-

-

August 14, 2023 at 11:28 am

-

August 14, 2023 at 11:34 am

peteroznewman

SubscriberThe best way to find the noise generated by the compressor is to measure it with a Sound Level Meter.

The manufacturer may list the noise on their spec sheet. If not you might contact them and ask for this data.

-

August 16, 2023 at 4:31 am

Hakim Dina Anjum

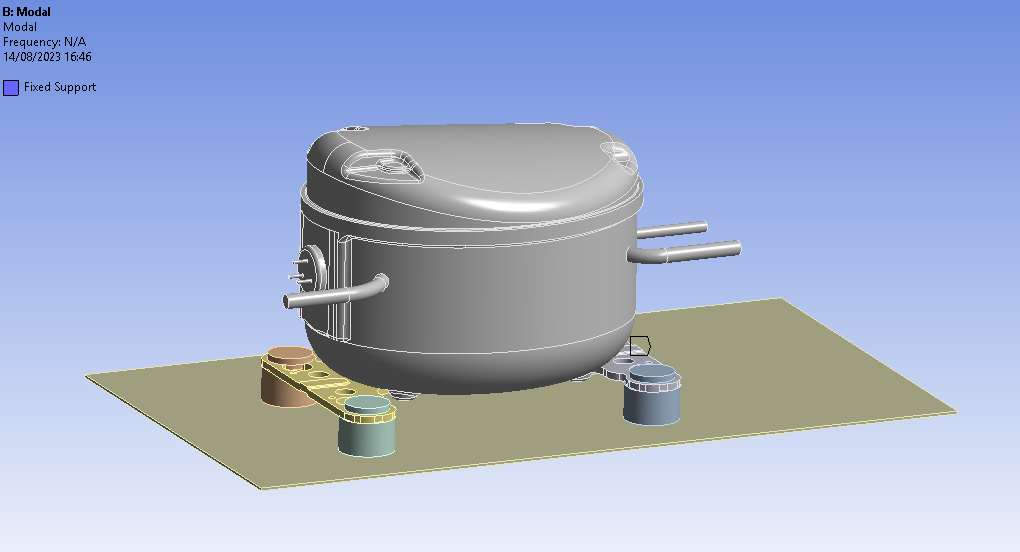

SubscriberThank you, Peter. I have the tested data. To clarify, I want to find the noise generated by the compressor through simulation. One of many end goals is to find the optimum tightening torque of the bolts used to bolt the compressor to the base plate during assembly, such that the compressor vibration noise is at a minimum.

-

August 16, 2023 at 10:45 am

peteroznewman

SubscriberDo you have access to accelerometers and the data acquisition system to record the vibration on the surface of the compressor? To simulate sound pressure level (SPL) in the air around an object that is vibrating, you need to know the vibration magnitude and frequency of the surfaces on the object.

Bolts that fasten a compressor to a large flat plate can incease the noise level. Vibration is transfered to the plate which will have different natural frequencies than the compressor and a large surface area to create noise in the air. Vibration isolation supports are often added to a design to limit how much vibration transfers into the plate the compressor is mounted to. Even without vibration isolation supports, changing the thickness of the plate could have an impact on the noise sent into the surroundings.

Bolts in the presence of vibration tend to become loose if they are not torqued properly. I doubt lower torque will have any effect on the noise, but it could result in a fatigue failure of one of the bolts in the lifetime of the compressor.

You could separate the contribution of the mounting plate to the total environmental noise from the noise coming from the compressor itself if you were to hang the compressor from wires and measure the noise, or at least put a large thick foam pad on the floor under the compressor that has no large plate bolted to it.

You could put an enclosure around the compressor to reduce the noise being sent into the environment.

If your goal is to reduce the noise, an experimental approach is best.

If your goal is to learn to use acoustic simulation software, choose a simple problem where you can simulate the vibration of the object creating the sound. That is what I did 4 years ago when I made this video.

-

August 16, 2023 at 12:27 pm

Hakim Dina Anjum

SubscriberMy end goal is to find the effect of various variables through simulation, eventually reduce the noise by implementing the feasible ones. Experimental approach is definitely the better way, but it is not feasible to run such lengthy noise level tests in my lab for "experimental" purposes. Above that, there are just too many variables to isolate.

Using vibration isolating supports was a nice observation. In fact, the effect of the stiffness of the rubber grommets used here is also another analysis I plan to conduct later on. That's another discussion. Changing the plate thickness might work but again, it is one of many of other variables.

Effect of tightening torque on the bolts do play a role in the vibration of the compressor as analyzed by our technical experts, a stiffer compressor is prone to higher vibration.

Using accelerometers has been considered as plan B, as I do not have direct access to it. Also, I believe similar questions will arise as to "How" to input that data as a boundary condition in a harmonic response analysis.

Thank you for the tutorial on the tuning fork. I had taken a similar approach in conducting a trial simulation of the compressor, providing a "Dummy force" on it after going through other acoustics tutorials available in the ANSYS Learning Hub and other sources. Further study on it will go nowhere unless I figure out how to input the boundary conditions first, be in the compressor rps or the surface vibration data.

-

- The topic ‘Compressor RPS in Harmonic Response’ is closed to new replies.

-

5274

-

1885

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.