-

-

August 31, 2023 at 5:21 pm

Tianyuan Wang

SubscriberDear all:

I would like build a coaxial double buoy in AQWA workbench, but I am a little confused about the lid method in AQWA.

% ========================

Q1:

In workbench, does the structural surface of the floating body on the SWL need to be preserved? I am not sure if the structural surfaces on the SWL are involved in the calculations.

This essentially relates to the principle of the internal lid method. If I turn on the internal lid method, does AQWA generate additional lid elements that are duplicated with the structural surface meshes on the SWL.

% ========================

Q2:

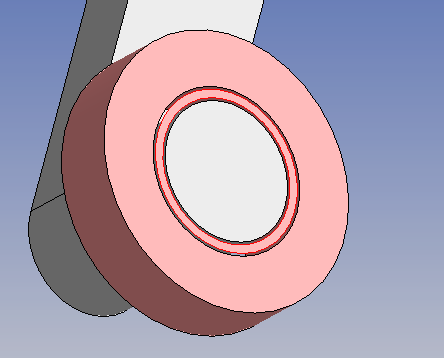

For a torus with a moon pool, assume that the structural surface on the SWL is deleted in the DM, does the internal lid method just generate the internal lid of the toroidal surface, or generate the lid including the toroidal surface and moon pool?

% ========================

Q3:

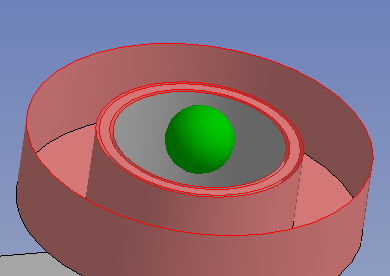

As for a coaxial double buoy, how could I generate a external lid of the narrow gap between inner and outer bodies?

(1) Which type is right?

A. a lid attached to inner body

B. a lid attached to outer body

C. a separate lid (2) Is there a clearance required between the lid and the other body?

(2) Is there a clearance required between the lid and the other body?(3) I found AQWA USER MANUAL highlights that lid normal should be pointing up (away from the fluid). Do all the lids have to meet this requirement? And this operation needs to be done in DM?

Looking forwards to hearing from you

Best regards,

Tianyuan?

-

September 1, 2023 at 8:55 am

Mike Pettit

Ansys EmployeeHello Tianyuan,

To answer your questions:

1. Generally, it does not hurt to include the structural surface on the SWL.

If you are only running a Hydrodynamic Diffraction calculation, it does not make any difference whether the structural surface on SWL is included or not - Aqwa will consider it as non-diffracting, and ignore it for the radiation-diffraction calculation. The same can be said for any other parts of a vessel above the mean waterline. However, if you are also going to run a Hydrodynamic Response stability analysis or time domain analysis (without slow drift), then you should include the structural surface. For these analysis types, Aqwa will calculate the hydrostatic pressure over the instantaneous wetted surface, so it is more accurate to include all of the structural surfaces in this case.

The existence (or not) of the structural surface on the SWL does not affect the internal lid. Once Aqwa decides that the structural surface is non-diffracting, it does not matter if the internal lid elements are overlapping.

2. The automatic internal lid method will create lid elements inside the toroidal surface only. The moon pool will not be covered.

3. For the external lid surface, either A or B is right. You should have a small clearance between the structural surfaces and the external lid surface - any clearance is fine, as long as they are not touching (i.e. not sharing nodes in the mesh). The Aqwa Workbench editor will automatically correct the lid normal if necessary, so you don't need to worry about it. (Generally, you need to use a Surface Flip operation in DM if you do need to change the surface normals for any other reason).

I hope this helps!

Mike

-

September 1, 2023 at 12:50 pm

Tianyuan Wang

Subscriber

-

-

September 1, 2023 at 4:56 pm

Mike Pettit

Ansys EmployeeHi Tianyuan,

You can specify the structural surface on the SWL as an internal lid, but you should modify the geometry so that there is a gap between the lid surface and the other structural surfaces (similar to the external lid).

