-

-

November 21, 2023 at 10:49 am

Mark Boots

SubscriberHi,

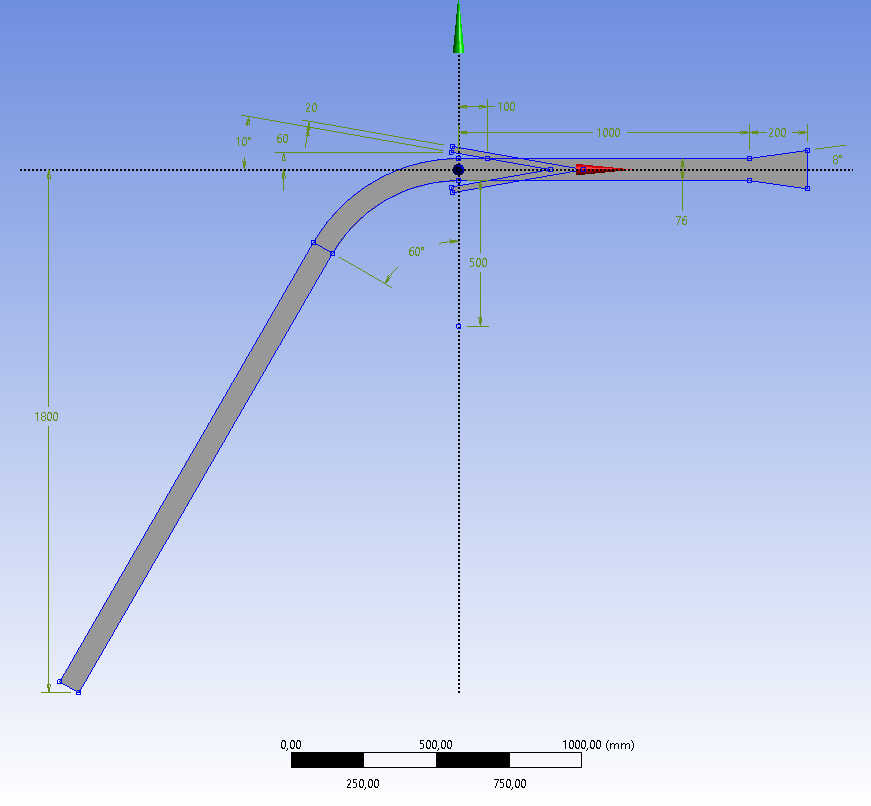

I'm currently working on a project where I have to design a dredge system (very simple by using the venturi effect to create a suction at the suction inlet by positioning 2 jets that accelerate the flow). I am changing the geometry and trying to discover what the influence of these changes is on the suction inlet velocity. One aspect that I have to investigate as well, is the use of different pumps that operate at the same power but have different amount of stages which results in high flowrate and lower head or higher head and lower flow rate.

In the picture below my geometry can be seen. I use an operating condition of 1 atm, at the suction inlet 0 Pa gauge pressure, at the outlet 0 Pa pressure and at the jets I convert 16 m^3/h to corresponding velocity. I want to use pump-curve data at the jet inlets.

Now my problem: I have trouble with understanding how I can impose the correct boundary conditions when I only know the inlet pressure and inlet velocity. Because using a pressure inlet results in too high flow rates and using Q=16 m^3/h as velocity inlet (v = Q / A / 3600), my pressures are too low.

Question: Which steps do I have to take in order impose a the jet a flow rate of 16m^3/h and a pressure of 11 bar?

Please can some help me? Thanks in advance!

-

November 21, 2023 at 11:43 am

Rob

Forum ModeratorIf the fluid isn't compressible you only get one of flow or pressure. Also note, a 2d system is nominally a 1m thick domain and in reality you may be looking at pipes so a direct comparison with experimental data may be difficult.

-

November 21, 2023 at 12:56 pm

Mark Boots

SubscriberYes, the fluid is incompressible. I do understand that comparing a 2D system to experimental data might not be precise, but I don't understand why well pump manufactures advertise with pumps with either a large head or a large flow. Because two different pumps can operate on the same flowrate, while one can produce a larger head then the other.

Maybe I need to rephrase my question then to "Is it possible to compare two pumps in Ansys with the same flow rate but with a different head?"

Do I have to change the outlet pressure or is only one solution possible (when connecting two different pumps with the same flow rate to the same jet-inlet)?

-

November 21, 2023 at 2:03 pm

Rob

Forum ModeratorIn reality the pump will spin/compress to push water through at a speed and with a certain pressure. If the losses in the pipework are low, the pump may deliver more flow, or the same flow for a lower speed/power draw.

In Fluent we tell the system we want some flow rate. The solver will then deliver that, and alters the inlet pressure until the desired flow is acheived. We can then look at the pump curve(s) to see what will deliver that pressure and flow, and if there are options which does it for a lower power draw.

-

November 21, 2023 at 2:09 pm

Mark Boots

SubscriberOf course, I know enough for now. Thanks a lot for you help!

-

- The topic ‘Only inlet velocity and pressure are known (venturi dregde)’ is closed to new replies.

-

4803

-

1582

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.