-

-

March 4, 2024 at 4:25 pm

Edzel Malongayon

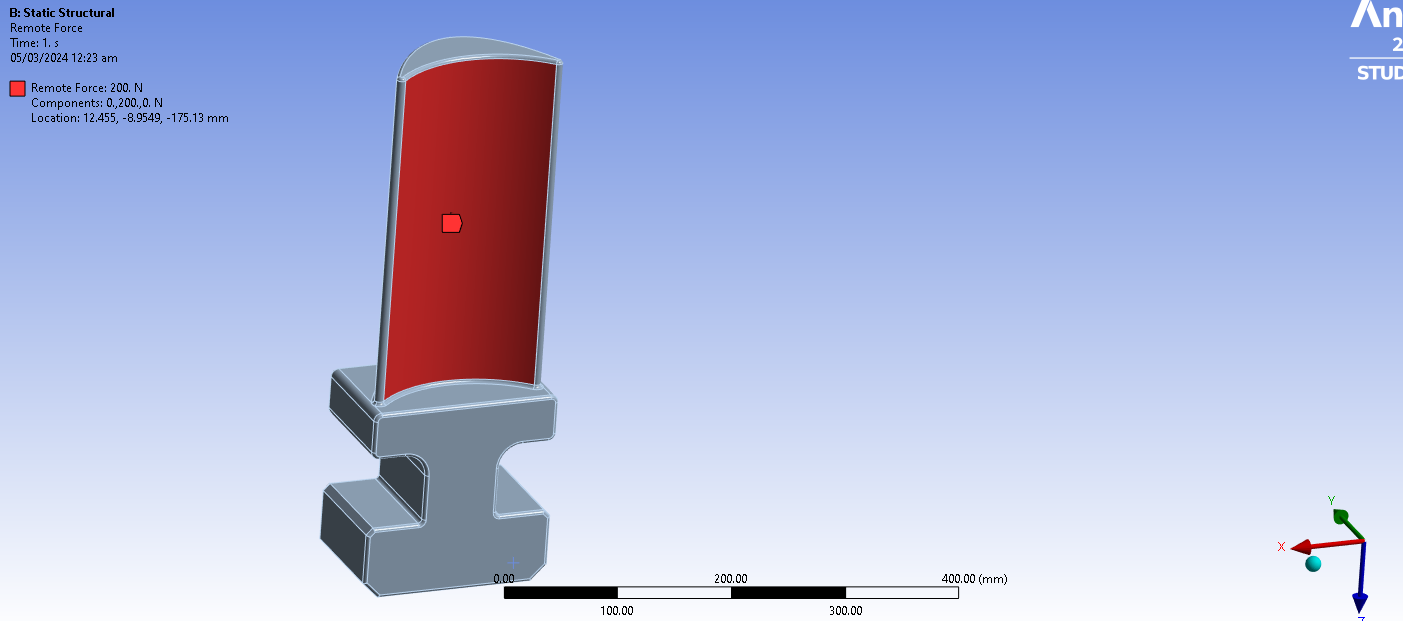

Subscriber So the picture above shows my structure, the thing is I want to know which support I should use and where should I apply it so that my structure could deform freely while still being properly supported. If possible, I would also like to subject the structure to a rotational velocity condition of 800 rad/s.

So the picture above shows my structure, the thing is I want to know which support I should use and where should I apply it so that my structure could deform freely while still being properly supported. If possible, I would also like to subject the structure to a rotational velocity condition of 800 rad/s. -

March 5, 2024 at 11:31 am

Ashish Khemka

Forum ModeratorHi,

For rotational velocity - define a revolute joint (body to ground) and then apply joint load. For the proper support. you can elaborate more on the application so that members can comment more.

