-

-

September 18, 2023 at 4:51 am

Jacob Ellis

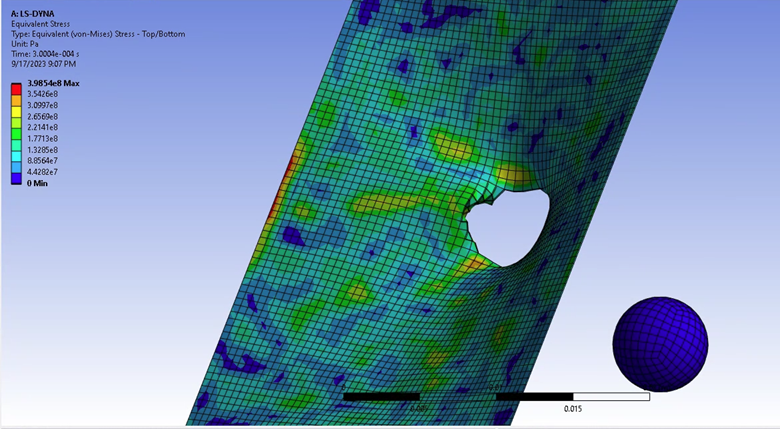

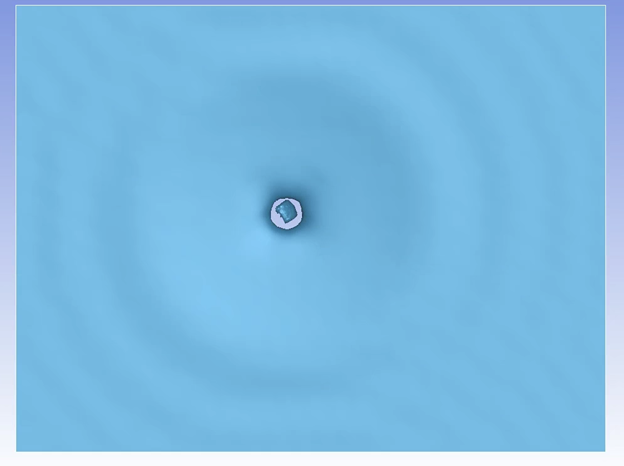

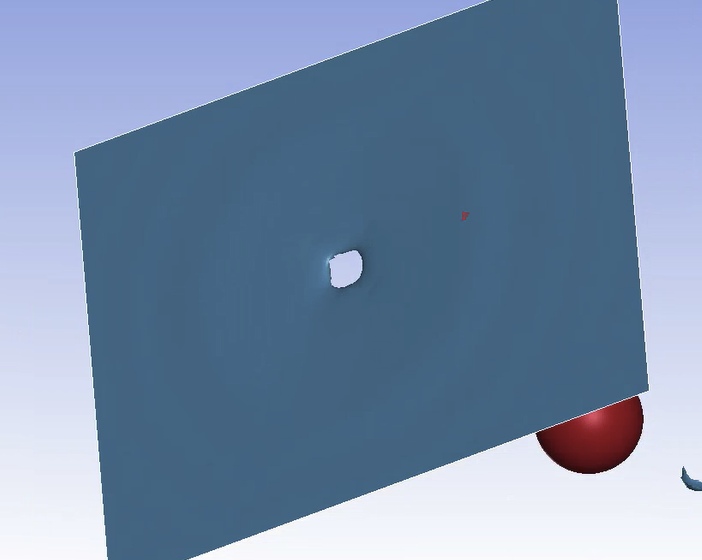

SubscriberI have a simple ball impacting a plate (with some added erosion to simulate a perforation). At a medium sized mesh I get expected results

