-

-

March 22, 2019 at 6:22 pm

aCVP

SubscriberI am trying to simulate a moving heart with an implanted device using both fluent and mechanical as a fluid-structure interface simulation (i.e. passing imported displacements from mechanical to fluent). The mechanical simulation works as expected, but the fluent simulation fails (floating point exception and negative cell error).

Details are below. Any help would be appreciated - thanks!

-

March 24, 2019 at 1:47 pm

Raef.Kobeissi

SubscriberWhat's your initial time step? do you have any inflation layer in your mesh?

-

March 24, 2019 at 3:18 pm

aCVP

SubscriberMy initial time step is 0.001s (I have also tried 0.0001s and it still fails). I do have inflation layers - I used "last aspect ratio" with a first cell layer thickness of 0.2mm. The flow is laminar though, so I am not sure how necessary these inflation layers are...

Please note: The simulation ran flawlessly when it was just the ventricle without the device. However, this simulation has the implanted device, so I am pretty sure the negative cell volume error is occurring because of the presence of the device. I am not sure how to correct this.

EDIT: I removed the inflation and the error still came up.

I also found that creating a courser mesh allowed the simulation to run to completion. However, this is not what I want as the accuracy is considerably reduced. -

March 25, 2019 at 11:50 am

Rob

Forum ModeratorIf a coarse mesh works, have a look at the speed the surface moves at and check that against the cell size & time step of the finer mesh. It's possible you've got a small cell somewhere that's being twisted by the motion & too big a time step.

-

March 25, 2019 at 2:31 pm

aCVP

SubscriberAccording to my excel file, the maximum displacement is 0.995mm. As shown in the above posts, in mechanical I chose "ramped" for tabular loading. I was hoping this would apply the load over time at a slower rate.

It might be important to add that even though I chose "ramp" on my tabular loading, my load graph does not appear to be ramped as shown below.

For system coupling, my time step is 0.001s.

In Fluent, I added the following body sizing to the mesh for my fine mesh:

Element size: 1.0mm

Defeature Size: Default 2.9902e-002mm

Size Function: Curvature

Growth Rate: Default (1.2)

Curvature Normal Angle: Default (18.0)

Local Min Size: 1.0mm

How would you recommend I change this to avoid twisting cells?

Thanks again for all of the help!

-

March 27, 2019 at 4:53 pm

aCVP

SubscriberUpdate: I was able to fix the tabular loading in Mechanical so that the ramping looks correct. However, I am still struggling with the FSI simulation.

The errors range from the abovementioned negative cell error in Fluent to "excessive element distortion" for Mechanical. This is unusual because the Mechanical simulation runs fine by itself. I tried lowering the "under-relaxation" parameters in Fluent, but the problem still remains.

Of note: the error usually occurs about an hour into the simulation, which is a bit frustrating - is there any way to know that this error will occur before wasting this time?

I am positive the problem is with my fluent setup (either mesh or dynamic mesh settings)...especially because the material is "myocardium" (i.e. close to silicone).

Can adaptive meshing take care of this? What about cut-cell meshing?

Any advice would be appreciated - thanks!

-

April 1, 2019 at 6:43 pm

aCVP

SubscriberA Final Update: I was able to solve my issues by switching to an ANSYS Fluent UDF for nodal displacement. I avoided the negative cell volume error by having a smaller deformation per timestep. (This also made it easier to visualize where the negative cells were located).

It seemed like FSI wasn't the way to go for this, but the UDF saved the day.

Thanks again for all of the help and sorry for the trouble!

