-

-

December 20, 2018 at 10:58 am

jackhero

SubscriberI would like to ask a theoretical question regarding contact debonding for cohesive zone model (CZM) (Mode-II) based on Separation-distance based debonding. I carried out a simulation in static structural and have a confusion for which I request guidance from experts.

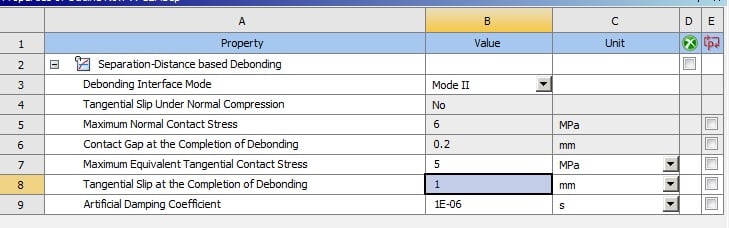

For the above mentioned Mode-II CZM,in Ansys workbench the required input values are as following,

1. "Maximum Equivalent Tangential Contact Stress (say in MPa)" From here-on mentioned as C3.

2. "Tangential Slip at the Completion of Debonding (say in mm)" From here-on mentioned as C4.

3. "Artificial Damping Coefficient" (say in sec) From here-on mentioned as C5.

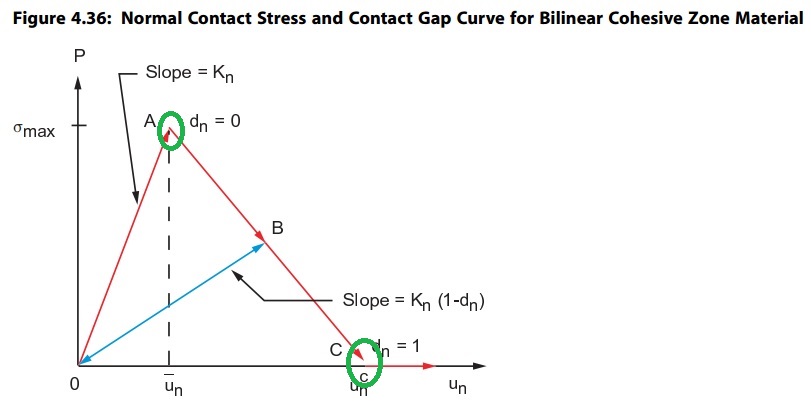

I checked the Ansys theoretical manual and from the manual the above mentioned input parameters (C3 and C4) are marked as green circles in the graph below. (for discussion let's call it Fig#1)