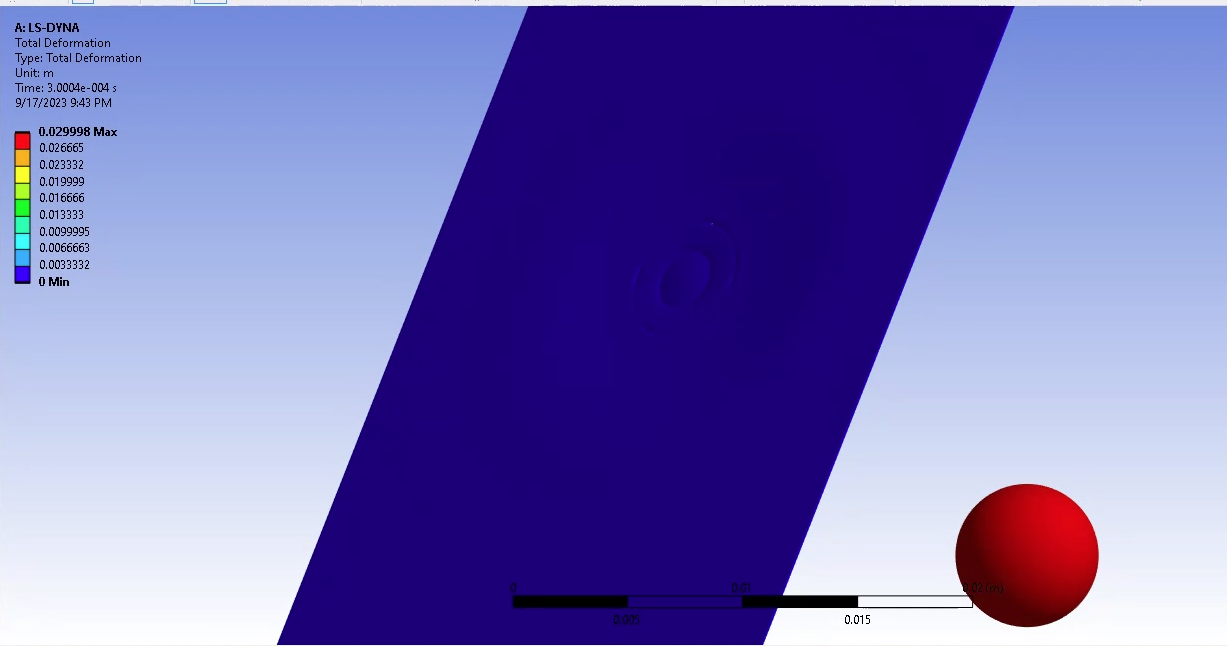

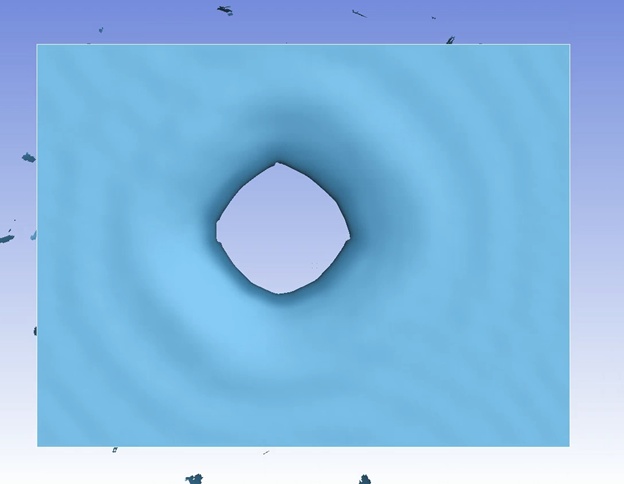

For the much finer mesh (below; mesh hidden since it is too fine). The ball seems to dimple the surface but then just ghosts right through the plate. Nothing was changed in the problem setup except for mesh size.

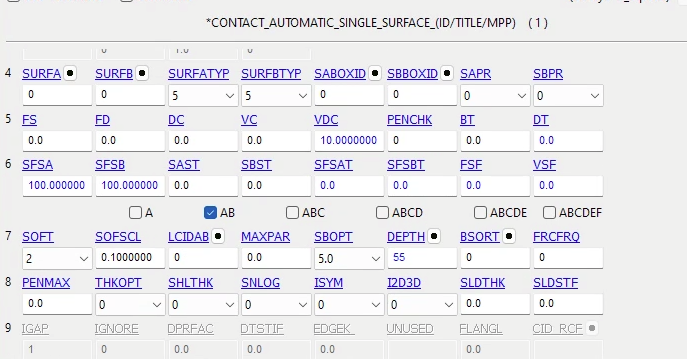

I am using AUTOMATIC_SINGLE_SURFACE with SOFT = 1 but this happened with SOFT = 2, also. Presumably this is something to do with the contact stiffness, since all formulations SOFT=0,1,2 have contact stiffness dependent on either the mesh size or the timestep (via, in part, the mesh size). I would have thought this would be handled more robustly for such a simple problem then have to manually tweak contact scale factors...

Perhaps there is an atlernative contact scheme that is more robust? If not, how do I know how much contact stiffness to add to get the same results as the coarse mesh. It is very counter intuitive that a coarse mesh produces better results in this case.

-

September 18, 2023 at 6:21 pm

Jim Day

Ansys EmployeeStiffening the contact is one way of approaching this problem. You could also try setting the contact THICKNESS to a value larger than the shell thickness. Use the variable SAST or SBST on Card 3 of *CONTACT_.... to set the contact thickness. A larger contact thickness will permit a larger penetration without giving up and releasing the penetrating node(s).-

September 18, 2023 at 6:26 pm

Jacob Ellis

SubscriberHi Jim,

Thanks for the suggestion. I switched to Mortar contact and it fixed the issue. Mortar seems to be really robust (though expensive). Even in Explicit. Is that the future of contact technology? Anything I should be worried about?