-

February 14, 2021 at 3:31 am

student90

SubscriberHello,nI am also trying to run a 3D 1-way FSI model in Fluent and after few time steps negative cell volume error shows up. the mesh is all tetrahedral and I am trying to apply remeshing on top of smoothing. I have been adjusting different parameters in smoothing and remeshing windows but still, it is not working despite having small time steps. nif I check the local cell option in remeshing, model becomes super slow and even when I do preview mesh motion, it takes forever to proceed just one timestep. while without local cell it goes through time steps very fast (and fails at some point). I have 110000 elements and it is not a really fine mesh. I am wondering why after checking local cell model becomes so slow? (one to four of cpu cores usage increase drastically and my whole cpu usage goes to 100% when I have local cell activated)nnthank youn -

February 14, 2021 at 7:44 pm

YasserSelima

SubscribernIf you have large displacement, only smoothing will not work as the mesh will have very high skewness and most probably you will end up by negative volume. nCan you show the parameters of remeshing? nAlso what do you consider small time step?n -

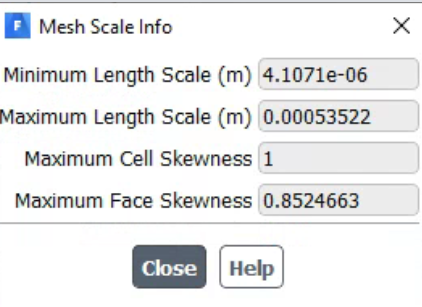

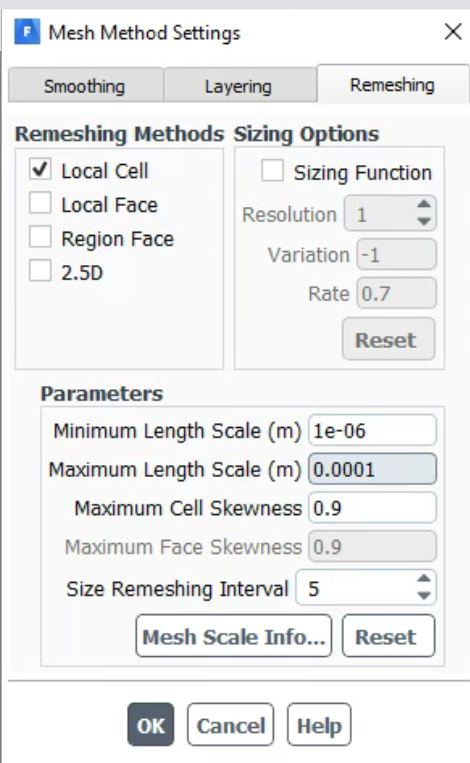

February 17, 2021 at 1:06 am

student90

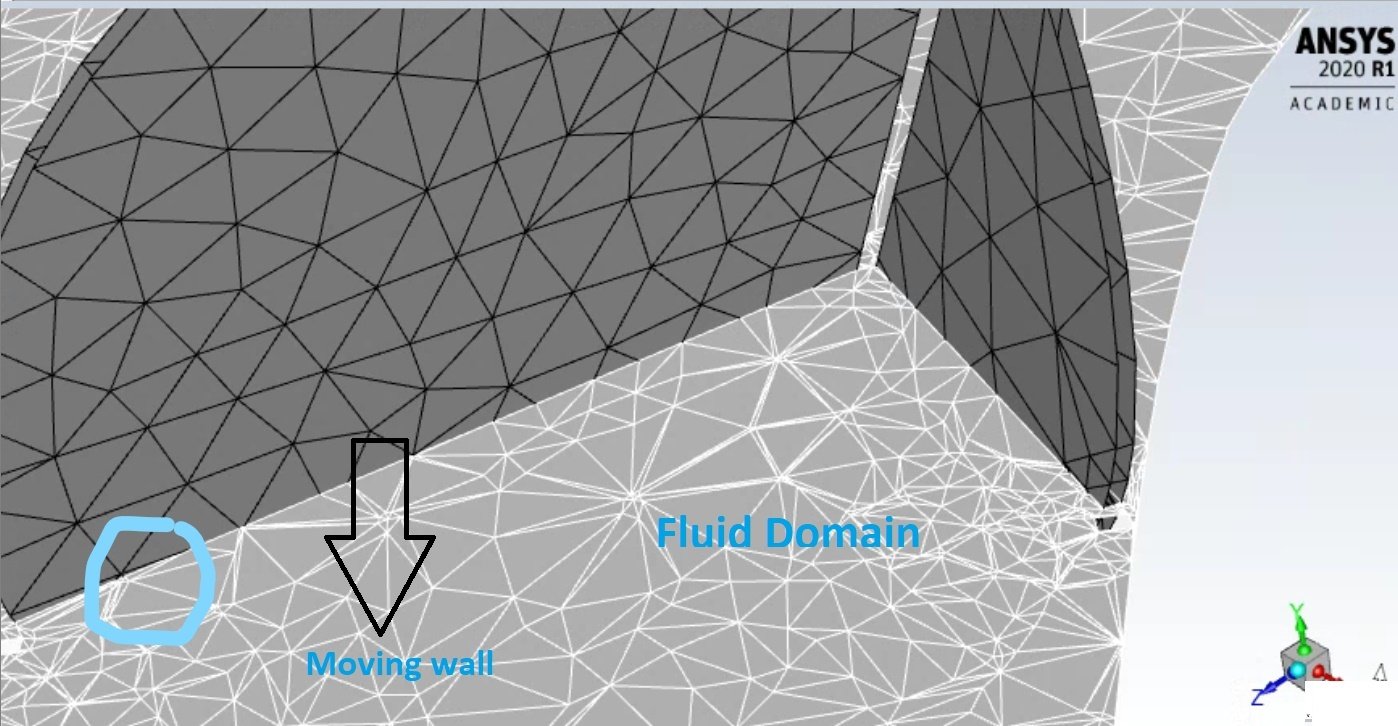

Subscribernthank you for your message. below is the setting I have considered for remeshing:nn nnwith the above setting, it took about 20 hours (100% CPU usage) to proceed 57 timesteps and Fluent crashed at some point. (it was remeshing)nwithout activating Local cell, preview mesh motion proceed up to 46 timesteps in few minutes and it fails with negative cell volume (I could not see any remeshing)nnMy question is why by activating Local Cell Fluent becomes incredibly slow and CPU usage goes up to 100%? (and without activating local cell it seems no remeshing happens)nnand by small timesteps, I mean leaflet displacement at each timestep is very small compared to the mesh element size. below is the fluid domain mesh and moving leaflet (moving wall):nn