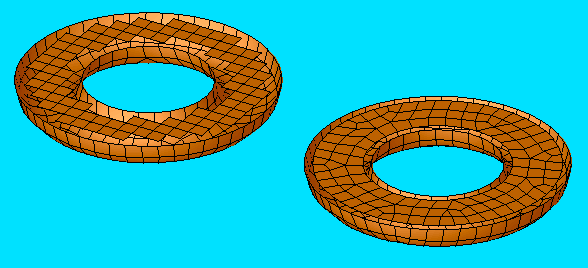

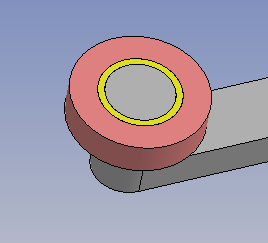

This is not exactly equivalent to using the 'Generate Internal Lid' option - the latter roughly fits square elements into the cut waterplane area inside the buoy, while the former will use the elements created by the Mesh. Here is an example of automatic (left) vs manually-defined (right) internal lids (visualised using AqwaGS):

You should not use an internal lid over the moon pool, as this will overdamp the water surface - it will remove all vertical wave motion from inside the buoy, which is not realistic. If you need to, you should rather create an external lid, which will allow you to tune the damping frequency (via the Gap value) and amount (Damping Factor value).

Cheers, Mike

-

September 8, 2023 at 5:18 am

Tianyuan Wang

SubscriberDear Mike:

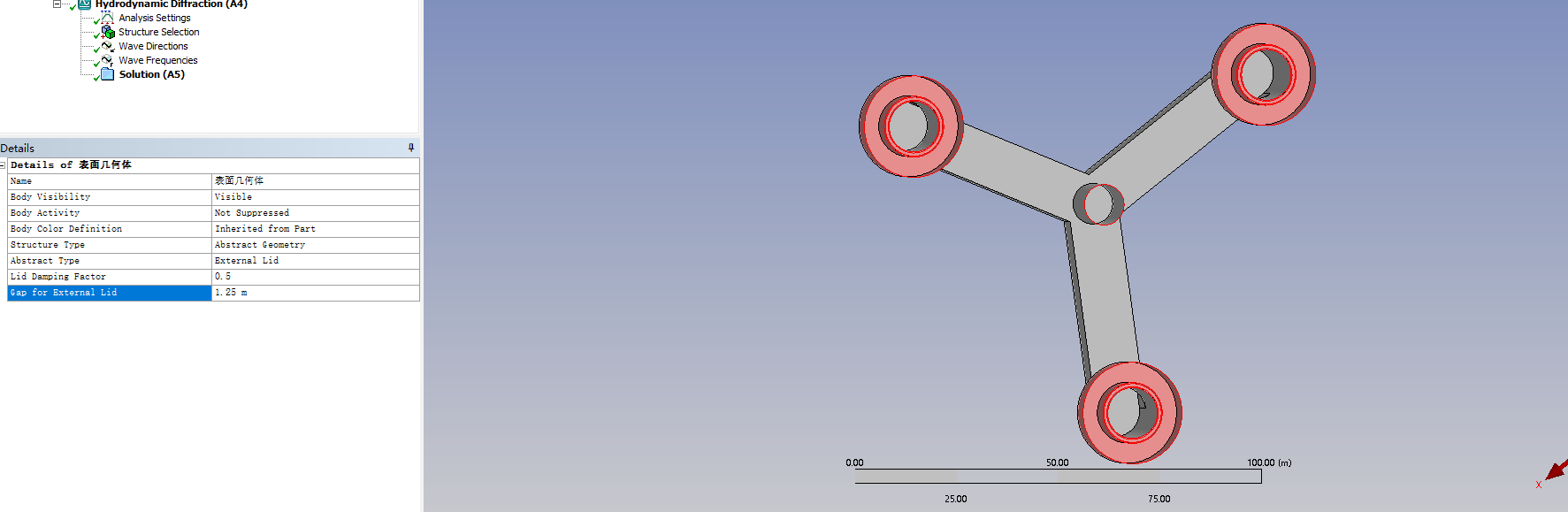

I recently conduct the simulation in AQWA-Workbench as you suggested. The external lid established in DM has a inner radius of 6.5 and a outer radius of 7.25. The actual gap between inner and outer bodies is 6.25-7.5, thus the Gap for External Lid is set to 1.25 m