Regards,

Ashish Khemka

-

March 24, 2024 at 11:24 am

Edzel Malongayon

SubscriberBasically a remote force of 760N would be applied to the turbine blade. Its just a static structural analysis but I am having trouble what support methods to use like 3 2 1 method since I cant use fixed support since the object is su jected to thermal expansion due to 750C tempwrature

-

March 24, 2024 at 5:53 pm

peteroznewman

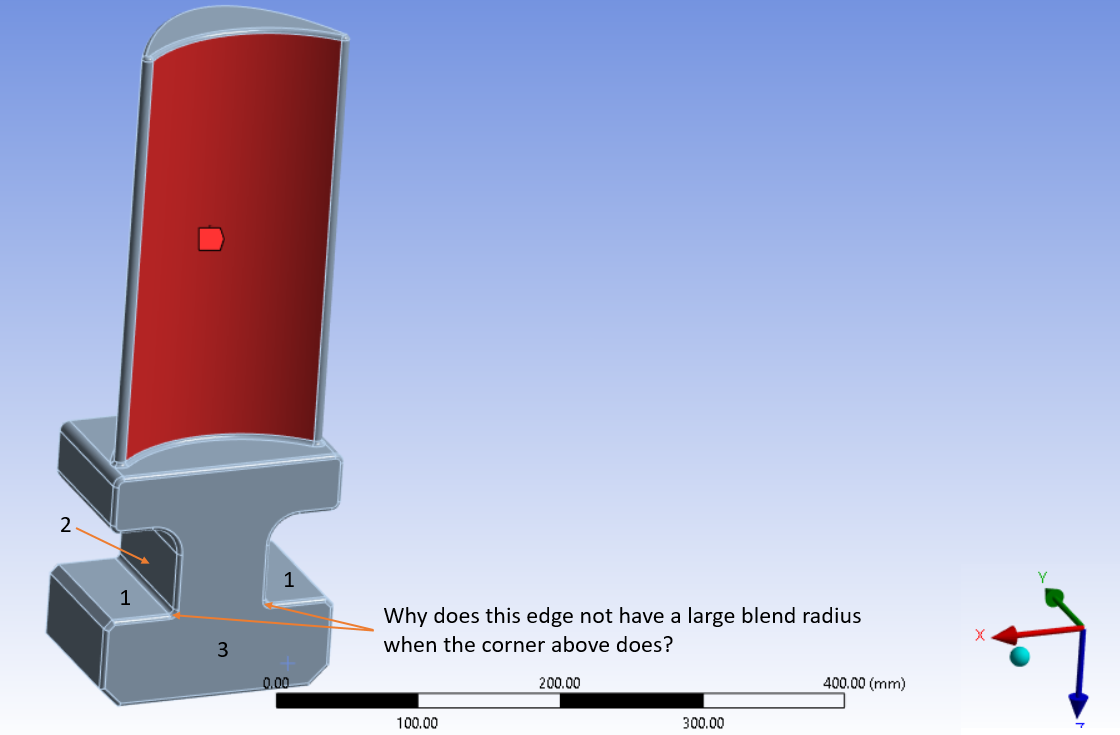

SubscriberThe faces numbered 1, 2, 3 identify faces you could use to create a “kinematic mount” that would allow for Free Expansion of the blade root under thermal expansion.

Assuming the two faces labelled 1 are parallel, use a compression only support to remove 3 DOF: Z, Rx and Ry. Apply a Remote Displacement, behavior = Deformable, on face 2 and remove 3 DOF: X, Y and Rz leaving the others Free. A different root design would have an angle between the two faces labelled 1 which would center the blade using the compression only support to remove 5 DOF and the Remote Displacement on face 3 would only need to set Y = 0.

A better simulation would model the matching features in the rotor and use frictional contact. Then the deformation in the rotor features would be included. The method of using just the blade and compression only support creates a perfectly rigid “rotor” with a sharp edge. Modeling the rotor allows you to put a blend on the edge of the features in the rotor.

I expect to see high stress on the two corners the arrows point to because of the constraint forces on faces 1.

I expect to see high stress on the two corners the arrows point to because of the constraint forces on faces 1.A remote displacement to apply a force to the face of the blade is not a good idea because more force will be applied near the center and less force will be applied far from the center if you are using a behavoir of Deformable. A better way to load the blade is with a pressure load. The best way to load the blade is to compute the pressure on the blade in a CFD simulation and import that load into Mechanical.

-

- The topic ‘Support boundry condition for turbine blade subjected to thermal expansion’ is closed to new replies.

-

4633

-

1540

-

1386

-

1225

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.