nnwith the above setting, it took about 20 hours (100% CPU usage) to proceed 57 timesteps and Fluent crashed at some point. (it was remeshing)nwithout activating Local cell, preview mesh motion proceed up to 46 timesteps in few minutes and it fails with negative cell volume (I could not see any remeshing)nnMy question is why by activating Local Cell Fluent becomes incredibly slow and CPU usage goes up to 100%? (and without activating local cell it seems no remeshing happens)nnand by small timesteps, I mean leaflet displacement at each timestep is very small compared to the mesh element size. below is the fluid domain mesh and moving leaflet (moving wall):nn n

n

-

February 17, 2021 at 1:23 am

YasserSelima

SubscriberCan you press mesh scale info and post a photo of what you get?nAlso look here. Is this the original mesh or after smoothing?. n

n

-

February 17, 2021 at 2:09 am

-

February 17, 2021 at 3:44 am

YasserSelima

SubscriberWhat happens is that FLUENT mark all the mesh that does not meet the criteria and remesh them in 5 timesteps intervals.nMake the minimum length scale 0 and decrease the maximum to be in the same order of other mesh. and decrease the skweness ... I think this is what makes fluent mark most of your mesh to be remeshed. nIf you have fine mesh close to the wall, once the wall moves, they get a length scale below your minimum and get skewed .. and get marked for remesh. nHowever, remeshing should not be slow as you describe unless you run out of memory. Remeshing requires large memory , in addition to the simulation DATA that stays in memory, you might run out of memory ... And in this case, FLUENT uses the HDD drive as memory .. and this makes everything slow as you describe. Monitor the memory, if you go out of memory, consider running the simulation on a different computer if possible.n

-

- The topic ‘Dynamic Meshing Error (Negative Cell)’ is closed to new replies.

-

5094

-

1831

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.