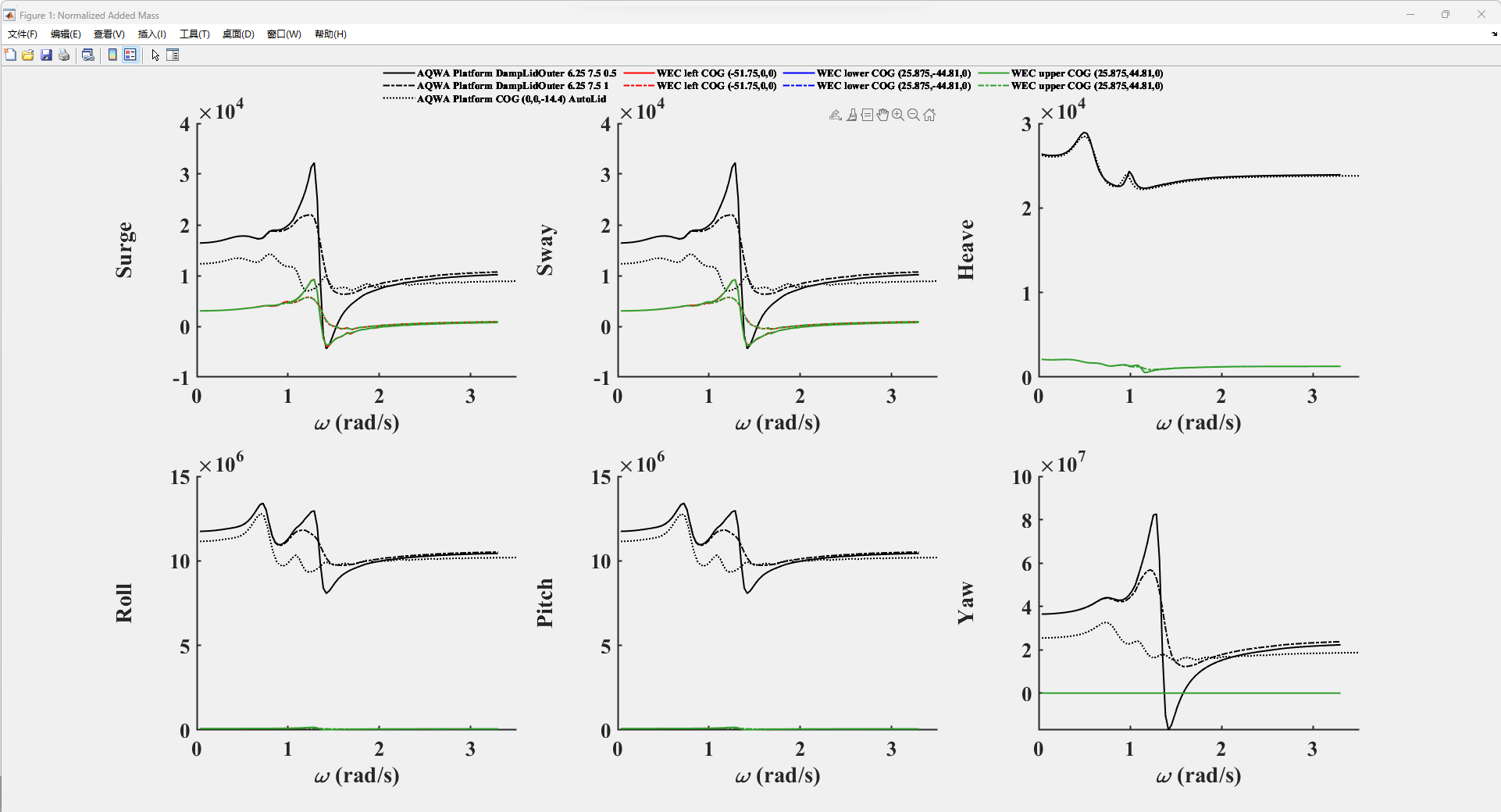

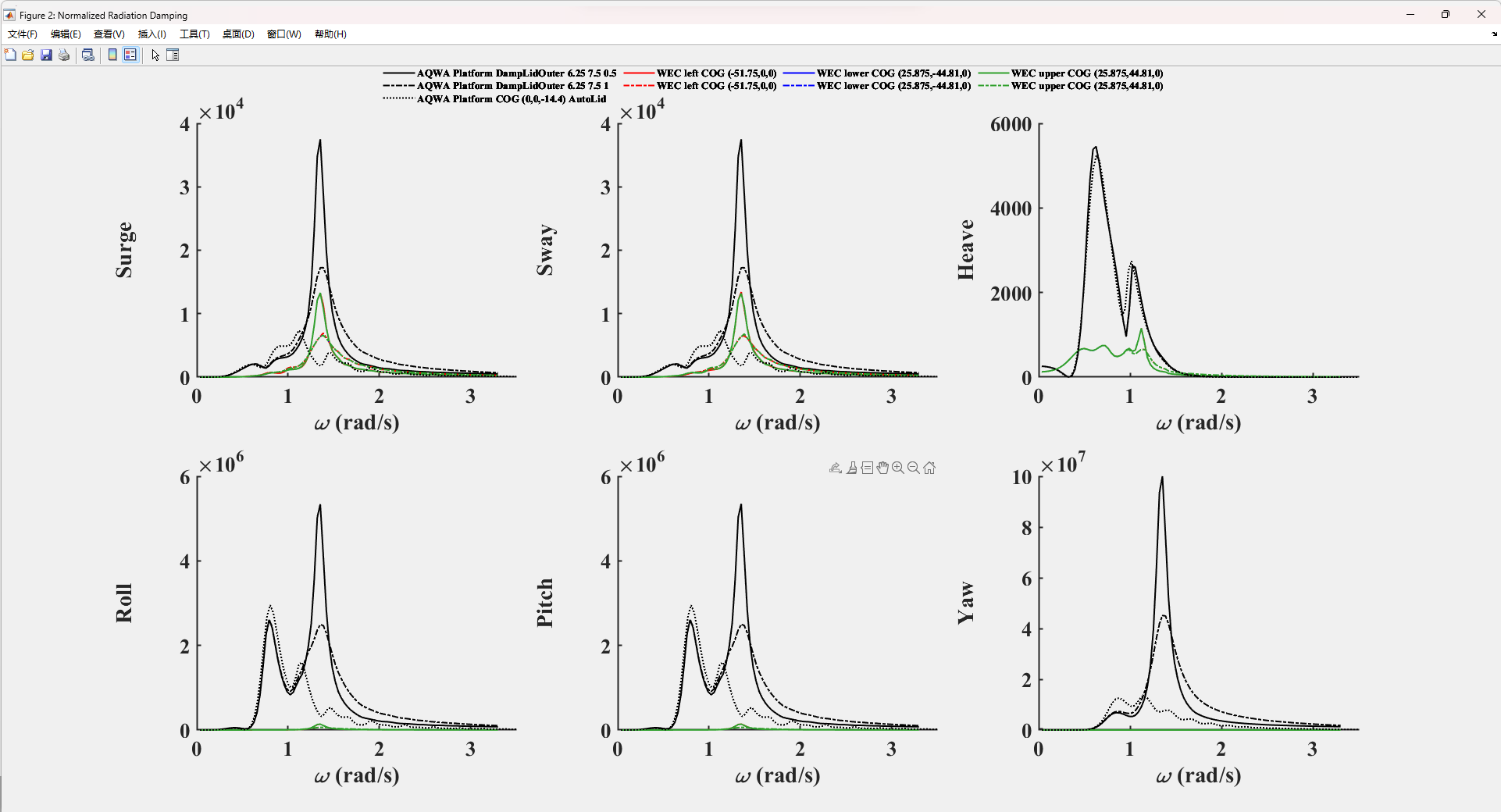

The added mass and radiation damping coefficients of single platform and multi-body cases are shown below, with different Lid Dmaping Factors of 0.5 and 1 of external lid. The hydrodynamic coefficients are in the main diagonal (i,i), i = 1:24.

