-

-

June 17, 2019 at 6:20 pm

-

June 23, 2019 at 12:18 pm

Mirghani

SubscriberHi

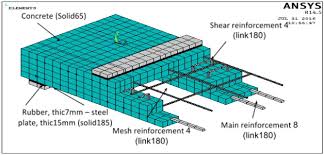

Did you include all commands for (SOLID65, LINK180 and the command for combining the LINK180 with SOLID65 concrete element)?? if not, then you need to include the following commands for concrete, steel and the command to combine SOLID65 & LINK180 in the pre-processor (Static structural branch in workbench tree) respectively

SOLID65 command under concrete geometry in workbench tree.

et,matid,solid65

keyopt,matid,3,2 !Suppress mass and applied loads, warning message and apply consistent Newton-Raphson load vector.

keyopt,matid,7,1 !Include stress relaxation

keyopt,matid,8,1 !Suppress warning message for totally crushed unreinforced element

MP,Ex,matid,22000

MP,Prxy,matid,0.18

MP,Dens,matid,2400e-9

TB,concr,matid

tbdata,1,0.15,0.2,3.1,28

LINK180 command under steel geometry in workbench tree.

ET,matid,LINK180

MPDATA,EX,matid,,2e5

MPDATA,PRXY,matid,,0.3

TB,BISO,matid,1,2

TBDATA,,355,2100,,,,

R,matid,71.252, ,0

COmbine SOLID65 to LINK180 under the static structural branch in workbench tree.

/PREP7

ESEL,S,ENAME,,65

ESEL,A,ENAME,,180

ALLSEL,BELOW,ELEM

CEINTF,0.00001,

ALLSEL,ALL

/SOLU

-

June 24, 2019 at 10:36 am

Dodo

Subscriberthank you for the reply,

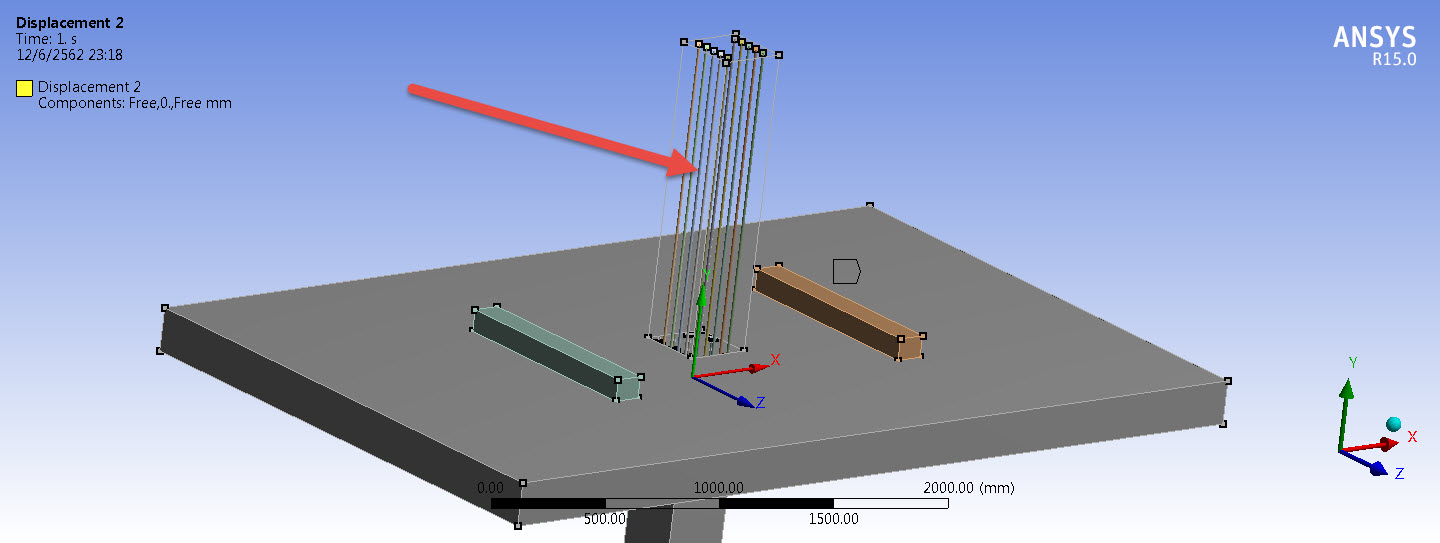

But Error occurs when using APDL combine SOLID65 to LINK180 in the model. after try to increase node about rebar(Link180) in concrete(Solid65) and use APDL contact, the model is work but use a long time to solve, so you have another way to fix this.

/PREP7

ESEL,S,NM_BEAM,,65

ESEL,A,NM_SLAB,,180

ALLSEL,BELOW,ELEM

CPINTF,ALL,0,0.00001

ALLSEL,ALL

/SOLU

-

June 25, 2019 at 1:58 pm

Mirghani

SubscriberHi

based on the snap you provided I can easily say that your mesh needs to be updated. the link180 and solid65 element nodes should be matching (see snap)

In general it's tricky to get SOLID65 element to converge with both cracking and crushing activated, the load (displacement controlled) should be applied at a very slow rate with a fine mesh. If the concrete cracks are not important in your analysis then you can try the newly developed Microplane model using SOLID185 with damage elasticity/plasticity or with CPT215 coupled damage

There are two ways to use the micro-plane model

The Elastic Micro-plane model with damage is supported by the element Solid185. A snippet example

ET,MATID,185 ! Define elements as SOLID185

MP,EX,MATID,29100 ! Define Elasticity Modulus

MP,NUXY,MATID,0.2 ! Define Poisson's ratio

TB,MPLANE,MATID,,6 ! Define the microplane model parameters

tbdata,1,0.75,0.75,0.208,6.109e-05,0.512,98 !k0,k1,k2,α_mic, β_mic, beta_mic

The Coupled Damage-plasticity Micro-plane model is supported by the element CPT215. This model was presented on the paper by Zreid and Kaliske (2014, 2016, 2018)

(Link to the 2018 paper: https://dl.acm.org/citation.cfm?id=3296167)

A snippet example

! Material Properties

ET,1,215 ! Define elements as CPT215 (Coupled damage plasticity) (Change Number 1 with Matid (material ID) if using workbench)

KEYO,1,18,2 ! Activate extra degrees of freedom

! Parameter values

E = 40300

nu = 0.2

dens = 2.4e-09

fuc = 36.5

fbc = 41.975

fut = 2.56

Rt = 1

D = 4e4

sigVc = -40

R = 2

c = 1500

m = 2.5

gamt0 = 0

gamc0 = 2e-6

betat = .4e4

betac = .25e4

! Define elastic properties of material

MP,EX,1,E ! Define Elasticity Modulus (enter a value for E)- (Change Number 1 with Matid (material ID) if using workbench)

MP,NUXY,1,nu ! Define Poisson's ratio

MP,DENS,1,dens ! Define material Density

! Define microplane model properties

TB,MPLA,1,,,DPC ! Define Drunker-Prager

TBDATA,1,fuc,fbc,fut,Rt,D,sigVc

TBDATA,7,R,gamt0,gamc0,betat,betac

TB,MPLA,1,,,NLOCAL

TBDATA,1,c,m -

June 26, 2019 at 4:30 pm

-

- The topic ‘How to contacts rebars (link180) with concrete (solid65) :(2)?’ is closed to new replies.

-

3712

-

1313

-

1163

-

1090

-

1014

© 2025 Copyright ANSYS, Inc. All rights reserved.