INTERFACE ZONE DETECTED FOR INTERFACE…

-

4597

-

1495

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.