I’m wondering if the subsidiary objects affect the hydrodynamic coefficient of the main body (platform)? From the above figures, the subsidiary objects indeed change the hydrodynamic coefficients of the platform. Is it related to the reflected wave?

In addtion, It is difficult to determind the Lid Dmaping Factor. The Lid Dmaping Factor of 0.5 even induces the negative added mass cofficients in the surge and sway directions, while the Lid Dmaping Factor of 1 does not seem to be desirable either!

Do you have any insights into this issue?

Looking forwards to hearing from you

Best regards,

Tianyuan

-

September 12, 2023 at 11:12 am

Mike Pettit

Ansys EmployeeHello,

The lid damping factor is an empirical value - generally we recommend that you adjust the damping factor so that the simulation results match the experimental data. That being said, damping factors of 0.5 and 1.0 are quite large - we would usually expect values in the range [0.01 - 0.1]. It may be useful to run the hydrodynamic analysis with the External Lid surfaces suppressed, to gain a better understanding of their effect on the solution.

The Hydrodynamic Diffraction Structure Selection allows you to collect structures into one or more Interacting Structure Groups. If all of the structures are grouped together (this is the default behaviour), then the radiation and diffraction effects of the subsidiaries will affect the hydrodynamic properties of the main platform, as you observe.

I hope this helps.

Cheers, Mike

-

October 6, 2023 at 12:54 pm

Tianyuan Wang

SubscriberDeal Mike

Sorry for my late reply. I seem to be having some problems with my mailbox and your replies are not alerting.

