-

-

November 15, 2023 at 9:59 pm

mmia1

SubscriberHi

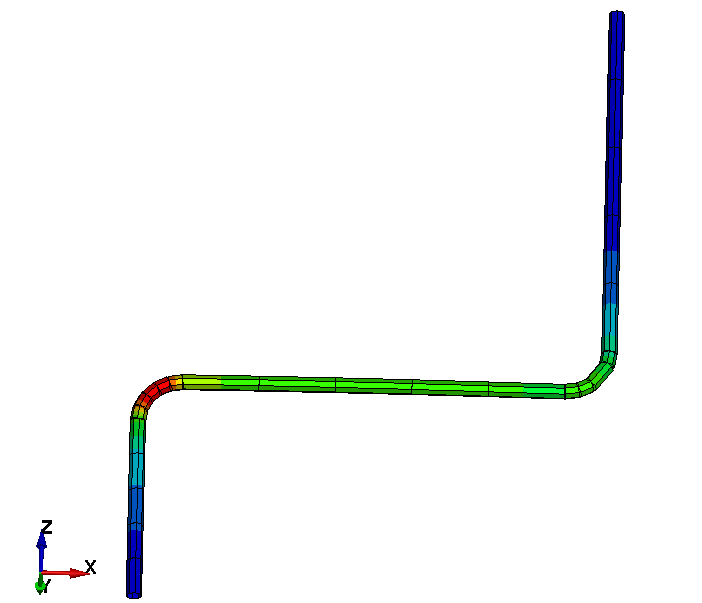

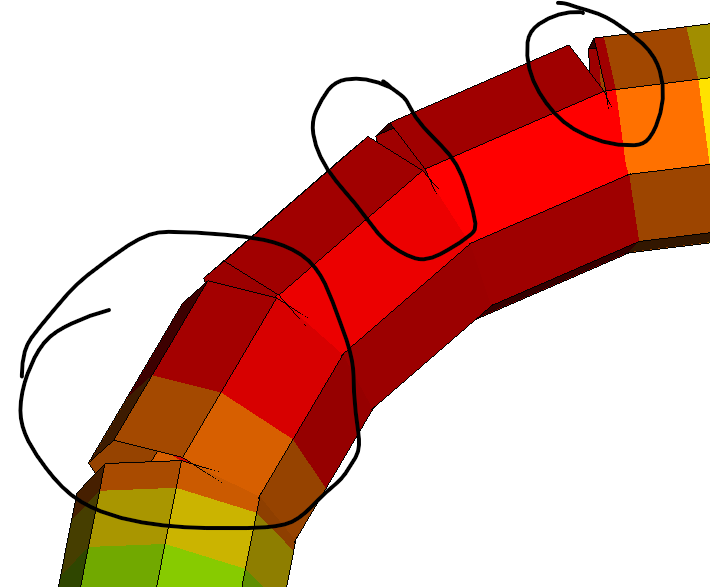

I have modeled pipes and elbow (picture below) using *ELEMENT_BEAM_ELBOW using LSDyna. My model converged but somehow the results are not making sense. The von misses stresses are way larger than what is expected. When I check the d3plot, I found that the elbow elements are separating badly (picture below). It happens for the second elbow as well. My *ELEMENT_BEAM_ELBOW definition is as below:

*ELEMENT_BEAM_ELBOW

1 1 1 4 3 (element ID PID N1 N2 N5 and the row below is midpoint N3)

2

2 1 4 8 3

6.............................................

*INTEGRATION_BEAM

1 0 0.0 9 2

0.161925 0.159125 0.0 0.0 0.0 0.0 0.0 0.0*SECTION_BEAM

1 14 1.0 -1 2 0.0 0.0 0

0.0 0.0 0.0Could anyone help me in this regard by giving me some suggestions what I am doing wrong? I did not get much help from manual and online. Thanks again.

-

November 17, 2023 at 5:20 pm

Jim Day

Ansys EmployeeI think the separation (and overlap) isn't real but just an artifact of looking at 1D beam elements in prism mode.

-

November 22, 2023 at 3:03 am

mmia1

SubscriberHi

Thank for the clarification. But still my model with *ELEMENT_BEAM_ELBOW using LSDyna gave me high von misses stresses compared to expected results (about 10 times higher). I followed the manual to model elbow and straight pipes. However, still no improvement. Details of the model and section and integration beam info can be found in my previous post of November 15, 2023, at 9:59 pm in this thread. Could anyone suggest me what I might do wrong? My material model is as below if anyone is interested.

*MAT_PLASTIC_KINEMATIC

$# mid ro e pr sigy etan beta

1 7.900E+03 2.070E+11 0.300000 2.07E+08 2.00E+09 0.000000

$# src srp fs vp

0.000 0.000 0.000 0.000(UNITS: N,m,s)

In another note, if I used regular beam elements (Elform =1) for both straight pipes and elbow, I got the expected results although I am not sure if is it okay to use regular beam elements (Elform =1) to model curved pipe instead of available *ELEMENT_BEAM_ELBOW element in LSDyna.

I would really appreciate if anyone can help me. Some of my colleagues said that regular beam elements (ELFORM=1) has some drawbacks in modeling elbow that’s why LSDyna introduced elbow elements, although they could not provide me any proof of that. Please help me in this regard. Thanks again.

-

November 22, 2023 at 5:43 pm

Jim Day

Ansys EmployeeFirstly, it's important to note that the ELBOW option of *ELEMENT_BEAM is earmarked as "beta" in the latest User's Manual. Secondly, if you go to dynalook.com and search on "elbow", the first hit will be a downloadable paper on the LS-DYNA elbow element. There are deformation modes included in the elbow element that are not considered in a straight, beam element like beam formulation 1. To some extent, those modes will affect the stresses.

-

- The topic ‘Need some help in *ELEMENT_BEAM_ELBOW’ is closed to new replies.

-

4833

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.