My questions are,

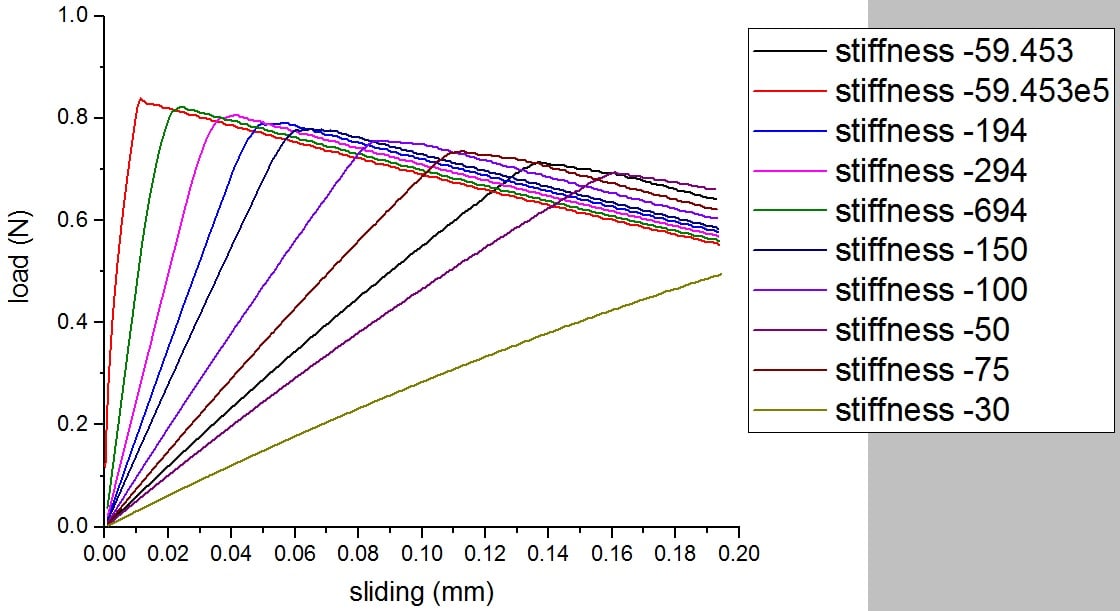

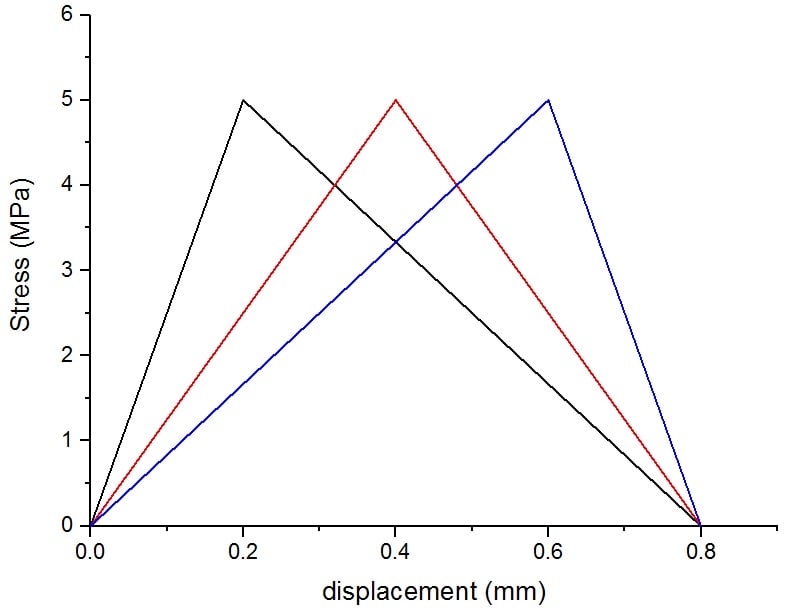

(a). If I input the above mentioned parameters for CZM (i.e. C3,C4,C5) then how does the Ansys solver differentiates between the following curves? The values for the following curves are imaginary which I made up to ask my confusion. In the curves below, all of the curves have same C3 and C4 values but the corresponding displacement or slip value of C3 are different. Noting that in Mode-II CZM we can only input the C3 and C4 and not the corresponding slip of C3. (for discussion let's call it Fig#2)

(b). If the answer to the previous question is because of slope (or initial gradient or stiffness), then could some one may clarify the following question. I input the following commands in my pull-out contact debonding model to modify the contact stiffness.

rmod,cid,3, -59.453

rmod,cid,11, -59.453

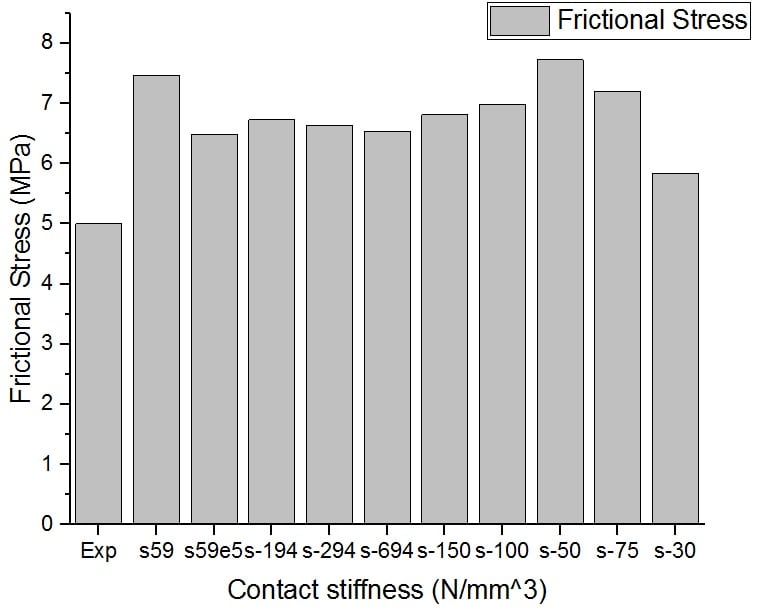

I ran the simulation with different values of stiffness but with the same CZM input values (C3,C4 and C5) and with same analysis settings and boundary conditions. I recorded the force reaction, slip and frictional stress, and plotted the results as shown below, (for discussion let's call it Fig#3 & Fig#4)

(b-i) why with the lower stiffness values, the load is also decreasing provided I did not change the CZM input values?