-

-

September 18, 2023 at 6:50 pm

Jim Day

Ansys EmployeeYes, Mortar contact is robust, but remains very expensive for explicit. I think it's speculative to say whether it will ever be practical for extensive use in explicit. Other contact types are faster and generally robust in explicit. -

September 18, 2023 at 6:54 pm

Jim Day

Ansys EmployeeI feel certain non-MORTAR contact input can be tweaked to give satisfactory results. Please give an update regarding your trial of non-MORTAR contact with increased contact thickness. And if you don't mind, please report run times for MORTAR and non-MORTAR contacts (same machine, same number of cores). -

September 18, 2023 at 10:50 pm

Ushnish Basu

Ansys EmployeeYou can also try SBOPT=5, DEPTH=55 with SOFT=2, in case you aren't already

-

September 19, 2023 at 6:35 pm

Jacob Ellis

SubscriberJim and Ushnish,

Thanks for your suggestions. SBOPT=5, DEPTH=55 with SOFT=2 had the same results. I have been trying to tweak the contact thickness and stiffness with no luck.

Do I need to tweak both SFSA and SFSB if it's *AUTOMATIC_SINGLE_SURFACE or just SFSB? Same question for SAST and SBST.

What range of values for SFSA/SFSB should I try first? And what percent of the shell thickness should I increase the contact thickness. I don't have a good feeling for what is reasonable and nothing I try seems to be working.

-

September 19, 2023 at 7:17 pm

Jim Day

Ansys EmployeeFor single surface contact, you can focus on "Surface A" parameters, SFSA, SAST. For this application though, I would suggest using *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE so the SURFA and SURFB are distinct and rcforc data via *DATABASE_RCFORC data is produced without need for a force transducer. -

September 19, 2023 at 7:18 pm

Jim Day

Ansys EmployeeYou're not invoking mass scaling on *CONTROL_TIMESTEP, correct? -

September 19, 2023 at 7:19 pm

Jim Day

Ansys EmployeeFor SOFT=2 only,the variables FNLSCL and DNLSCL allow for a nonlinear contact stiffness; see the Remarks on Opt. Card D of *CONTACT.

There are different forms for this type of scaling, but the first form goes like this …

Scaling factor on stiffness = FNLSCL * sqrt(penetration/DNLSCL)

so DNLSCL is the penetration at which the nonlinear scaling of stiffness begins.

I might suggest FNLSCL=10 and DNLSCL=0.1*shell thickness.

-

September 19, 2023 at 7:27 pm

Jacob Ellis

SubscriberJim,

I am not using mass scaling. I was able to finally get contact (without using MORTAR) by setting SFSA and SFSB to 100. Was this too heavy handed of an approach? That is, how do I know when the stiffness is too high. It "looks good" to me.

I am now running a timing comparison with MORTAR as you requested and will share when done.

-

September 19, 2023 at 7:27 pm

Jim Day

Ansys EmployeeIf adjusting contact STIFFNESS as described above, you can leave contact THICKNESS as default. -

September 19, 2023 at 7:35 pm

Ushnish Basu

Ansys EmployeeCouple of other things to try out along with SURFACE_TO_SURFACE contact as Jim suggested -

- Set BSORT=1 on Card A (or BCKT for MPP without SOFT=2)

- Reduce TSSFAC in CONTROL_TIMESTEP

-

September 19, 2023 at 7:40 pm

Jim Day

Ansys EmployeeScaling contact thickness by 100 seems heavy handed to me. Generally, you want the smallest contact stiffness that gives reasonable contact behavior (no excessive penetration and no pass-through). Overly stiff contact will often create an unstable solution, or if element erosion is allowed, premature erosion of elements and an unrealistic failure pattern. Looks like you have a nearly perfect circular hole in the target not much bigger than the sphere, which may be an artifact of overly stiff contact. Compare contact force time histories (via rcforc data) when comparing MORTAR to non-MORTAR. If you write that rcforc data at high resolution so as to get smooth curves, you can integrate the force vs. time curves to get impulse, that is, change in momentum of the sphere. -

