Ansys Learning Forum › Forums › Discuss Simulation › General Mechanical › Torsion Analysis of Circular Shaft Set-up › Reply To: Torsion Analysis of Circular Shaft Set-up

Hi Peter,

The material is made of 51CrV4 and is quenched and tempered. Also tube is part of a steering systems. I found the material properties and performed the analysis with large deflection in static structural. Thank you for your help. I have a small question about interpreting the results.

The maximum yield strength of the material is around 900MPa. When I apply a 45 Nm moment while doing the analysis, the system converges and the maximum stress is found to be like 920 MPa. When I increase the applied moment above 45 Nm, the analysis does not converge and gives an error after a point. In an article, it was said that one of the reasons why the analysis in Static Structural does not converge may be due to the forces not being able to balance each other. Also It was mentioning that if a large deformation occurs in the part, this deformation cannot be seen in the static structural, and therefore the analysis does not converge. So, while interpreting the results at which the system fails, can I say that the system is critical and may fail at points where the moment exceeds 45 Nm because system does not converge after that moment?

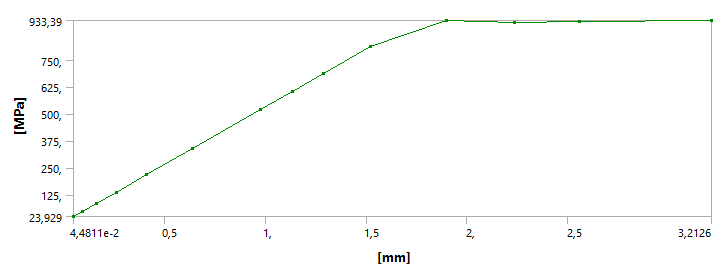

Also Is there any relation between deformation-stress graph and stress-strain diagram? I mean when I look at the deformation-stress graph below, can I say that the system is in the plastic region after the point where there is a sudden change in the line?