(b-ii) Shouldn't be with the same C3 and C4 values and with different stiffness I shall get the curve as shown in previous image above Fig#2?

(b-iii) Could someone please specify the issue and guide me how could I get the resultant values so that the hypothesis/theory mentioned above for Fig#2 could be verified/checked in Ansys simulation.

(b-iv) why do we use negative sign in defining the stiffness value via APDL command? I found these at here.

Thank you

-

December 20, 2018 at 1:27 pm

sk_cheah

SubscriberHi Jack,

Don't have a lot of experience here to advice theoretically but hopefully this is helpful...

(b-i) why with the lower stiffness values, the load is also decreasing provided I did not change the CZM input values?

Maybe worth doing a mesh sensitivity study. Contact stresses may be sensitive to mesh.

(b-iv) why do we use negative sign in defining the stiffness value via APDL command?

The negative value tells Ansys to interpret FKN as an absolute value and not based on the underlying element stiffness/dimensions. (PADT link)

Kind regards,

Jason -

December 27, 2018 at 9:18 am

Mirghani

SubscriberHi Jack

(b-i) why with the lower stiffness values, the load is also decreasing provided I did not change the CZM input values?

your Fig#2 represent the relation between the contact bond stress & Slip and you are asking about the force vs stiffness Fig#3

Regarding fig#3 the following equation is used by ansys for "Pure penalty" when CZM is used (Mode II - Pure Tangential force)

F (Tangential) = K (Tangential) * X (Sliding)

Where:

F: Contact Force

K: Contact Stiffness

X: Sliding Distance (Slip)

Based on the above equation if you are fixing the sliding distance (Tangential slip at the completion of debonding-C4) and decreasing the tangential stiffness (not directly but by decreasing the normal Stiffness FKN). then the bond/contact resisting force will absolutely decrease as shown in fig#3 and also this is common sense because if for example a lower stiffness adhesive is used as a glue between two materials then absolutely you will get a lower debonding force than if a higher stiffness adhesive is used giving that you assign them the same CZM input values (Bond stress & Slip).

Your fig#2 (Bond Stress vs Slip) is also valid as you are fixing the CZM material properties and changing the stiffness (Slope).

(b-iv) why do we use negative sign in defining the stiffness value via APDL command?

Already answered by SK_Cheah above.

The Question is why you are getting different bond stress values with different stiffness values (fig.#4) if you already said that you fixed the CZM material properties (Debonding Failure Criteria) i.e. the bond stress & the slip in the engineering data? maybe mesh refinement (parametric study) is needed as said by SK_Cheah.

-

January 29, 2019 at 9:29 am

Amin

SubscriberHi Jack,

for question (a): the input data for CZM are the maximum normal (or tangential) stress and the maximum gap (or slip). when you input the recommended values the gap (or slip) corresponding to maximum normal (or tangential) stress will be calculated by default, by considering the maximum gap (or slip) equal to six times the gap (or slip) when normal (or tangential) stress reach their maximum value.

Contact gap at the completion of debonding = 6 * the contact gap at the maximum normal stress

Tangential slip at the completion of debonding = 6 * the tangential slip at the maximum tangential stress

-

January 31, 2019 at 12:18 pm

jackhero

SubscriberDear Amin,

I used mode II debonding for which I need to input three parameters namely, maximum equivalent tangential stress, slip at debonding and damping coefficient. I manually entered the parameters from the experimental results for both stress and slip. I am not sure about the relations which you have mentioned in your post. as the experimental results were input directly and may not follow the relation mentioned above.

-

February 2, 2019 at 8:25 am

Amin

Subscriber

Hi Jackhero

My post is based on the following article. You can check it out: http://dl.lib.mrt.ac.lk/bitstream/handle/123/9502/SEC-11-100.pdf?sequence=1

-

May 9, 2023 at 1:57 pm

céleste marechal

SubscriberDear Jackhero,

I also try to simulate a pull-out so i am using debonding contact with the CZM law. I can not get the graph of the load in function of the sliding because of a problem of convergence and "The deformation is large compared to the model bounding box. ". I am simulating a debonding contact of an optical fiber inserted in matrix epoxy by putting a displacement at the end of the fiber. Do you know what I can do to complet my calculation ? I can send you picture if you need some.

Best regards

-

- The topic ‘Theoretical queries regarding debonding inputs in Ansys Workbench’ is closed to new replies.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Real Life Example of a non-symmetric eigenvalue problem

- Nonlinear load cases combinations

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

-

4167

-

1487

-

1363

-

1194

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.