TAGGED: fluid-solid-heat-transfer

-

-

August 18, 2023 at 4:43 am

M Usman

SubscriberHey How can I do CFD Analysis in Fluent in which inner surface of the hollow cylinder is at high temperature and then there is a conduction from the inner surface to the outer surface and air is flowing at a very high speed like 0.5 mach to cool the body through convective heat transfer. Right now I have been successfully ale to simulate the convective heat transfer from a hot body to the air by patching temperature value to the body. But now the temperature should be on the inner surace only and conduction and convection should happen simultaneously.

-

August 18, 2023 at 6:26 am

Essence

Ansys EmployeeHello,

You can try performing CHT by meshing the solid zone and applying the required temperature on the inner surface.

-

August 18, 2023 at 6:40 am

M Usman

SubscriberThe Conjugate heat transfer occurs by patching the temperature on the body or zone. If I apply temperature in wall boundary conditions on the surface, then that method does not work.

-

August 18, 2023 at 7:09 am

Essence

Ansys EmployeeThen, why don't you do one thing? Create a very thin concentric cylinder at the inner surface of the already existing cylinder and patch that newly created cylinder with the desired inner surface temperature.

-

August 18, 2023 at 11:55 am

M Usman

SubscriberYes, I am currently simulating exactly this.

-

August 21, 2023 at 5:00 am

M Usman

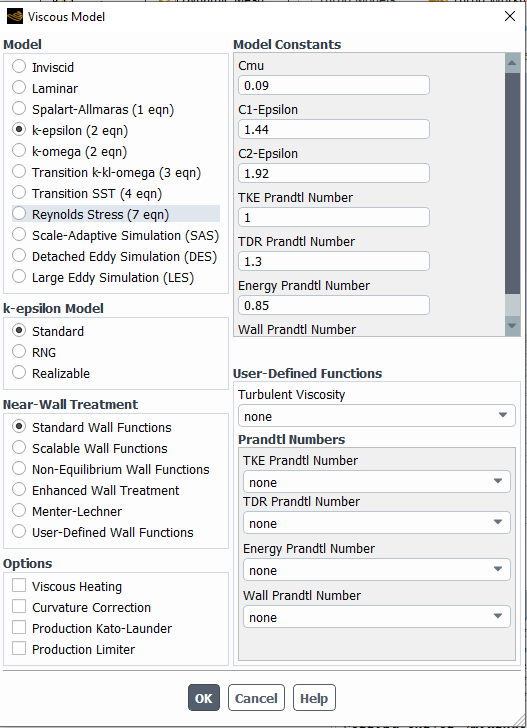

SubscriberCan you please specify which Viscous Model I should use to simulate this. Also how can I validate my results.

-

August 21, 2023 at 5:37 am

Essence

Ansys EmployeeWell, that depends on many factors. I would suggest k-w SST which is a default model in Fluent and is recommended for many numerical simulations.

-

August 22, 2023 at 11:16 am

-

August 22, 2023 at 11:55 am

Essence

Ansys EmployeeIf you observe the residuals, it clearly specifies divergence of the solution. Divergence can occur due to many reasons. For example, the mesh or the case setup.

-

August 22, 2023 at 12:59 pm

M Usman

SubscriberI tried multiples times, only CHT approach fails on this. Also meshing and Inflation are not a problem as per my experience and knowledge. Also can you explain about case setup?

-

August 22, 2023 at 3:17 pm

Essence

Ansys EmployeeWhich version are you using? What material properties options have you chosen? Please specify what Methods and Controls you have set.

-

August 23, 2023 at 4:28 am

M Usman

SubscriberI am using 2022 R2, Barrel Material is Steel chosen from Fluent Database. Fluid is air. Tried both K-omega and K-epsilon Viscous Models.