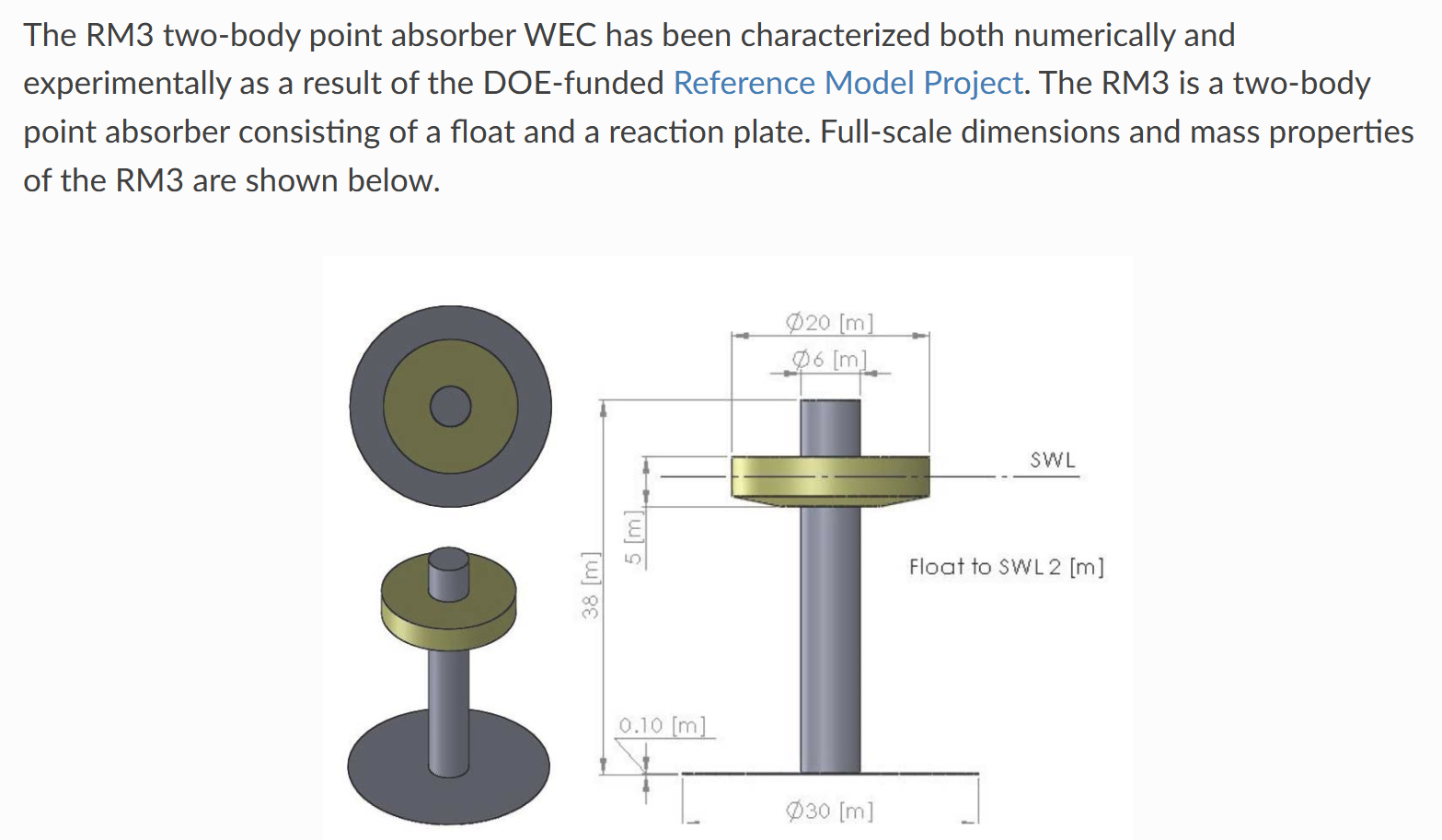

Let's discuss AQWA's workflow for the multi-body problem. For a coaxial double-buoy device, e.g., RM3, the two bodies are allowed to move relative to each other in the heave direction.

In the linear frequency-domain calculations, the wave-excitation loads are obtained by fixing the two objects without any motion. On the other hand, the wave-radiation loads are obtained by forcing one of the objects to move with unit ampitude in one direction. For example, added mass coefficient matrix of the two objects has a size of 12*12. Added mass A(3,3) is obtained by forcing object 1 to move with unit ampitude in the heave direction, and A(3,9) is the added mass imposed on object 2 by the forced motion of object 1 in the heave direction.

However, due to the rigid constraint between the two bodies, I don’t think the added mass and radiation damping can be implemented in the surge direction. Specifically, the added mass A(1,1) is obtained by forcing object 1 to move with unit ampitude in the surge direction, and A(1,7) is the added mass imposed on object 2 by the forced motion of object 1 in the surge direction. Likewise, A(7,7) is obtained by forcing object 2 to move in the surge direction, and A(7,1) is the added mass imposed on object 1 by the forced motion of object 2 in the surge direction. Considering the existence of rigid constraints between the two bodies, should the radiation coefficients be calculated in the surge, sway, roll, pitch and yaw directions? For the outer bodies with a moonpool, the forced motions of one of the two objects in the five directions would cause large-amplitude radiation waves, especially for small gaps between them.

For the RM3 device with a structural height of 38 m, radiation waves generated by the forced motion of inner body in the pitch direction are monitored to be as high as a few hundred meters, and the radiation waves generated by that in the surge direction are tens of meters. This is obviously not normal. I think it has something to do with the forced motion of a single object. Can AQWA implement constraints between two objects in frequency-domain calculations, and could you please give me some suggestions on this issue?

Best regards,

Tianyuan

-

October 23, 2023 at 1:31 pm

Mike Pettit

Ansys EmployeeHi Tianyuan,

You can create constraints between structures in the Hydrodynamic Diffraction analysis by using one or more linear Connection Stiffness matrices. These can be defined between the ground and a structure, or between two structures. For example, if you create a Connection Stiffness matrix between the float and the central column, then define large values for X-X, Y-Y, RX-RX, RY-RY, RZ-RZ and leave all other terms as zero, the float will be constrained so that its relative motion with respect to the column is almost completely in the Z direction.

Connection Stiffness only affects the Hydrodynamic Diffraction analysis. It is assumed that the effect of the Connection Stiffness is replaced by actual modelled connections (e.g. an arrangement of fenders) in any downstream Hydrodynamic Response calculations.

I hope this helps!

Mike

-

-

-

September 2, 2023 at 6:01 am

Tianyuan Wang

SubscriberDear Mike

I understood the AQWA workflow. Thank you very much for your guidance.

Best regards,

Tianyuan

-

- The topic ‘Generate a lid for a torus with a moon pool’ is closed to new replies.

-

4838

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.