-

-

March 11, 2024 at 2:14 am

abdullahhassan

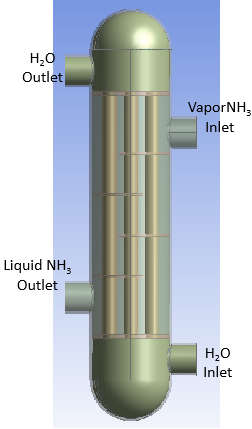

SubscriberHello All, I am doing a condensation simulation on multitube heat exchanger. You can check the simulation model below.

Water is running in seven tubes where as vapor ammonia enters into shell and should exit as a water ammonia. the system is -y (Downwards) gravity assisted.

After the simulation, what i found is that Ammonia liquid inside the domain is very less but at the outlet is very high. I have put the comparison in table below for easy understanding.

Properties

(Based on Mass Weighted Avg values)

Shell Domain

(NH3 Vapor --> Liquid)

Shell Inlet

Shell Domain

Shell Outlet

NH3 Vapor

1

0.99999451

0.99998504

NH3 Liquid

0

0.000005487

0.60698248

In my understanding, as the system is gravity assisted so the ammonia liquid is accumulating at the outlet of shell domain over time. but my question, how can i find the exact condensation amount in any particular time. or how can i say that by this mass flow, ammonia liquid is condensed and going out of the system?

MODEL is VOF implicit model.

-

March 11, 2024 at 10:30 am

Rob

Forum ModeratorI don't know what is in the table. Review how VOF works, have you resolved the flow sufficiently? What do the residuals and contours of phase look like? You may want to delete the tube side and just use a convection boundary to represent the water while you get the model working.

-

March 11, 2024 at 10:46 am

abdullahhassan

SubscriberThankyou for your reply.

Can you please elaborate it a little?

"You may want to delete the tube side and just use a convection boundary to represent the water while you get the model working".

-

March 11, 2024 at 11:00 am

abdullahhassan

SubscriberThe table shows the volume fraction of NH3 liquid and NH3 vapor inside the shell domain, shell inlet and shell outlet.

residuals are not yet converged but are each residual is oscillating below 1e-6.

Contours show nothing in terms of NH3 liquid, i think it because it value is near to negligible inside the domain.

Sorry as my reply breaks in two parts. -

March 11, 2024 at 11:49 am

Rob

Forum ModeratorIf the liquid fraction is too low to show why is the VOF model a good choice?

You currently have two distinct fluid domains, and that can make convergence tricky. If you remove the water domain, but set a boundary condition on the water surfaces to reflect the cooling you simplify the model and reduce the cell count.

-

March 11, 2024 at 11:25 pm

abdullahhassan

SubscriberThank you Rob.

I have studied this thing alot in many comments but i really can't find any way to do this.

Can you help me in directing towards a guide section. How can I remove one domain and set a boundary condition.

It will help me alot in solving this matter.

Thank you.

-

March 12, 2024 at 8:49 am

abdullahhassan

SubscriberHi.

QUOTE "You currently have two distinct fluid domains, and that can make convergence tricky. If you remove the water domain, but set a boundary condition on the water surfaces to reflect the cooling you simplify the model and reduce the cell count".

Is this mean, that i need to consider the tube fluid domain as a wall with some constant temperature to cool down the vapor striking on it.

in this way, i can re-mesh the geometry and simulate again?

-

March 12, 2024 at 10:08 am

Rob

Forum ModeratorOr just delete the cell zone in Fluent. Remeshing is the "proper" way to do it, but I'm a firm believer in the "principle of least effort". You can then set an external wall condition (I'd favour convection) to mimic the water side.

-

- The topic ‘Condensation in Shell and tube heat exchanger’ is closed to new replies.

-

4633

-

1535

-

1386

-

1225

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.