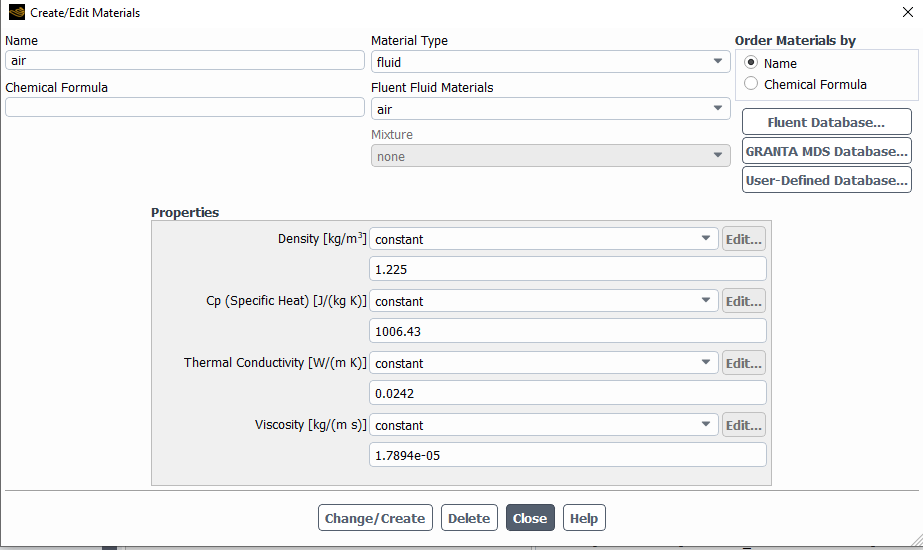

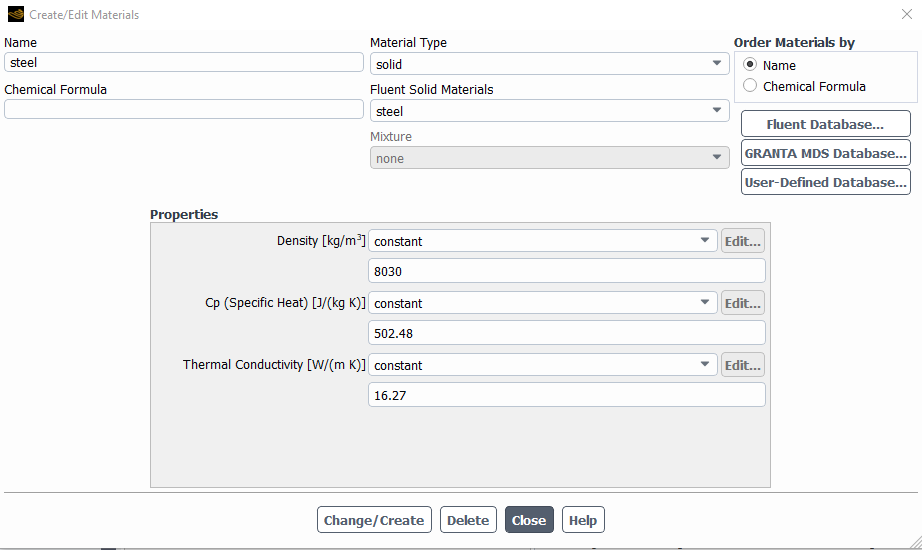

Materials:

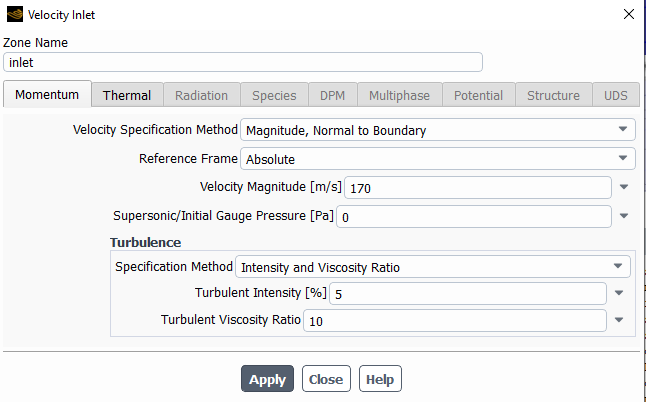

Boundary Condiitions:

Air with 25 degree celcius temperature and 0.5 Mach Speed

Pressure Outlet

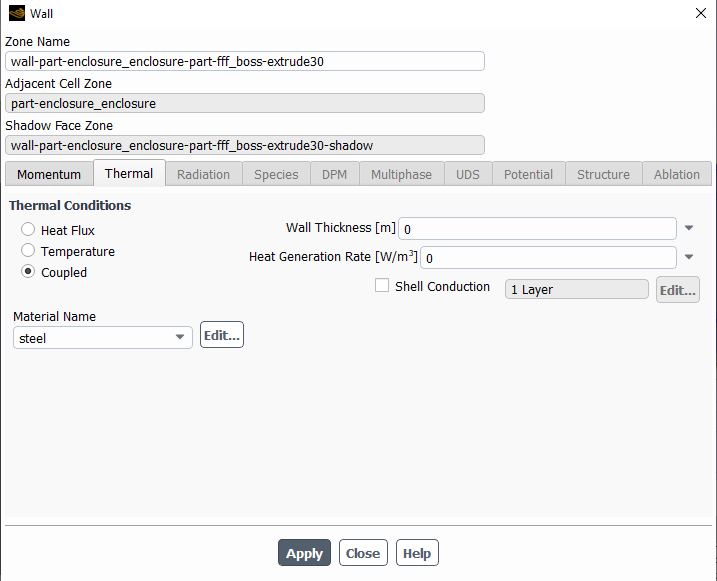

Walls:

Coupled

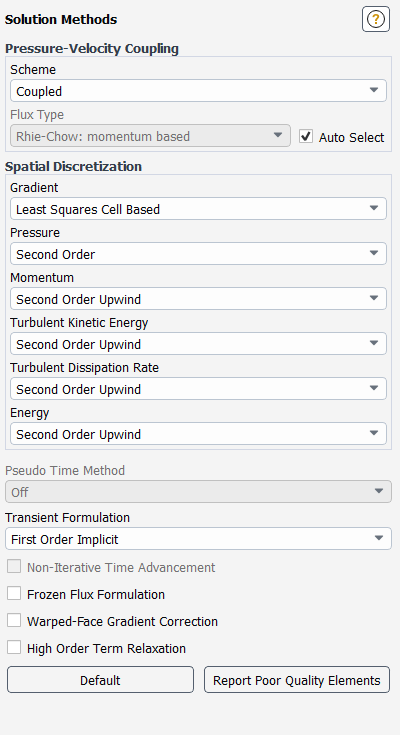

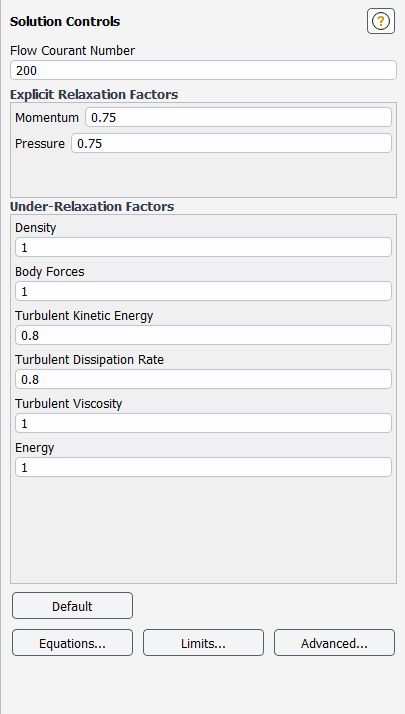

Method:

Controls (Default):

Patched Temperatur to very thin inner cylinder after initialization

-

August 23, 2023 at 4:55 am

Essence

Ansys EmployeeUse SST k-w model. If the mesh is not so good, use Warped-Face Gradient correction, Use 10-50 Courant number until the solution gets stable and converges. Then gradually increase it till 100-150. Use First Order for the spatial discretization and once the solution gets converged, move on to second order. Reduce the URFs to 0.25 until the solution gets stable and converges. Then gradually increase to default.

Try using temperature dependent properties for air instead of constant values.

-

August 25, 2023 at 6:46 am

Essence

Ansys EmployeeAdding to my reply, I think you might need to fix the temperature values in the thin inner cylinder instead of patching it.

-

August 25, 2023 at 10:34 am

M Usman

SubscriberI previously tried applying the temperature on wall but Conjugate Heat Transfer does not happen as result become constant. And then I got a suggestion from here that I should patch the temperature on the body and that worked and only because of this I have to create a very thin cylinder otherwise in actual, I only had to apply the temperature on the inner wall of the barrel.

-

August 25, 2023 at 10:43 am

Essence

Ansys EmployeeI am referring to fix the temperature to the whole inner thin cylinder. You can do this in Cell Zone conditions. Patching is different.

-

August 28, 2023 at 4:43 am

M Usman

SubscriberI have tried this approach as well but when I display the contours after initializing, the temperatures on the bodies do not get updated but when I patch the temperature, contours get updated. Also the recommendations you wrote to avoid the floating point exceptionor divergence worked in one case but when I slightly changed the geometry, the same error is appearing again. I have tried changing method and oter parameters but nothing worked.

-

August 28, 2023 at 9:53 am

Essence

Ansys EmployeeDid you check them after running the case for few iterations after fixing and initializing?

For divergence, it shows that, there maybe some defects which needs to be repaired. As I told you, there are many reasons for that.

-

August 29, 2023 at 9:45 am

M Usman

SubscriberOk sure I will check

-

- The topic ‘Conduction Plus Convection Heat Transfer’ is closed to new replies.

-

5049

-

1764

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.