-

-

February 6, 2024 at 2:56 pm

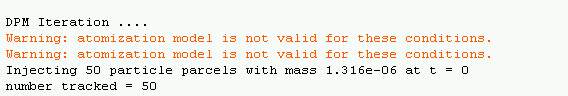

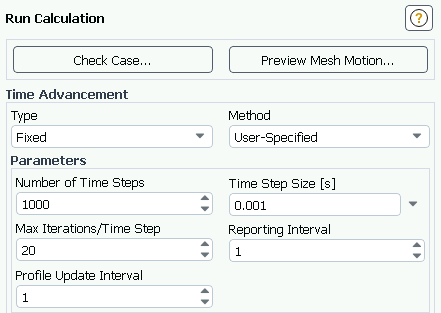

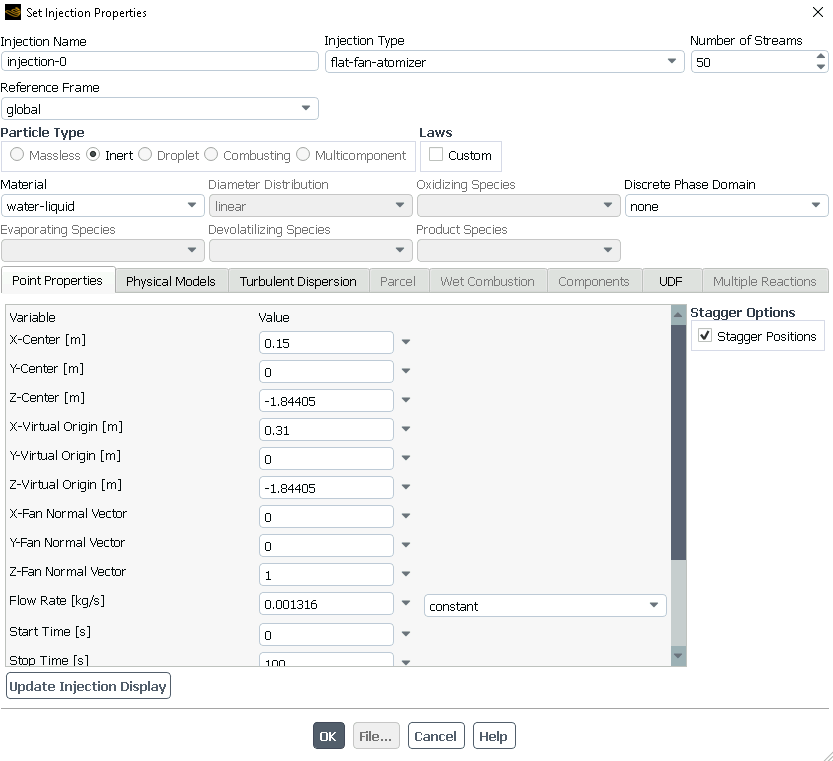

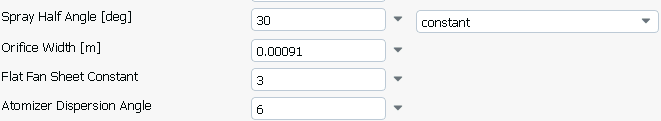

Greg Janes

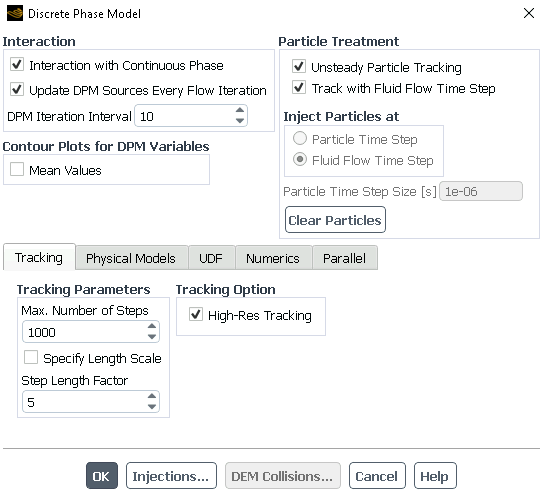

SubscriberI've been trying different settings to try to get this flat fan spray model to work, (Increasing and decreasing mass flow rate, fluid flow time step, and orifice width), yet nothing seems to work. I've been trying to find online how the model is calculated, reading the models paper etc., but nothing seems to provide a good outline to the conditions that need to be met in order for the flat fan model to work. I have attached some images of the settings that I have tried most recently. Ideally, the flow rate should be around 0.125 kg/s. Could you wonderful people help me get an understanding of how the flat fan model works and what parameters are essential to the success generation of this DPM simulation.