September 20, 2023 at 3:49 pm

Jacob Ellis

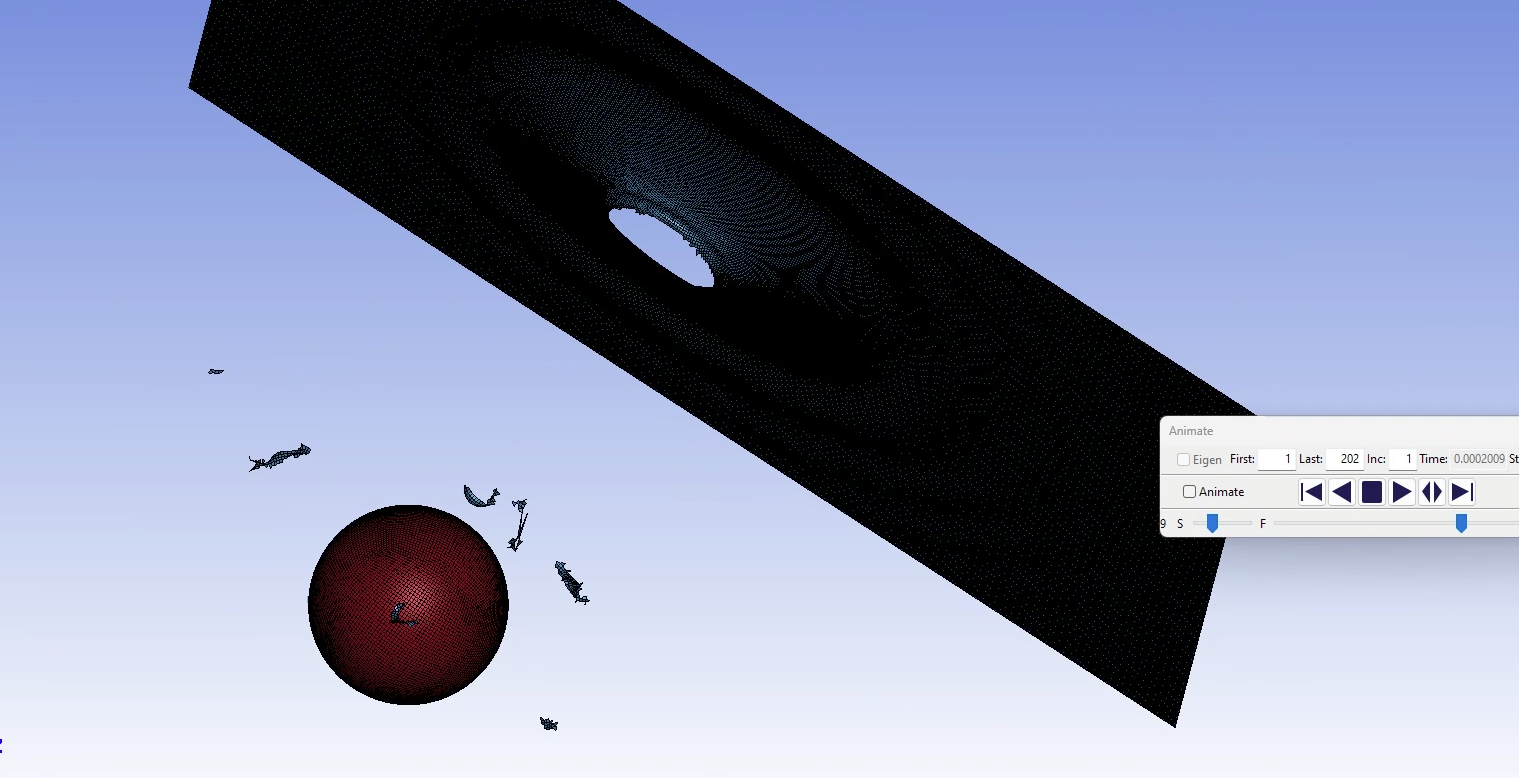

SubscriberSo, BSORT=1 showed a little bit of erosion. That seemed promising so I decreased the contact stiffness from 100x to 5x. The Mortar results still look way better (see below). The hole in the non-mortar version is small... smaller than the impacting sphere. I can integrate to get the impulse but nonetheless I want to get a reasonable size hole.

Non-MORTAR, SOFT=2, SBOPT=5, DEPTH=55, BSORT=1, Contact Stiffness Scaled 5x

MORTAR

-

September 20, 2023 at 4:12 pm

Jim Day

Ansys EmployeeYou've tried 5x and 100x the default contact stiffness. That's a pretty broad range. Try an intermediate value, e.g, 20x. Or, as I suggested earlier, invoke the variables FNLSCL and DNLSCL. -

September 20, 2023 at 6:09 pm

-

September 20, 2023 at 6:26 pm

Jim Day

Ansys EmployeeI don't have enough experience with MORTAR in explicit to say whether you can always count on perfect behavior in one shot, although that was the case for this particular model. I'd be surprised if that were the case.

-

- The topic ‘Finer mesh allows material to penetrate through’ is closed to new replies.

-

4618

-

1530

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.