-

February 6, 2024 at 3:26 pm

Rob

Forum ModeratorLook at the centre & origin positions and then the normal flow vector.

-

February 6, 2024 at 3:32 pm

Greg Janes

Subscriberthanks for getting back to me Rob! Could you elaborate a little more on what you mean about my centre, origin, and normal vectors? The visual on my screen has the fan spray going in the correct direction on my screen, but does the centre and origin positions have to be a specific distance away from one another?

-

February 6, 2024 at 3:33 pm

-

February 6, 2024 at 3:33 pm

Greg Janes

Subscriber

-

-

February 6, 2024 at 3:55 pm

Rob

Forum ModeratorIf you look at the settings the fan normal is z, but the origin & centre positions vary in x.

-

February 6, 2024 at 4:00 pm

Greg Janes

SubscriberYea, thats what the diagram says I should do! I included the image of the flat fan spray, I thought that the normal vector is perpendicular to the spray direction. That is what is outlined in the diagram at least.

-

-

February 6, 2024 at 4:05 pm

Rob

Forum ModeratorOops, sorry, I misread the image - most of the injection models want the spray normal. What surface tension value is in the materials?

-

February 6, 2024 at 4:25 pm

Greg Janes

SubscriberNo worries at all, I appreciate you taking time to think about the issues. I am using ANSYS's standard liquid water model, but I didn't define any two phase interaction for this problem since its DPM and not VOF. Should I still be setting this us as a two-phase problem?

-

-

February 6, 2024 at 4:34 pm

Rob

Forum ModeratorNo, it's still single phase unless you switched anything else on - DPM isn't "multiphase" in the same way as the VOF/Mixture/Eulerian models. There should be a surface tension option in the DPM materials though. It looks like some of the fan break up maths is covered in the sheet break up section, https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v241/en/flu_th/flu_th_atomizer_pressure_swirl.html

-

February 6, 2024 at 5:43 pm

-

-

February 7, 2024 at 9:16 am

Rob

Forum ModeratorThe drag model shouldn't matter as that's more for what happens after the droplets are inside the domain. I'll check - I tend to use several fixed diameter injections over the injector models as I then know exactly what's going into the domain. It's then also easier to see what size (injection) goes where when post processing.

-

February 7, 2024 at 10:02 am

Rob

Forum ModeratorCan you increase flow rate by x100 or x1000 and see what happens? There are some hints here, https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v241/en/flu_th/flu_th_atomizer_plain_orifice.html which suggest the mass flow & speed are going to effect the droplet size distribution so there may be some built in warnings if the model(s) are out of the expected range.

-

February 7, 2024 at 2:07 pm

Greg Janes

SubscriberThe flow rate I usually use is 0.35 kg/s and it still gives me particle parcel mass warnings (the particle mass seems to scale with timestep). The case I was trying yesterday had a low mass flow rate because I thought that maybe my flow rate was to high. I am kinda lost on which parameters I should be changing to even see if it will work.

-

-

February 8, 2024 at 1:47 pm

Rob

Forum ModeratorOK, there are a couple of checks in the code, and they're flow & velocity related. The injected mass flow is kg/s which will also scale to the timestep and will sum to the total kg/s set in the panel.

I can't comment further (I've been talking to one of the Development team), but most of the maths is covered in the Theory Guide.

-

February 8, 2024 at 2:54 pm

Greg Janes

SubscriberThank you for you help Rob, I have read through the theory guide but will continue to try to continue making incremental changes in the model and see if anything works. I appreciate your guidance in this problem.

-

-

February 8, 2024 at 3:02 pm

Rob

Forum ModeratorYou should get the correct mass in the domain: the maths in question covers the droplet size.

-

- The topic ‘Flat Fan Atomization Model: Warning: atomization model is not valid…’ is closed to new replies.

-

4683

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.